906H2 COMPACT WHEEL LOADER

The new H2 Series Compact Wheel Loaders maintain the Cat strengths while boasting a whole new range of features and benefits. In short, a machine that can be trusted to perform.

engine

Net Power52.0 kW

Gross Power55.0 kW

ModelCat® C3.3B DIT

Bore94.0 mm

DescriptionCat C3.3B engine, 4 cylinder, turbocharged, direct injection

Displacement3.3 L

Net Power - 80/1269/EEC52.0 kW

Net Power - ISO 924952.0 kW

Stroke120.0 mm

weights

Operating Weight5630.0 kg

operating specifications

Rated Bucket Capacity0.9 m3

Bucket Capacity0.9 m3

hydraulic system

3rd Auxiliary Flow - Standard83.0 L/min

Hydraulic Cycle Time - Lift5 secs

3rd Auxiliary Flow - High Flow125.0 L/min

Hydraulic Cycle Time - Dump2 secs

Main Relief235.0 bar

Hydraulic Cycle Time - Rackback2.5 secs

Hydraulic Cycle Time - Lower4 secs

service refill capacities

Cooling System24.0 L

Fuel Tank52.0 L

Hydraulic System70.0 L

Engine Oil10.0 L

travel speeds

High Speed35.0 km/h

Speed 17.0 km/h

Speed 220.0 km/h

operating specifications ssl coupler

Breakout Force, Bucket (ISO 14397-2:2007)42.0 kN

Full Turn Static Tipping Load, Bucket (ISO 14397-1:2007)3160.0 kg

Operating Weight (ISO 6016:1998)5630.0 kg

Rackback, Transport Position52.0 Degrees

Rated Bucket Capacity (ISO 7546:1983)0.9 m3

Rated Operating Load at Full Turn, Bucket (ISO 14397-1:2007)1580.0 kg

Rated Operating Load at Full Turn, Forks (EN 474-3:2006, Firm and Level Ground, 1.25 Stability and 500 mm Load Center)2065.0 kg

Rated Operating Load at Full Turn, Forks (Firm and Level Ground, 1.25 Stability and 500 mm Load Center, Transport 100 mm Above Ground)2720.0 kg

Straight Tipping Load, Bucket (ISO 14397-1:2007)3985.0 kg

Tire Size405/70 R18

sound levels

Exterior SoundFor European Union compliant machine configurations, machine is measured according to test procedures specified in 2000/14/EC.

Interior SoundDynamic operator sound pressure level is 75 dB(A) when “ISO 6396:1992” is used to measure the value for an enclosed cab.

cab features comfort cab

Cabin LightStandard

Cat Radio/CD/MP3/WMA/AUXOptional

Coat HookStandard

External Knock Back MirrorsStandard

Fixed Steering ColumnStandard

Heated Rear WindowStandard

HeaterStandard

Heater and Air ConditioningOptional

Left Window - FixedStandard

Lockable Storage BoxStandard

Radio-ready Kit (Wiring, Speaker, Aerial and Grilles)Standard

Rear BlindOptional

Right Window - SlidingStandard

Sun VisorStandard

Vinyl Suspension SeatStandard

dimensions with horizontal pin coupler

Articulation Angle (Degrees)39.0 Degrees

Cab Height2465.0 mm

Departure Angle (Degrees)34.0 Degrees

Dig Depth80.0 mm

Dump Angle at Maximum Height (Degrees)45.0 Degrees

Fork Depth Below Ground25.0 mm

Fork Height at Maximum Reach1425.0 mm

Fork Reach at Maximum Height445.0 mm

Ground Clearance300.0 mm

Hinge Pin at Maximum Height3230.0 mm

Load Over Height3035.0 mm

Machine Width1840.0 mm

Maximum Dump Height2510.0 mm

Maximum Fork Height3090.0 mm

Maximum Reach1215.0 mm

Overall Length with Bucket5435.0 mm

Overall Length with Forks5915.0 mm

Reach at Ground Level720.0 mm

Reach at Maximum Dump Height710.0 mm

Tire Gauge1420.0 mm

Turning Radius Inside Tire2240.0 mm

Turning Radius Over Bucket4400.0 mm

Wheelbase2170.0 mm

Width Over Bucket1880.0 mm

dimensions with ssl coupler

Articulation Angle (Degrees)39.0 Degrees

Cab Height2465.0 mm

Departure Angle (Degrees)34.0 Degrees

Dig Depth90.0 mm

Dump Angle at Maximum Height (Degrees)45.0 Degrees

Fork Depth Above Ground45.0 mm

Fork Height at Maximum Reach1490.0 mm

Fork Reach at Maximum Height505.0 mm

Ground Clearance300.0 mm

Hinge Pin at Maximum Height3230.0 mm

Load Over Height3025.0 mm

Machine Width1840.0 mm

Maximum Dump Height2395.0 mm

Maximum Fork Height3160.0 mm

Maximum Reach1265.0 mm

Overall Length with Bucket5585.0 mm

Overall Length with Forks5945.0 mm

Reach at Ground Level750.0 mm

Reach at Maximum Dump Height810.0 mm

Tire Gauge1420.0 mm

Turning Radius Inside Tire2240.0 mm

Turning Radius Over Bucket4445.0 mm

Wheelbase2170.0 mm

Width Over Bucket1880.0 mm

maximum material densities multi purpose

Bucket Weights - Horizontal Pin BOCE557.0 kg

Bucket Weights - Vertical Pin BOCE534.0 kg

Bucket Width1880.0 mm

Dump Height - Horizontal Pin Coupler2500.0 mm

Dump Height - SSL Coupler2470.0 mm

Maximum Material Density - Horizontal Pin Coupler2184 kg/m3

Maximum Material Density - SSL Coupler2131 kg/m3

Rated Capacity0.75 m3

ropsfops

StandardsCat cab, Rollover Protective Structure (ROPS) and Falling Objects Protective Structure (FOPS)

maximum material densities light material

Bucket Weights - Horizontal Pin BOCE462.0 kg

Bucket Weights - Vertical Pin BOCE461.0 kg

Bucket Width2080.0 mm

Dump Height - Horizontal Pin Coupler2430.0 mm

Dump Height - SSL Coupler2285.0 mm

Maximum Material Density - Horizontal Pin Coupler1271 kg/m3

Maximum Material Density - SSL Coupler1208 kg/m3

Rated Capacity1.2 m3

cab features deluxe cab

Cabin LightStandard

Cat Radio/CD/MP3/WMA/AUXOptional

Cloth Suspension Seat, ArmrestStandard

Coat HookStandard

External Knock Back MirrorsStandard

Fixed Steering ColumnStandard

Heated Rear WindowStandard

HeaterStandard

Heater and Air ConditioningOptional

Left Window - FixedStandard

Left Window - SlidingStandard

Lockable Storage BoxStandard

Radio-ready Kit (Wiring, Speaker, Aerial and Grilles)Standard

Rear BlindOptional

Right Window - SlidingStandard

Sun VisorStandard

cab features base cab

Cabin LightStandard

Cat Radio/CD/MP3/WMA/AUXOptional

Cloth, Electric Air Suspension, Arm/Head Rest, Lumbar Support and Heated Back SeatStandard

Coat HookStandard

External Knock Back MirrorsStandard

Heated Rear WindowStandard

HeaterStandard

Heater and Air ConditioningOptional

Lockable Storage BoxStandard

Rear BlindOptional

Right Window - SlidingStandard

Two Access DoorsStandard

Vinyl Suspension SeatStandard

cab features canopy

Adjustable Steering ColumnStandard

Cabin LightStandard

Heated Rear WindowStandard

HeaterStandard

Lockable Storage BoxStandard

Radio-ready Kit (Wiring, Speaker, Aerial and Grilles)Standard

Two Access DoorsStandard

operating specifications hp coupler

Breakout Force, Bucket (ISO 14397-2:2007)51.0 kN

Full Turn Static Tipping Load, Bucket (ISO 14397-1:2007)3400.0 kg

Operating Weight (ISO 6016:1998)5630.0 kg

Rackback, Transport Position52.0 Degrees

Rated Bucket Capacity (ISO 7546:1983)0.9 m3

Rated Operating Load at Full Turn, Bucket (ISO 14397-1:2007)1700.0 kg

Rated Operating Load at Full Turn, Forks (EN 474-3:2006, Firm and Level Ground, 1.25 Stability and 500 mm Load Center)2150.0 kg

Rated Operating Load at Full Turn, Forks (Firm and Level Ground, 1.25 Stability and 500 mm Load Center, Transport 100 mm Above Ground)2740.0 kg

Straight Tipping Load, Bucket (ISO 14397-1:2007)4280.0 kg

Tire Size405/70 R18

maximum material densities general purpose

Bucket Weights - Horizontal Pin BOCE395.0 kg

Bucket Weights - Vertical Pin BOCE394.0 kg

Bucket Width1880.0 mm

Dump Height - Horizontal Pin Coupler2510.0 mm

Dump Height - SSL Coupler2395.0 mm

Maximum Material Density - Horizontal Pin Coupler1889 kg/m3

Maximum Material Density - SSL Coupler1755 kg/m3

Rated Capacity0.9 m3

BENEFITS AND FEATURES

WORK TOOLS

A range of buckets, forks and hydraulically powered work tools optimize machine ...

LEARN MORE

CUSTOMER SUPPORT

Unmatched dealer support and complete services provided by the world’s largest dealer ...

LEARN MORE

906H2 STANDARD EQUIPMENT

- transmission

Transmission, 20 km/h with heavy duty axles

Transmission inching function

Hydrostatic drive - loader

Hydraulic horizontal pin quick coupler or skid steer quick coupler

Proportional auxiliary hydraulic circuit

Loader arm float function

Connect under pressure hydraulic quick connector

Parallel lift Z-bar loader - engine

Cat C3.3B DIT EU Stage IIIA compliant

Cat C3.3B engine is EU Stage II and EPA Tier 2 emissions compliant

Two stage air cleaner with visual indicator

Cat extended life coolant

Lockable engine compartments

Easy quick release fuel filter/water separator

Engine oil drain valve

Closed circuit breather - electrical

Battery disconnect switch

Heavy duty battery, 12V

Engine cold starter aid

Alternator 80 A

Service point connector for electronic diagnostics (Electronic Technician™) - general

E-coat paint primer

Pressure test points

Recovery hitch and pin

Scheduled oil sampling S·O·S ports - operator environment

Radio-ready kit includes speakers (not in base cab)

Two doors

Cup holder

Sun visor

Heated rear window

ROPS and FOPS certified cab

Adjustable wrist rest

Retractable seat belt (2 inch)

Cabin light

Auxiliary power sockets

Coat hook

Pressurized cab

On board digital display cluster

Heater with window, side and feet vents

Sound suppression

Multifunction joystick with direction control

Proportional auxiliary control

Two external knock back mirrors

Warning indicators for major systems

Wiper/washer front and rear

Easy clean cab floor

Lockable storage box

Adjustable internal mirror

906H2 OPTIONS

- transmission

Transmission control upgrade

100% diff-lock on both axles, selectable on the move

Ride control

Speeder, 35 km/h with secondary steering - loader

High flow auxiliary hydraulics

Load check valves

Return to dig work tool positioner - engine

Engine block heater 120V

Engine oil drain valve (non spill eco drain) - electrical

Reverse alarm

Machine Security System (MSS)

Magnetic rotating beacon

Work tool wiring harness

Working lights, two front and two rear - general

Custom color

Rear light guards

Heavy duty coupler guard

Tire options including heavy duty tires - fluids

Biodegradeable hydraulic oil

Cat extended life coolant (-50° C) - operator environment

Air conditioning

Retractable seat belt (3 inch)

Cat radio/CD/MP3/WMA/AUX

ROPS and FOPS certified canopy

Base cab

Comfort and deluxe cabs

Mechanical joystick

Radio-ready kit for base cab (wiring, speakers, aerial and grille)

Rear blind - work tools

For all work tools and standard/high flow options (consult your Cat dealer)

For a summary of available cab options please refer to Cab Features.

MOTEUR

Works in a wide range of applications.

BENEFITS AND FEATURES

Features This low cab machine provides access to more areas on site and applications allowing for low entry machines. It is designed with simplicity and cost effectiveness in mind while still delivering great all-round performance to work in a wide range of applications.

- 0.9 m3 operating capacity

- Low cost rental specification (option)

- Low height over cab

- 18" rim size

Modern interior, high quality, with an intuitive design.

BENEFITS AND FEATURES

Excellent Visibility Visibility to the worksite has been kept to an optimum with two fully glazed doors, front low-level glazing, excellent rear visibility and a clear view to the work tool through the loader arms.

Cab Comfort Two armrests and an adjustable wrist rest as standard, intuitively laid out controls, low effort joysticks and steering are some of the features which give maximum operator comfort.

Digital LED Display All models feature a red backlit machine status cluster, with speedometer, located conveniently within the operator’s line of sight.

Multi Function Joystick Contains Forward-Neutral-Reverse switch, travel speed selector, 3rd auxiliary hydraulics, diff‑lock and constant flow controls. A mechanical joystick option is available for the 906H2.

Cab Options With a variety of options it is easy to customize the cab to meet your requirements. A choice of three cab trims and a canopy are available.

Cat Hystat power train delivers aggressive performance.

BENEFITS AND FEATURES

Two Speed Options The Cat hydrostatic driveline has two speed options, 20 km/h or 35 km/h. The 35 km/h speeder includes secondary steering. Both options feature smooth inching as standard, with optional travel speed, rimpull control and hand throttle (transmission control upgrade).

Disc Brakes The 35 km/h speeder version has hydraulically boosted oil immersed disc brakes fitted to both ends of the front axle. The 20 km/h version has a hydraulically actuated dry disc brake, both offering smooth and effective braking. The braking is applied through all four wheels.

Diff-lock The Cat Compact Wheel Loaders offer 100% diff-lock, in both axles as an option throughout the range. Diff-lock can be easily engaged on the move to allow travel over poor underfoot conditions.

Chassis Oscillation Oscillating chassis helps assure four wheel ground contact for optimum traction and stability.

Ride Control The ride control system further enhances the already smooth road handling of the machine, resulting in increased operator comfort and higher productivity. It is suited for extreme applications where operators need to maintain bucket load material and have a smooth ride. There are three modes available: auto, on and off. Recommended for use with the 35 km/h speeder option.

Making the Compact Wheel Loader even more versatile.

BENEFITS AND FEATURES

Horizontal Pin Coupler This quick coupler will pick up the new range of Cat Compact Wheel Loader work tools. The coupler along with the profiled loader arms have been designed to give maximum visibility to the work tool. A simple joystick function allows for easy engagement and disengagement of the locking pins.

Skid Steer Loader Coupler The universal skid steer loader coupler allows the use of many Cat Skid Steer Loader work tools. Using either the standard or high flow hydraulic option, this coupler allows the H2 Series Compact Wheel Loaders to integrate into a skid steer loader fleet.

The ideal linkage for Compact Wheel Loaders.

BENEFITS AND FEATURES

Z-bar Design Cat Compact Wheel Loaders make use of the high performance Z-bar loader design which has been optimized for strength, visibility and versatile attachment usage. The Z-bar linkage gives the operator a clear view to the work tool and excellent dump clearance while maintaining good cycle times and parallel lift.

A range of buckets, forks and hydraulically powered work tools optimize machine performance.

BENEFITS AND FEATURES

Wide Range of Work Tools To maximize machine utilization, Cat work tools are designed to get the best out of the machine and deliver excellent value through high productivity and long life. The new H2 Series Compact Wheel Loaders can now pick up even more work tools with the addition of a choice of couplers.

Work Tools for Cat Horizontal Pin Coupler The Cat Compact Wheel Loader offers a comprehensive range of buckets to suit any environment and specific customer needs. The buckets have been designed and engineered to endure the high breakout forces of the H2 Series Compact Wheel Loader. The Cat fork carriage has been designed to increase visibility to the forks, allowing the operator to work much more efficiently and safely, without compromising durability. Various fork tine lengths are available.

Work Tools for Cat Skid Steer Loader Coupler This coupler allows the use of Cat Skid Steer Loader work tools. Caterpillar recommends the following options when choosing the Cat Skid Steer Loader coupler:

- Return to dig work tool positioner

- Work tool wiring harness

- Transmission control upgrade

- High flow auxiliary hydraulics for high flow work tools

Auxiliary Lines and Connectors The auxiliary lines and connectors are fitted as standard, meaning the Cat Compact Wheel Loader comes ready to work. For a complete list of available work tools please consult your local Cat dealer.

Quality within, quality throughout.

BENEFITS AND FEATURES

E-Coat Protection Cat Compact Wheel Loaders undergo an extensive 24-Stage ‘E-Coat’ process. Zinc based electroplated undercoat and polyurethane topcoat provides unmatched corrosion resistant properties.

Heavy Duty Axles The H2 Series Compact Wheel Loaders are fitted with heavy duty axles, with outboard planetary reduction gears.

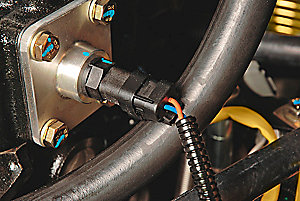

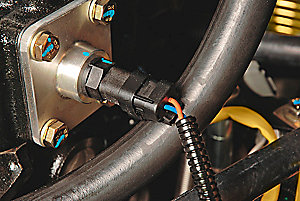

Wiring With heavy-duty braided wiring, Cat Compact Wheel Loaders offer great electrical durability. The water resistant sealed connectors prevent dust and moisture interfering with the electrics. Multicolored and numbered wiring is used for easy component identification.

Durable Design Durability has been designed into the machine by offering protection to features such as the rear lights, loader arm and coupler greasing points.

Quality Throughout High quality solid plastics, well-fitted rubber moldings make up the foundation of the H2 Series cab. Robust IP67 standard switches are used throughout, ensuring long life of components.

Unmatched dealer support and complete services provided by the world’s largest dealer network.

BENEFITS AND FEATURES

Your Cat dealer is ready to assist you with your purchase decision and everything after.

- Make comparisons of machines, with estimates of component life, preventative maintenance and cost of production.

- Financing packages are flexible to meet your needs.

- Your Cat dealer can evaluate the cost to repair, rebuild and replace your machine, so you can make the right choice.

- A worldwide computer network enables the dealer parts counter to locate nearly all parts.

- For more information on Cat products, dealer services and industry solutions, visit us at www.cat.com.

Easy access to service points for routine maintenance.

BENEFITS AND FEATURES

Conveniently located service points make maintenance easier.

- All routine maintenance points can be accessed safely from ground level

- S·O·S valves for preventative maintenance

- Ecological drains for all fluids, with on-board connector hoses

- Electronic Technician™ plug in port for advanced diagnostics

- Ground level access to filters for easy servicing

- Color coded and numbered wiring for easy component identification

- Oil cooler pack can be hinged open for easy cleaning

- A two stage air cleaner including a secondary element and a visual indicator for better service life

- Battery disconnect switch for safe servicing