623H WHEEL TRACTOR-SCRAPER

Quick loading, high travel speeds and the ability to load and dump on the run yield fast cycle times, allowing Cat Wheel Tractor-Scrapers to consistently deliver high productivity at the lowest cost per ton.

SPECIFICATIONS

Flywheel Power: Tractor/Scraper304 kW (407 hp)

Max. Power304.0 kW

TractorCat® C13 ACERT™

BENEFITS AND FEATURES

power train engine

The Cat® C13 ACERT™ engine is built for power, reliability and efficiency.

LEARN MOREengine

Flywheel Power: Tractor/Scraper304 kW (407 hp)

Max. Power304.0 kW

TractorCat® C13 ACERT™

scraper bowl

Scraper Capacity: Heaped17.6 m3

Rated Load25038.0 kg

Heaped Capacity17.6 m3

Maximum Depth of Cut262.0 mm

Maximum Depth of Spread465.0 mm

Maximum Ground Clearance at Cutting Edge529.0 mm

Maximum Hydraulic Penetration Force590.0 kN

Struck Capacity14.4 m3

Thickness of Cutting Edge22.0 mm

Width of Cut, Outside Router Bits3136.0 mm

transmission

Top Speed (Loaded)53.9 km/h

1 Forward5.0 km/h

2 Forward8.9 km/h

3 Forward12.1 km/h

4 Forward16.3 km/h

5 Forward21.9 km/h

6 Forward29.6 km/h

7 Forward39.9 km/h

8 Forward53.9 km/h

Reverse9.2 km/h

steering

Steering Angle - Right85º

Steering Angle - Left82º

hydraulics

Bowl Cylinder Bore140.0 mm

Bowl Cylinder Stroke845.0 mm

Ejector Cylinder Bore110.0 mm

Ejector Cylinder Stroke1213.0 mm

Bowl Floor Cylinder Bore130.0 mm

Bowl Floor Stroke1353.0 mm

Cushion Hitch Circuit Flow40.1 L/min

Cushion Hitch Cylinder Bore140.0 mm

Cushion Hitch Cylinder Stroke251.0 mm

Elevator Circuit Flow257.0 L/min

Scraper Circuit Flow192.0 L/min

Secondary Steering Circuit Flow39.0 L/min

Steering Circuit Flow234.0 L/min

Steering Cylinder Bore127.0 mm

Steering Cylinder Stroke1128.0 mm

standards

StandardsStandards

weights machines meeting us epa tier 4 interimeu stage iiib emission standards

Loaded, based on a rated load64975.0 kg

Operating Weight - full fuel tanks39937.0 kg

Shipping Weight - 10% Fuel39259.0 kg

service refill capacities tractor

Cooling System64.0 L

Differential173.0 L

Engine Crankcase33.0 L

Final Drive (per side)19.0 L

Hydraulic Reservoir83.0 L

Transmission70.0 L

Windshield Washer Reservoir5.0 L

weights machines achieving prior us epa tier 3eu stage iiia emission levels

Loaded, based on a rated load64728.0 kg

Operating Weight - full fuel tanks39689.0 kg

Shipping Weight - 10% Fuel39011.0 kg

service refill capacities scraper

Fuel Tank763.0 L

Non-Powered Wheel4.0 L

tractor engine prior us epa tier 3eu stage iiia configuration*

Bore130.0 mm

Displacement12.5 L

Max. Power (All Gears) (ISO 14396)304.0 kW

Max. Power Reference Engine Speed1700.0 RPM

Stroke157.0 mm

Tractor EngineCat® C13 ACERT™

tractor engine us epa tier 4 interimeu stage iiib

Bore130.0 mm

Displacement12.5 L

Max. Power (All Gears) (ISO 14396)304.0 kW

Max. Power Reference Engine Speed1700.0 RPM

Stroke157.0 mm

Tractor EngineCat® C13 ACERT™

BENEFITS AND FEATURES

POWER TRAIN - ENGINE

The Cat® C13 ACERT™ engine is built for power, reliability and efficiency.

LEARN MORE

INTEGRATED TECHNOLOGIES

Technology options to improve operator comfort and increase productivity.

LEARN MORE

623H STANDARD EQUIPMENT

- power train tractor

C13 ACERT engine with MEUI

Cat Engine Brake

Electric start, 24 Volt

Air cleaner, dry type with precleaner

Fan, hydraulic

Diesel Particulate Filter (DPF) aftertreatment (for engine meeting U.S. EPA Tier 4 Interim/EU Stage IIIB emission standards)

Ground level engine shutdown

Radiator, aluminum unit core, 9 fins per inch

Guard, crankcase

Muffler (for engines achieving U.S. EPA Tier 3/EU Stage IIIA emission levels)

Starting aid, ether

Braking system: • Primary and Secondary, wet disc, hydraulic • Parking, hydraulically-released, spring-applied

Throttle Lock

Transmission: • 8-speed planetary powershift • ECPC Control • APECS software • Programmable top gear selection • Transmission hold • Differential lock • Guard, power train - power train scraper

C9.3 ACERT engine with high pressure common rail fuel

Cat Engine Brake

DPF aftertreatment module (for engine meeting U.S. EPA Tier 4 Interim/EU Stage IIIB emission standards)

Electric start, 24 volt

Fan, driveline

Ground engine shutdown

Muffler (for engines achieving prior U.S. EPA Tier 3/EU Stage IIIA emission levels)

Starting aid, ether

Braking system: • Primary and Secondary, wet disc, hydraulic • Parking, hydraulically-released, spring-applied

4-speed (torque converter drive) transmission, planetary powershift - electrical tractor

Alternator, 150 Amp

Batteries (4), 12 Volt, 1,000 CCA, maintenance free, high output

Electrical system, 24V

Lighting system: • Headlights, halogen • Turn signals with hazard function • LED Floodlights, halogen (2), cutting edge (1), bowl (2), side vision (2)

Starting/charging receptacle - electrical scraper

Alarm, backup

Alternator, 65 Amp

Batteries (4), 12 Volt, 1,000 CCA, maintenance free, high Output

Lighting system: • Brake lights, LED • Turn signals with hazard function, LED

Starting/charging receptacle - operator environment tractor

HVAC system, heat, AC, defrost

Thermostat control of HVAC system

Coat hook

Lunchbox platform with holding strap

Diagnostic connection (2)

12V power ports (2)

Differential lock (1)

Dome courtesy light

Horn, electric

T-Handle implement control

Mirror, rearview

Radio ready, 12V

ROPS/FOPS cab, pressurized

Keypad switches

Safety tab rocker switches

Parking brake

Seat belt, static two-piece

Seat, air suspension, Comfort Series 3, rotates 30 degrees

Steering wheel, tilt, telescoping, padded

Storage in dash if WAVS or Cat Grade Control is not equipped

Windows, right side emergency egress

Windows, sliding

Windows, laminated, zipped in

Windshield wipers, front and rear windows, includes washers

Door lock

Messenger Display - gauges, warnings include: • Coolant temp • Engine oil temp • Hydraulic oil temp • DPF temp • Fuel level • Park brake • Implement lockout • Brake system • Regeneration required • Throttle lock • System voltage • Secondary steering • Bail down • Differential lock • Apron float • Transmission hold • Cushion hitch • High beam lights • Action lamp • Engine speed, rpm • Gear selection out • DPF fill levels - fluids

Extended Life Coolant to -37° C (-34° F) - other standard equipment tractor

Cushion hitch

Accumulators (cushion hitch) with Canadian Registration Number (CRN)

Fast oil change

Fenders, non metallic

Heater, engine coolant 120V

Tow pin, front

Vandalism locks - other standard equipment scraper

Quick drop bowl valve

Vandalism locks

Elevator with 15 flights

623H OPTIONS

- sequence assist

- cat grade control

- secondary steering

- powered access ladder

- cat active ride management arm seat

- fast fuel fill

- hid work lights

- low ambient fluids 51° c 61° f

- work area vision system wavs three cameras showing right side cutting edge and directly behind machine display in cab

- external steering lock

- cab precleaner

- cab rotating beacon

- air horn

- fender extension scraper

MOTEUR

Ergonomically designed for all-day comfort, control and productivity.

BENEFITS AND FEATURES

Ergonomic Layout The all new H Series operator station is ergonomically designed for total machine control in a comfortable, productive and safe environment. All controls, levers, switches and gauges are positioned to maximize productivity and facilitate a reduction in operator fatigue.

Viewing Area Designed for excellent all-around visibility and clear sight lines to the job site, the large viewing area offers exceptional visibility to the front of the machine as well as to the cutting edge. The air conditioning unit has been relocated to beneath the cab, allowing the operator enhanced visibility.

High productivity from a comfortable, confident operator.

BENEFITS AND FEATURES

Spacious Cab With a 21% larger cab, H Series scrapers offer a comfortable working space. The larger cab and wider door make getting in and out of the cab easier. The increased glass area enhances visibility around the machine.

Steering Column The steering column and pedals have been relocated for more comfortable operation when the seat is angled during machine operation. The telescopic and tilt adjustable steering column maintains a comfortable driving position regardless of operator size.

Standard Comfort Features The H Series cab is equipped with features designed to maintain operator comfort. Standard comfort features include: coat hook, lunchbox storage platform with strap, air conditioning, heat, and radio-ready.

Seat Options H Series scrapers use the Cat Comfort Seat with additional travel to allow the operator to position themselves for optimal comfort and productivity. The seat rotates up to 30 degrees to the right for a more comfortable position during loading and 30 degrees to the left to make getting in and out of the cab easier. For unparalleled ride comfort, H Series scrapers are equipped with the Cat Advanced Ride Management (ARM) seat suspension which uses an active suspension to dampen vibration and minimize end-of-stroke shock loads to the operator.

Integrated Technologies The optional Sequence Assist and Cat Grade Control automate many repetitive operator tasks.

T-Handle Implement Control Lever The redesigned control lever puts all of the scraper functions in the palm of the operator’s hand. The low-effort lever and convenient push-button and thumb wheel controls are ergonomically placed for minimum arm movement.

The Cat® C13 ACERT™ engine is built for power, reliability and efficiency.

BENEFITS AND FEATURES

ACERT Technology The Cat® C13 ACERT™ engine continues the evolutionary, incremental improvements that provide breakthrough engine technology built on systems and components developed by Caterpillar with proven reliability. The engine is available with either U.S. EPA Tier 3/EU Stage IIIA equivalent emission configurations or U.S. EPA Tier 4 Interim/EU Stage IIIB certified emission configurations to meet the needs of contractors around the world.

Emissions Machines equipped with engines meeting U.S. EPA Tier 4 Interim/EU Stage IIIB emission standards are equipped with a Cat Clean Emission Module to deliver the performance and efficiency that customers demand while meeting emission requirements. Machines equipped with the U.S. EPA Tier 3/EU Stage IIIA equivalent engines are equipped with a muffler in place of the Cat Clean Emission Module.

Cat Clean Emission Module (CEM) CEM is an exhaust aftertreatment package consisting of a diesel particulate filter, and control systems. The CEM reduces particulate emissions using passive and active regeneration during normal engine operation.

Cat NOx Reduction System (NRS) The Cat NOx Reduction System (NRS) captures and cools a small quantity of exhaust gas, then routes it into the combustion chamber where it drives down combustion temperatures and reduces NOx emissions.

Diesel Particulate Filter Regeneration Regeneration is the removal of soot from the Diesel Particulate Filter (DPF). The Aftertreatment Regeneration Device (ARD) is used to regenerate the DPF. The DPF traps both particulates and ash, the ash is removed at regular service intervals.

More power to the ground for greater productivity.

BENEFITS AND FEATURES

Electronic Transmission The Cat eight-speed forward one-speed reverse Electronic Clutch Pressure Controlled (ECPC) transmission features enhanced shift control logic with anti-hunt shift strategy for speed continuity, and to ensure constant shift times.

- Tractor gears 1-2 - converter drive for increased torque, gears 3-8 - direct-drive for drive train efficiency.

- Transmission Hold maintains converter drive for maximum rimpull or holds current gear for best control.

- Programmable Top Gear manually sets top gear available (3rd-8th) to match conditions or speed.

- Neutral Coast Inhibitor prevents transmission shifts into neutral while moving.

Smooth Transmission Gear Shifting The 623H features ECPC Shift Torque Management (STM), with improved Shift Control Logic (SCL) and Part Throttle Shifting (PTS). These features allow smoother shifting and greater acceleration on grades while torque is maintained through the shift changes. SCL also provides automatic shift selection that is more specific to the desired machine operation, and downshifts when needed for maximum acceleration when increased throttle is applied. PTS allows shifting at lower speeds during part throttle operation, resulting in improved part throttle fuel economy, quieter machine operation, and better maneuvering in reduced speed operating conditions.

Brake Performance The 623H uses hydraulically-actuated wet disc brakes for exceptional brake performance. The standard Cat Engine Brake reduces brake wear and enhances machine control.

Superior design and construction delivers long term durability.

BENEFITS AND FEATURES

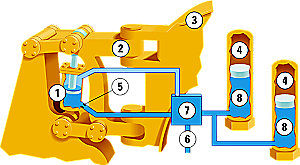

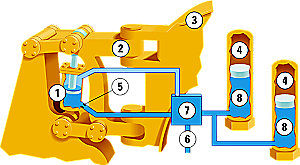

Cushion Hitch Electronically actuated with parallelogram-type linkage for exceptional strength, with two nitrogen accumulators (4) using free-floating pistons (8) to deliver a smooth ride for enhanced operator comfort and machine durability.

- controlled oil flow (6) dampens rebound oscillation

- leveling valve (7) applies pressure via an orifice (5) to automatically center the piston in load cylinder (1)

- steel castings are used to eliminate many welded joints and increase strength

- double-kingbolt design (2, 3) withstands high external forces, simplifies installation and removal

Lockout Switch An operator-selectable lockout switch, located on the joystick, locks the cushion hitch down for improved control of the cutting edge during loading and dumping.

Nitrogen Accumulator Vertically mounted hydraulic cylinder transfers road shocks to nitrogen accumulators. Nitrogen accumulator absorbs and dampens road shocks, thus preventing the loads from being transmitted to the hitch components or to the operator.

Non-Metallic Fenders and Fuel Tank The new fuel tank is made of recyclable roto-milled polyethylene and keeps the fuel cleaner with controlled filtration and cleanout access ports. The new capacity of the new fuel tank has been increased, providing operators with 10 plus hour shifts depending on engine load factors. The new tractor fenders are made of the same highly durable, roto-milled polyethylene. The non-metallic fenders prevent material buildup when operating in sticky materials.

Caterpillar designed and built for rugged performance and reliability.

BENEFITS AND FEATURES

Redesigned Bowl The structure of the bowl sidewalls, ejector and floor have been improved for improved durability. New floor door rollers are used for longer life. The bowl uses a low profile design offering low resistance to incoming materials.

Ejection System The powerful ejection system provides constant spreading control while minimizing carryback material. The floor of the bowl retracts as the ejector moves forward, allowing the operator to precisely control the flow of material.

Cutting Edges and Cat Ground Engaging Tools (GET) A variety of Ground Engaging Tools (G.E.T.) options are available to optimize the machine for different material types and loading conditions. GET options include standard, serrated, and Abrasion Resistant Material (ARM). Most are reversible to provide long life and reduced operating costs. Contact your Cat dealer to learn more about the best tools for your applications.

Material Application The 623H is ideal for windrowing, blending material as well as breaking up vegetation in stripping operations.

The stronger elevator makes the 623H capable of far more than finish work.

BENEFITS AND FEATURES

Material Handling The elevator lifts material off of the cutting edge and carries it to the top of the elevator and then dumps the material into the bowl. Blending the material helps eliminate voids in the bowl for consistent payloads and uneven loading.

Closed Loop Elevator Hydraulic System The 623H elevator power has been increased by a new variable displacement piston pump and fixed displacement motor in a closed-loop circuit. The increased power enables the operator to take deeper cuts and load in a shorter distance with less elevator stall.

Redesigned Elevator Structures The 623H elevator and chain life has been improved through structural improvements to the elevator structure. Wear plates are used in place of rollers for reduced chain stretch.

New Elevator Controls The elevator is engaged with a thumb roller on the joystick. The operator can choose one of seven forward and four reverse speeds to match the speed that best matches the material.

Chain Adjustment Serviceability is enhanced through a new chain adjustment mechanism. The new scissors-style chain adjuster uses a simple tool to tighten the chain in 2.54 cm (1.0 in) increments.

Elevator Flights The life of the 15 elevator flights is improved in abrasive materials through the addition of high-strength, wear-resistant steel on the face of each flight.

Technology options to improve operator comfort and increase productivity.

BENEFITS AND FEATURES

Sequence Assist Sequence Assist uses integrated software and position-sensing cylinders to automate many of the tasks an operator performs when loading, hauling and dumping. The operator simply sets preferences for bowl and apron height and subsequently pushes a button to ready the machine for loading, then hauling, then dumping, and then the return to cut. The system automatically sets the cushion hitch, bowl height, ejector and elevator. Sequence Assist comes with a convenient load counter for tracking material moved. With Sequence Assist, up to 14 individual implement and machine commands are replaced by four touches of a button, allowing the operator additional time to prepare for the loading cycle and observation of the job site.

Cat Grade Control Cat Grade Control is an automatic system that helps you control costs by moving the maximum amount of material with the prime earthmover which often provides the lowest cost per unit of material moved. Using satellite positioning technology, the automatic system ensures cut protection by limiting how deep the scraper will dig. The optional system is available from the factory and fully integrated into the machine and works seamlessly with Sequence Assist. Additional benefits of Cat Grade Control include putting the site plan in front of the operator for increased efficiency and elimination of rework and using the scraper for site mapping.

Work Area Vision System (WAVS) Cameras on the machine provide views of the cutting edge, right side and rear. The system enhances safety and provides a new way to see the cutting edge during loading and to see to the rear of the machine when performing push-load or push-pull work with another scraper.

Cat® dealer services help you operate longer with lower costs.

BENEFITS AND FEATURES

Selection Make comparisons of the machines you are considering before you buy. Your Cat® dealer can help.

Purchase Consider the resale value, compare productivity and day-to-day operating costs and fuel consumption.

Operation For the best operating techniques to increase productivity and your profit, turn to your Cat dealer for the latest training literature and trained staff.

Maintenance Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as S·O·SSM and Technical Analysis help you avoid unscheduled repairs.

Replacement Repair or rebuild? Your Cat dealer can help you evaluate the costs so you can make the right choice.

Product Support Your local Cat dealership will be with you every step of the way with its unsurpassed worldwide parts support, trained technicians and customer support agreements.

Safety is an integral part of all machine and system designs.

BENEFITS AND FEATURES

Powered Access Ladder A new powered access system option significantly reduces the effort required to climb into the cab. The system is a solid, stable angled ladder that folds out from underneath the cab. It is activated from a keypad located behind a service door at ground level. Controls are also located in the cab on a keypad. The ladder provides a rigid and angled base of support for easier climbing and descent. For added safety, the steps are illuminated by LED lights. An actuator under the cab operates the step. When not in use, the ladder retracts under the cab. An audible alarm sounds if the machine moves while the ladder is down. If power fails on the machine, the operator can raise or lower the steps manually using a lever inside the cab or outside next to the ladder’s top step.

Access and Egress Handrails and grab irons are provided for safe and secure entrance and exit of the cab as well as for performing daily maintenance.

Work Area Vision System (WAVS) Cameras on the machine provide views of the cutting edge, right side and rear. The system enhances safety and provides a new way to see the cutting edge during loading and to see to the rear of the machine when performing push-load or push-pull work with another scraper.