FH110 – FACE HAULER

Our flexible and maneuverable battery-powered face haulers are designed to maximize the payload capacity in a given seam height. They're equipped with the HiPac 10 VFD Drive System, which increases ground speeds, improves haulage cycle time and delivers more work per battery discharge. Operators are comfortably and safely enclosed in a thick steel envelope with a clear view front and back. Convenient operator's control stick and scoop-type controls enable productivity. And to change directions, operators simply turn their heads.

SPECIFICATIONS

Operating Height0.99-1.52 m (39-60 in)

Max. Carrying Capacity9 tonnes (10 tons) 15 m3 (530 ft3)

Power TypeBattery

BENEFITS AND FEATURES

major features

LEARN MORE

freedom of movement

Cableless face haulers have several advantages over cable-driven shuttle cars: They have ...

LEARN MORE

packed with power

Because of their superior productivity and flexibility, Caterpillar has focused on ...

LEARN MOREspecifications

Operating Height0.99-1.52 m (39-60 in)

Max. Carrying Capacity9 tonnes (10 tons) 15 m3 (530 ft3)

Power TypeBattery

Empty Weight37.2 tonnes

EngineN/A

Ground Clearance254 or 305 mm (10 or 12 in)

Load Discharge Time24.0 Seconds

Max. Tram Speed8.0 km/h

Overall Length (with tailgate)11.89 m

Overall Width3.66 m

PowerDual 26 kW (35 hp) DC motors

Wheel/Tires889 or 965 mm (35 or 38 in)

battery changer

TypeGround Level Battery Changer System

TypeNo battery stands are required.

TypeHydraulically operated integral system that includes 2 independent battery lift arms that work simultaneously during operation.

frame

TypeHeavy-duty, with bends utilized where applicable to reduce the number of indeterminate stresses introduced by welding.

handle manuals

TypesOne Linkone CD, which includes all above manuals in electronic format

TypesTwo parts manuals

TypesTwo battery maintenance charts

TypesTwo electrical troubleshooting guides

TypesTwo battery maintenance manuals

TypesTwo operation and preventive maintenance manuals

hydraulics and controls

ComponentsBattery tuned battery-lift shock absorption for ride comfort

ComponentsOpen Loop with gear pump hydraulic system

ComponentsHydraulic component design and placement for ease of service and/or maintenance and fewer hydraulic components and hoses

ComponentsBattery lift load-locking counterbalance valves for safety

wheelbase

Empty Weights – With 64-SS100-25 Battery31524.0 kg

Empty Weights – With 64-SS85-25 Battery30844.0 kg

Empty Weights – Without Battery23995.0 kg

turning radius

Discharge Time24 seconds

Steering Articulation120 degrees total

Terrain Compensation Articulation(+) 15 degree/(–) 10 degree

Tram Speed (Speed will vary depending on floor conditions)0-8.04 km/h (0-5 mph)

dimensions approximate

Frame Height914-990 mm (36-39 in)

Ground Clearance – with 35" Tires194.0 mm

Inside Turning Radius3.6 m

Minimum Canopy Height – with 35" Tires1092.0 mm

Minimum Entry Width4.62 m

Operating Height1066-1524 mm (42-60 in)

Outside Turning Radius7.51 m

Overall Length11850.0 mm

Trailer3302.0 mm

Trailer Frame Height – with 35" Tires914.0 mm

Trailer Height – with 35" Tires at Top of False Bottom954.0 mm

Width – Extended Deck3395.0 mm

operator’s compartment

FeaturesManual breaker lever reset

FeaturesFull height back and head protection

FeaturesHeavy-duty, adjustable, ergonomically designed operator’s seat

FeaturesErgonomically designed control stick, for one-hand control of face hauler

FeaturesRight-foot-operated accelerator switch pedal

FeaturesDual panic tape switches that de-energize electrical system and apply automatic brake

FeaturesWarning gong

FeaturesLeft-handed mechanical steering handle

FeaturesRight-hand vertical articulation handle (terrain compensation)

FeaturesRight hand battery changer handle

FeaturesRight-hand battery lock/unlock handle

FeaturesRight-handle battery float handle (independently located separate from valve bank)

FeaturesLeft-foot brake pedal

FeaturesEasily visible glycerin-filled gauges

FeaturesSide egress, access

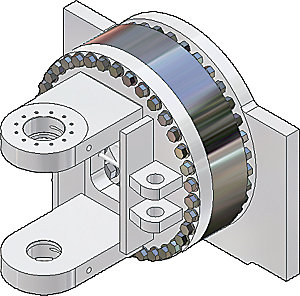

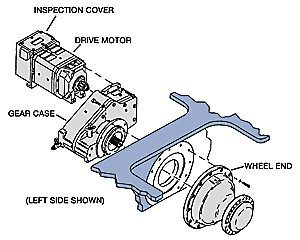

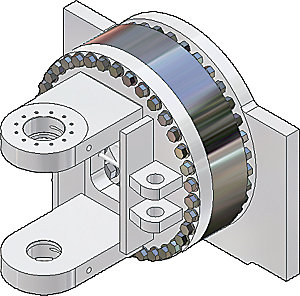

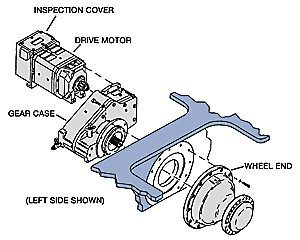

drive train

DesignTwo proprietary design

DesignDouble-reduction parallel primary reducers equipped with integral multiple wet disc brakes and axle shaft

DesignMounted to a proprietary design planetary wheel end

general data

Payload Capacity9.0 tonnes

Power TypeBattery

brakes

Automatic BrakeSpring-applied, hydraulic-released braking system controlled by electrical/hydraulic solenoid

Automatic BrakeEquipped with totally enclosed multiple wet disc brake in each drive unit

Automatic BrakeEquipped with manual hand pump brake release and glycerin-filled pressure monitoring gauge

ServiceTwo (2) hydraulic actuated, multiple wet disc brakes

center section

TypeHeavy-duty, dual-articulation joint, welded steel construction with steel pivot pins

TypeAxial load rating of 261 269 kg (576,000 lb)

TypeHorizontal self-aligning pivot thrust bearings on the articulation and ball bearing on secondary articulation

design gross vehicle weight

Cubic Feet Capacity: (Maximum Payload – Calculated) – Heaped with No Sideboards12.34 m3

Cubic Feet Capacity: (Maximum Payload – Calculated) – Struck Capacity6.25 m3

hydraulics

Battery Changer CylinderTwo (2) double-acting cylinders with 63.5 mm (2.5 in) shock-absorption relief system.

PumpMain hydraulic system, gear type pump directly splined to pump motor at 16 054 kPa (2,300 psi)

PumpMonitored by a glycerin-filled main system pressure gauge

Pump MotorAlternating current motor: MSHA totally enclosed, explosion-proof, non-ventilated cooling, and foot-mounted

Pump MotorMine duty laminated frame

Reservoir189.27 L (50 gal) capacity reservoir equipped with breather and removable suction strainer.

Steering CylinderTwo (2) double-acting cylinders with 63.5 mm (2.5 in) forged rods. Equipped with integrated shock-absorption relief system.

Valve BankFive-section parallel type equipped with glycerin-filled pressure-monitoring gauge

Valve BankFunctions: • Eject/Retract • Vertical Articulation (Terrain Compensation) • Battery Lift (Changer) • P.T.O. • Steering

electric drive train

ComponentsOperator interface diagnostic and information display

ComponentsVariable-frequency traction drive

ComponentsLead acid battery DC power source

Components36 kW (48 hp) inverter duty AC inductance pump motor

ComponentsControl system with operator interface accelerator and operator interface control handle

Components56 kW (75 hp) AC inductance traction motor

BENEFITS AND FEATURES

MAJOR FEATURES

LEARN MORE

FREEDOM OF MOVEMENT

Cableless face haulers have several advantages over cable-driven shuttle cars: They have ...

LEARN MORE

PACKED WITH POWER

Because of their superior productivity and flexibility, Caterpillar has focused on ...

LEARN MORE

THE CLEAN AIR ACT

Cat® battery-powered face haulers do not burden the mine environment with emissions or ...

LEARN MORE

STATE-OF-THE-ART DRIVE ...

Since their introduction, Cat face haulers have led the industry with state-of-the-art ...

LEARN MORE

ERGONOMICALLY-DESIGNED ...

The operator’s compartment provides a safe and comfortable working environment. Clear ...

LEARN MORE

HEAVY-DUTY BALL BEARING ...

Cat face haulers offer the strongest center sections in the market and superior ...

LEARN MORE

PROVEN MINE DUTY DRIVETRAIN

Cat face haulers feature dual 56 kW (75 hp) AC 3 phase motors.

LEARN MORE

ONE POWERFUL PACKAGE

The Cat East Penn battery is built for the long run, providing the lowest cost of ...

LEARN MOREFH110 STANDARD EQUIPMENT

- • each design maximizes payloads in a given seam height

- • true tracking geometry improves maneuverability and decreases haulage cycle time

- • the cat hipac 10 vfd drive system increases empty and loaded ground speed improving haulage cycle time delivering more work per battery charge and providing a machine management system

- • no trailing cables means unlimited flexibility when traversing the mine and getting to and from the face

- • operators are comfortably and safely enclosed in a thick steel compartment with clear visibility to front and rear

- • face haulers are powered by the east penn deka battery which provides the highest level of performance and productivity

FH110 OPTIONS

- • battery plugschange cablesreceptacles

- • chargers

- • batteries motor speed cutback

- • controller protective guarding

- • pump motor protective guarding

- • wheel guarding

- • canopy extension adapters

- • powerfill

MOTEUR

BENEFITS AND FEATURES

• Electric Drive Control System

• Payload Capacity

• Simple Hydraulics

• True Tracking

• Tire and Battery Options

Cableless face haulers have several advantages over cable-driven shuttle cars: They have greater freedom of movement as there are no trailing cables, and travel is not restricted by cable length, typically 200 meters or less.

BENEFITS AND FEATURES

They can travel and unload faster than shuttle cars, carry a 15–20% greater payload and operate in narrow roadways with tighter turns.

Because of their superior productivity and flexibility, Caterpillar has focused on battery- and diesel-powered face haulers.

BENEFITS AND FEATURES

Each offers distinct advantages. All machines combine compact power, capacity and maneuverability with long-term availability and efficiency.

Cat® battery-powered face haulers do not burden the mine environment with emissions or heat. Due to infinitely variable power control, they are the ideal vehicle for conditions where heat, emissions and noise would impact work and where a flexible vehicle is needed.

BENEFITS AND FEATURES

As the world leader in battery-powered vehicles for the underground mining industry, we take pride in providing the world’s most advanced battery-powered face haulers. Innovative solutions in power control and transmission contribute to making maximum use of battery power.

Since their introduction, Cat face haulers have led the industry with state-of-the-art drive technology. The latest Caterpillar innovation is the HiPAC 10 VFD control system, which drives the motive traction and hydraulic systems, and provides the operator with machine management information.

BENEFITS AND FEATURES

The HiPAC 10 is a DC-to-AC variable-frequency inverter control that drives high-performance AC electric motors, which have superior speed-torque characteristics. It is up to 14% more efficient than traditional DC motors. This means higher loaded tram speeds, more responsive hydraulic functions, and more material hauled per battery charge. The HiPAC 10-machine management system speeds fault diagnosis, allowing rapid repairs and maximizing uptime. The new user interface can display data such as drive unit temperatures and distance traveled per battery charge.

The operator’s compartment provides a safe and comfortable working environment. Clear lines of sight are provided to the front, back, and sides.

BENEFITS AND FEATURES

The ergonomic control stick gives the operator intuitive one-hand control of tram direction, lights, parking brake, four-wheel assist and pump motor start. The operator’s display has been upgraded to show all operating parameters at a glance, with provision for fault analysis and data logging.

Ruggedness and durability are the key elements in the life of a battery-powered hauler. Through the use of Finite Element Analysis, each Cat frame is designed for maximum strength without adding power-robbing weight.

BENEFITS AND FEATURES

In the new FH120, the driving wheels are an equal distance from the articulation pivot, allowing precision true tracking of front and rear wheels. The resulting elimination of wheel scuff increases tire life and improves efficiency. It also enhances maneuverability, as the hopper section will fit within the same area as the tractor section.

Cat face haulers offer the strongest center sections in the market and superior oscillation in tough conditions. The rolling-element oscillation bearing ensures smooth ground-contour following of driven wheels for maximum traction.

BENEFITS AND FEATURES

The connecting plates for the bearing are manufactured from high-strength ASTM A514 steel, ensuring a strong and reliable articulation joint. The FH120 face hauler boasts a 240% increase in bolt moment capacity.

Cat face haulers feature dual 56 kW (75 hp) AC 3 phase motors.

BENEFITS AND FEATURES

In addition to improved performance and power efficiency, AC motors eliminate the need for DC commutators and brush riggings, cutting operating costs and downtime. Two proprietary double reduction, parallel gear reducers equipped with multiple wet disc brakes connect to the planetary wheel ends.

The Cat East Penn battery is built for the long run, providing the lowest cost of ownership in the industry.

BENEFITS AND FEATURES

Specially formulated premium-grade lead oxide is used in the flat plate design and each plate is individually formed prior to cell assembly, which assures uniform performance and maximization of amp-hour capacity. State-of-the-art computerized equipment is utilized in every phase of the production process, and stringent quality checks are made on each battery to ensure the highest level of performance.