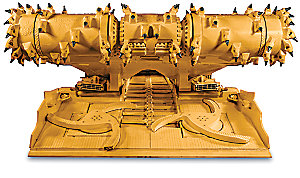

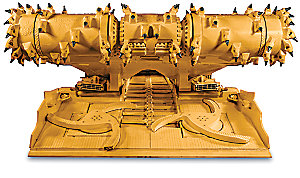

CM220 – CONTINUOUS MINER

For thin- to mid-seams we have the CM200 Series – from the thin-seam CM210 with a minimum cutting height of 0.76 m (30 in) to the mid-seam CM240 for seams of up to 3.4 m (134 in).

SPECIFICATIONS

Mining Range0.86-2.39 m (34-94 in)

Weight52.2 tonnes (115,000 lb)

Total Power522.0 kW

BENEFITS AND FEATURES

longer overhaul interval

In addition to offering features that deliver superior performance, Cat continuous miners ...

LEARN MORE

efficient cuts

Infinitely variable tram control allows precise control of steering, speed and traction ...

LEARN MORE

ease of operation

Caterpillar offers a Machine Control Unit designed to operate the entire Cat continuous ...

LEARN MOREspecifications

Mining Range0.86-2.39 m (34-94 in)

Weight52.2 tonnes (115,000 lb)

Total Power522.0 kW

BENEFITS AND FEATURES

LONGER OVERHAUL INTERVAL

In addition to offering features that deliver superior performance, Cat continuous miners ...

LEARN MORE

EFFICIENT CUTS

Infinitely variable tram control allows precise control of steering, speed and traction ...

LEARN MORE

EASE OF OPERATION

Caterpillar offers a Machine Control Unit designed to operate the entire Cat continuous ...

LEARN MORE

HIGH AVAILABILITY, LOW ...

The dimensioning of components and structural elements – such as motors, pumps, ...

LEARN MORE

EASE OF MAINTENANCE

Cat continuous miners are designed to facilitate maintenance, which in turn cuts costs ...

LEARN MORE

COMMONALITY OF PARTS

The CM220, CM230 and CM240 have common components such as gathering head gearboxes, ...

LEARN MORE

LOW OVERHAUL FREQUENCY

The overhaul interval is maximized by various measures to reduce wear and tear. All major ...

LEARN MORECM220 STANDARD EQUIPMENT

- • heavy main frame for rigidity and stability

- • independent tramming for maneuverability

- • wide conveyor for maximum loading rates

- • wide crawlers for maximum penetration and low ground pressure

- • radio remote with self diagnostics available

- • easy access and low maintenance

MOTEUR

In addition to offering features that deliver superior performance, Cat continuous miners offer a whole range of engineering features that contribute to long, reliable service between overhauls.

BENEFITS AND FEATURES

This means greater productivity and higher tonnage between rebuilds.

Infinitely variable tram control allows precise control of steering, speed and traction with independent control of the two sides. This high maneuverability allows faster positioning and optimum cutting, increasing productivity.

BENEFITS AND FEATURES

Cat continuous miners also have a lift kit that allows cutting height changes to be made within 3 hours. This rapid change is made possible by pin-on wire runners. Our competitors’ machines require welding and cannot compete with this speed.

Cat continuous miners use a 75 mm steel plate for the main frame – 50% thicker than competitors.

BENEFITS AND FEATURES

The heavier, more rigid frame allows a better cutting rate when sumping at the top of the seam and ripping to the bottom.

Caterpillar offers a Machine Control Unit designed to operate the entire Cat continuous miner. Based on a mine-duty PLC, this drive and control system combines maximized coal production and operator safety with minimum downtime.

BENEFITS AND FEATURES

As traction motors are controlled by a microprocessor-based system, the design minimizes the connection points that are the major cause of downtime. It provides data logging, fast diagnostics and enhanced troubleshooting capability.The optional ergonomic graphics display provides easy access to visualization, parameters, logs and help. Screens can be accessed via the transmitter and parameter changes can be made. The unit allows three modes of control: wireless for normal operation, umbilical and a mode for troubleshooting.

Caterpillar has ongoing development aimed at providing mining operations with reliable controls to the level of complexity that fits their needs.

BENEFITS AND FEATURES

The system can be tailored to meet the needs of an operation with a combination or total of:

- AC VFD (Variable Frequency Drive) or DC Drive Options

- Integrated electronic overloads

- Color graphic diagnostic options

- Data logging

- Smart Hydraulic System

The dimensioning of components and structural elements – such as motors, pumps, clevises and pivots – and their location and packaging ensure ease of maintenance, increase machine availability and reduce operating costs. Cat continuous miners are built to last.

BENEFITS AND FEATURES

For example, the Cat clevis is 113 mm, compared to 100 mm for our major competitor, and pin diameter is 194 mm compared to 100 mm. The rugged design of Cat continuous miners ensures long maintenance intervals and higher tonnage between rebuilds.

Cat continuous miners are designed to facilitate maintenance, which in turn cuts costs and increases availability and productivity. Unlike our major competitor, the cutter head gearcases on Cat machines are independent.

BENEFITS AND FEATURES

So if there is a failure on one side, only one half of the cutter head has to be replaced as opposed to changing the whole head. Tram cases can be repaired on machine without having to pull the tram case off the miner, resulting in considerable time and cost savings. The Centrifugal Loading Arm (CLA) has abrasion-resistant replaceable tips, allowing quick and easy refurbishment.

The CM220, CM230 and CM240 have common components such as gathering head gearboxes, conveyor motors, tram motors, tram gearboxes, electrical boxes, radio control system, hydraulic pump, pump motor and crawler chain assemblies. The major common components of the CM330, CM340, CM345 and CM430 are the gathering head gearboxes, conveyor motors, tram motors, tram gearboxes, radio control system, hydraulic pump, pump motor, cutting head gearbox and crawler chain assemblies.

BENEFITS AND FEATURES

This commonality of parts has numerous advantages:

- Lower cost of inventory and higher parts availability

- Faster replacement

- Trained technicians can fix any machine in series

- Flexibility: for example, the CM230 can be converted into a CM220

Motors are designed for heavy-duty 50 Hz operation so as not to compromise power, speed or production. Overheating and failure of these powerful motors is prevented by electronic motor overload protection.

BENEFITS AND FEATURES

Cutter motors are protected by a clutch and have no torque shafts, whereas gathering motors and dual-reduction gathering gear cases are protected by quill shafts which, like a torsional spring, twist along their length. Cooling system monitoring ensures that the proper flow and pressure are available to cool the motor and electrical system.

The robust gears are made from carburized high-alloy steel with ground teeth for accuracy and quiet operation. The replaceable cutter head input gear cases allow quick and economical replacement of the components most susceptible to failure due to inadequate lubrication.

BENEFITS AND FEATURES

The long-life double planetary tram gear case has separately changeable planetaries and sprockets incorporating improved torric seal protection. The design of the high-speed gearing makes troublesome bevel gearing unnecessary. Helical input gears and spiral bevel gears maximize cutter gearbox life.

The overhaul interval is maximized by various measures to reduce wear and tear. All major wear areas – including spade, conveyor and cutter gear case webs – have long-life 13 mm Chrome Carbide Overlay (CCO) liners.

BENEFITS AND FEATURES

Extra-large cutter boom pin and bush increase load and fatigue capacity, while traction liners are extra-thick for extended life. Cabling and hydraulic hosing are integrated for improved protection. Spigoted and/or keyed mounting of cutter motors, traction motors and traction gear cases isolate mounting bolts from the load.