CL215 – LOAD HAUL DUMP

The CL215 is the 15 tonne (16.53 ton) heavy-lift LHD and utility vehicle in the Cat range. Like the CL210, it can be used as a shield mover in combination with the SH150 trailer, allowing for the LHD to become a true utility vehicle with multifunction capabilities.

SPECIFICATIONS

Height2056 mm/80.9 in (and above)

Load Capacity15 tonnes/16.5 tons (max)

Power TypeDiesel

BENEFITS AND FEATURES

high reliability low cost

To ensure low life-cycle costs and high availability, all vehicles use tried-and-tested, ...

LEARN MORE

multipurpose

The Rapid Attach System (RAS) allows a range of accessories to be fitted, thus enhancing ...

LEARN MORE

operator safety and comfort

The cockpit design features ergonomic, intuitive controls and optimum visibility and ...

LEARN MOREspecifications

Height2056 mm/80.9 in (and above)

Load Capacity15 tonnes/16.5 tons (max)

Power TypeDiesel

axles standard

Front AxleFixed

Rear AxleTrunnion Mount

TypeOutboard Planetary

oscillation

Degrees Up and Down from Horizon7.5 Degree

vehicle speeds

1st Gear3.1 km/h

2nd Gear7.4 km/h

3rd Gear13.0 km/h

4th Gear23.0 km/h

engine

Cooling FanHydraulic Driven Fan

Cooling SystemWater Based Radiator

Displacement7.2 L

Engine Make/ModelCat 3126

Maximum Power172 kW (230 hp) @ 2,200 rpm

Maximum Torque720 N·m (531 lb-ft) @ 1,400 rpm

TypeDiesel, Turbocharged, 4 Cycle

start system

Starter Motor TypeAir Turbine Type

articulation

Degrees of Turn Either Side43 Degree

capacities

Bucket Payload12000.0 kg

Maximum Braked Trailer MassConsult Caterpillar

Maximum Un-braked Trailer Mass15000.0 kg

RAS Belt Reeler12000.0 kg

RAS Fixed Jib Maximum Payload10000.0 kg

RAS Forks, Maximum Payload15000.0 kg

RAS Slewing Jib, Maximum Payload8000.0 kg

standard ejector bucket

Heaped Capacity (SAE)4.5 m3

Struck Capacity3.5 m3

service capacities

Axle Oil (Each)71.0 L

Engine Cooling System Water72.0 L

Engine Crankcase Oil (with Filter)22.0 L

Fuel Tank300.0 L

Hydraulic Tank300.0 L

Main Air Receiver80.0 L

Transmission/Converter Oil40.0 L

Water Make Up Tank450.0 L

pneumatic system

Air Flow0.340 m3/min (12 ft3/min) @ 1,500 rpm

Air Receiver Volume80.0 L

Compressor TypePiston Engine Gear Driven

Governed Pressure800.0 kPa

Relief Pressure830.0 kPa

seating driver

TypeCross-seated

electrical system

PolarityFloating Chassis

TypeApproved Flameproof

Voltage12.0 volts

lights

Number/Location2 Front, 2 Rear; Approved Flameproof

alternator

DriveHydraulic

TypeApproved Flameproof

wheels

Make/Model5 Pieces (Heavy Duty)

tires – standard

Inflation MediaAir

Inflation Pressure – Front760.0 kPa

Inflation Pressure – Rear760.0 kPa

Ply RatingRadial

Size20.5 × R25

TypeXKA Tires

canopy

ROPS/FOPSOptional

Type Protective DeviceMDG1

grade ability

Front to Rear1:4

Side to Side1:8

Side to Side (Empty)1:4

weight

Maximum Laden44000.0 kg

Operating with Bucket Only29000.0 kg

Operating without Bucket26500.0 kg

intake air cleaner

Intake Flame TrapSpiral Wound Type

Type/MakeDry Dual Element/Caterpillar

exhaust conditioner

AftertreatmentCatalytic Exhaust Purifier

Exhaust FilterReplaceable Element Except China

Exhaust Flame TrapReplaceable China and RSA

MakeCaterpillar

TypeFlameproof Wet

transmission

Speeds, Forward and Reverse4

TypePower Shift with Forward/Reverse

hydraulic filtration

Bucket SystemReturn 10 Micron; Replaceable with Bypass

Steer/Brake SystemPressure 10 Micron; Replaceable with Bypass

shutdown system

Optional Shutdowns• High Methane • Low Hydraulic Oil • Exhaust Scrubber Temperature

Standard Shutdowns• Low Engine Oil Pressure • Exhaust Temperature • Engine Coolant Level • Engine Coolant Temperature

Standard Shutdowns (cont'd.)• Turbo Temperature • Scrubber Level 1 • Scrubber Level 2

System TypeDCS Electronic; Intrinsically Safe Approved

engine speeds

Governed2600.0 RPM

High Idle2700.0 RPM

Low Idle800.0 RPM

fuel consumption

At Full Power37.5 L/hr

Average Mine Duty8-30 L/hr (2.1-7.9 gal/hr)

BENEFITS AND FEATURES

HIGH RELIABILITY, LOW COST

To ensure low life-cycle costs and high availability, all vehicles use tried-and-tested, ...

LEARN MORE

MULTIPURPOSE

The Rapid Attach System (RAS) allows a range of accessories to be fitted, thus enhancing ...

LEARN MORE

OPERATOR SAFETY AND COMFORT

The cockpit design features ergonomic, intuitive controls and optimum visibility and ...

LEARN MORE

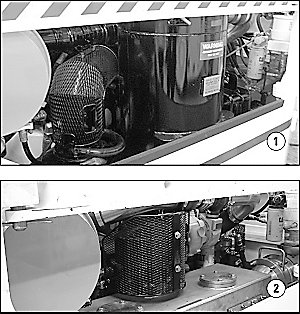

ENGINES

All machines can be supplied with various diesel engine packages suited to the ...

LEARN MORE

EXHAUST SYSTEMS

Caterpillar can offer the underground mining industry the choice of either a wet exhaust ...

LEARN MORE

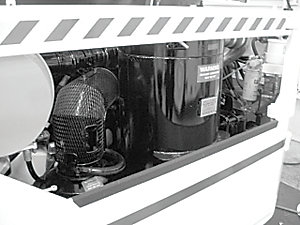

COOLING SYSTEMS

Caterpillar offers radiator units in either vertical or horizontal configurations.

LEARN MORE

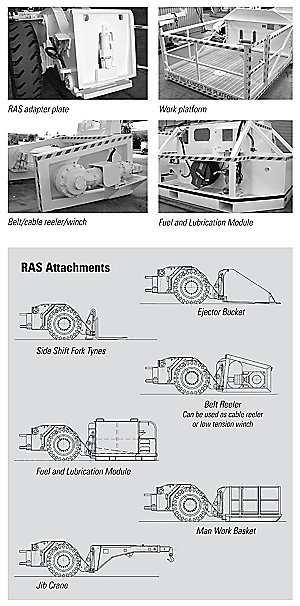

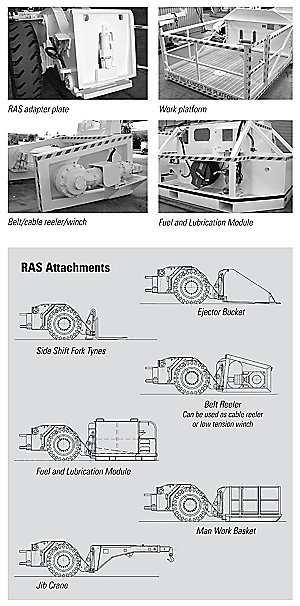

RAPID ATTACH SYSTEM (RAS)

The RAS system makes an accessory change a safe, one-man operation, allowing a broad ...

LEARN MORE

CL215 STANDARD EQUIPMENT

- • the cat cl215 comes standard with the rapid attachment system ras for rapid pick up and release of attachments

CL215 OPTIONS

- • filled tires – insert or foam

- • fire suppression system

- • 15 000 kg 33069 lb forks with side shift

- • 8000 kg 17636 lb slewing jib crane

- • elevating work platform

- • fuel and lubrication pod

- • concrete hopper attachment

- • alternative approved electrical components lights alternators hour meters etc

- • load indication gauge system

- • tow chains

- • auto lubrication system

- • 10 000 kg 22064 lb beltcable reeler

- • 55 m3 72 yd3 bucket

- • trailer towing adapter cht50

MOTEUR

To ensure low life-cycle costs and high availability, all vehicles use tried-and-tested, commercially available powertrain components that offer high reliability and availability with high fuel economy.

BENEFITS AND FEATURES

Components are of the highest possible quality and meet or exceed operational and design requirements. The use of reliable and powerful diesel engines ensures maximum power in a compact design.

Space is at a premium in underground roadways, so the vehicles are designed to be compact, with a minimal profile and roadway presence.

BENEFITS AND FEATURES

They are also designed to be cost-effective in operation and to meet the user’s need for the safest maximum possible capacity, speed and power.

The Rapid Attach System (RAS) allows a range of accessories to be fitted, thus enhancing the flexibility of the vehicles in operation.

BENEFITS AND FEATURES

RAS allows the use of accessories from forks and buckets to jib cranes and reelers, as well as many others.

Compliance to regional regulations and guidelines is achieved by using a variety of engine and exhaust conditioner packages.

BENEFITS AND FEATURES

Cat equipment is compliant to Australian Standard MDG guidelines, MSHA (USA), MA (China) and DGMS (India) legislative regulations for underground coal mining. Caterpillar also supplies diesel equipment for non-coal mining applications.

The cockpit design features ergonomic, intuitive controls and optimum visibility and safety. This means that operators already trained on one machine can quickly learn to use the others in the range.

BENEFITS AND FEATURES

All vehicles are compliant with current and anticipated future safety requirements, such as exhaust filtering, falling object protection and maximized visibility. Pilot hydraulic- and electronic-controlled vehicles are available with the option of dials and gauges or an LCD instrument cluster. Demanding working conditions require that the operator is comfortable for the entire shift, so suspension seats and restraint systems have been selected to assist in fatigue management and increase safety.

All machines can be supplied with various diesel engine packages suited to the customer’s requirements. Like all components, our engines are industry-recognized and accepted.

BENEFITS AND FEATURES

This means high quality, excellent availability and economy of spare parts, and, as a result, high service availability. A broad range of mechanical and electronic engine packages are available, allowing vehicles to be tailored to specific applications or to meet regulations.

Caterpillar can offer the underground mining industry the choice of either a wet exhaust scrubber system or a dry particulate filter system. Both the wet and dry exhaust scrubbers employ a particulate filtration system with an inline purifier and catalytic converter.

BENEFITS AND FEATURES

Caterpillar has designed a proprietary diesel exhaust solution to meet the highest emissions standards for the health and safety of personnel. The replaceable Cat particulate filter captures particulate matter, preventing its release into the mining atmosphere. A heat exchanger or wet bath scrubber is used to reduce exhaust-gas temperature and a catalytic converter reduces gaseous emissions. The exhaust system is monitored by the Cat DCS electronic shutdown system, which prevents the machine from being operated in unsafe conditions like low water levels or high exhaust system temperatures. Both dry and wet exhaust packages are approved for underground coal mine operation.

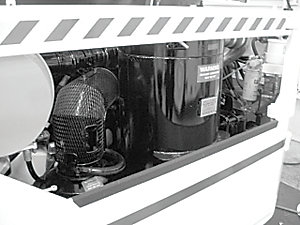

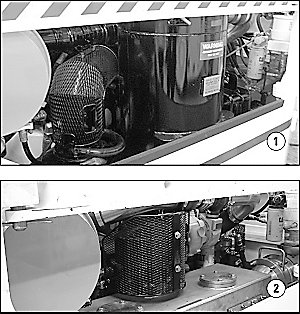

Caterpillar offers radiator units in either vertical or horizontal configurations.

BENEFITS AND FEATURES

The dry scrubber exhaust system features a dual independent cooling system with one for the exhaust system and another for the engine system, providing a balanced coolant flow through both systems. The wet-bath-exhaust-equipped machine has a single cooling system for the engine cooling and the exhaust gas is cooled by constant consumption from the exhaust scrubber reservoir.

The base specification LHD electrics consist of four flameproof lights powered by a flameproof Cat alternator and a DCS intrinsically safe engine monitoring and shutdown system.

BENEFITS AND FEATURES

There are a number of additional options available for explosion or non-explosion protected machines that include:

- LCD graphical display in flameproof enclosure

- Dimming and directional control of the lights

- Solenoid-operated valve banks with spool monitoring

- Electronic shift transmission

- 12 V or 24 V electrical system

- Reversing camera and display in flameproof enclosure

- Electronic joystick control of hydraulics

All Cat LHD machines can have their operation safety checks performed by the operator in minutes at the beginning of the shift.

BENEFITS AND FEATURES

To return a high service availability, the equipment design has been aimed towards reducing machine downtime during maintenance and servicing tasks.

The RAS system makes an accessory change a safe, one-man operation, allowing a broad range of accessories to be fitted in moments without removing the backing plate or the operator having to leave the cab.

BENEFITS AND FEATURES

A fifth-wheel trailer hitch can also be fitted so that the SH150 can be used for moving roof supports.

Do more job with one machine.

BENEFITS AND FEATURES

Range of Attachments

- Hydraulic side shift forks for pan transportation

- Ejector plate bucket for scoop operations

- Lube pod for miner support, diesel/battery fleet support

- Jib cranes for drive head motor replacement

- Work platform for pipe, cable or roof repair

- Reeler unit for belt/cable/AFC/BSL/Bretby

- QDS attachment – allows use of third-party accessories

SH150 Roof Support Trailer The SH150 roof support trailer turns your LHD into a high-speed shield hauler capable of carrying 50 tonnes (55.12 tons) and shields up to 2 m (6.56 ft) wide with an integrated hydraulic loading winch. The trailer is designed for moving roof supports and chocks. A hydraulic assist drive system can be fitted as an optional upgrade to support areas of inconsistent floor and roadway conditions for intermittent operation. A rated hydraulic winch is available for loading roof supports and two in-floor load positional cylinders can be used for assistance with unloading. With spring-applied hydraulic brakes and solid rubber wheels, the trailer is hydraulically lowered and raised for easy loading and unloading of transport. The trailer has a capacity of 30 000 or 50 000 kg (66,139 or 110,231 lb) and can carry a 2 m (6.56 ft) roof support. The SH150 can be towed by the CL210 and CL215.

General Purpose Trailer With a tare mass of 3 tonnes (3.31 tons), the general purpose trailer can carry loads of up to 7 tonnes (7.72 tons). With a simple ladder-frame design, the width of the trailer can be selected to suit mine drive heading sizes. The flat deck and gate railing system allow flexible loading and unloading from either side with forks or handling devices.

Conveyor Structure Module Fitting on top of a standard general purpose trailer, the conveyor structure module allows all components for a certain section of conveyor to be loaded and stored together. This modular approach not only speeds loading and unloading, but prevents damage to and loss of valuable components.