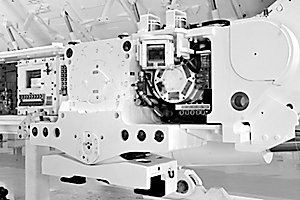

EL2000 - SHEARER

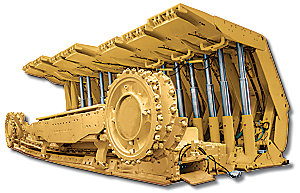

The EL2000 incorporates all the features and benefits that have been established with the Cat shearer range in a compact, rugged machine designed to meet the demands of high productivity in low- to medium-seam applications from 1.80 to 4.50 m (70 to 177 in.). High installed power is a feature of the EL2000 shearer, with up to 750 kW (1,200 hp) in a compact design. The haulage system is tailored to the needs of high-productivity medium-seam applications with up to 125 kW (200 hp) AC drives.

SPECIFICATIONS

Typical Machine Length14.1 m

Installed Power1780.0 kW

Haulage SystemAC inverter drive

BENEFITS AND FEATURES

shear performance

With high-powered ranging arms and haulage units, Cat shearers cut and load up to 5000 ...

LEARN MORE

key improvements

Cat shearers incorporate numerous new features and benefits. These are presented in the ...

LEARN MORE

mainframe made for muscle

The unique mainframe of the Cat shearer is one of its key features. The fabricated ...

LEARN MOREspecifications

Typical Machine Length14.1 m

Installed Power1780.0 kW

Haulage SystemAC inverter drive

Applicable Minimum Pan Width1032.0 mm

Available Cutting Power2 × 500 kW; 2 × 620 kW; 2 × 750 kW

Available Haulage Motors2 × 125 kW (2 × 168 hp)

Body Height600.0 mm

Cutting Drum Diameter1600-2500 mm (63-98.5 in)

Haulage PullUp to 945 kN (Up to 107 tons)

Haulage SpeedUp to 30.1 m/min (Up to 98.5 ft/min)

Height Range1.80-4.50 m (71-177 in)

Machine WeightApprox. 70 tonnes (Approx. 77 tons)

Operating Voltages3300V; 4160V

Pump Motor30.0 kW

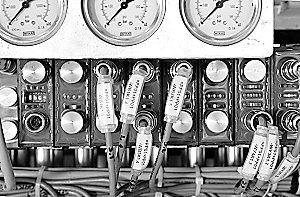

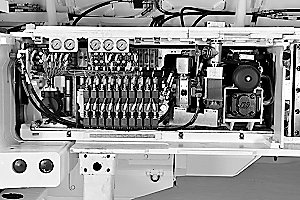

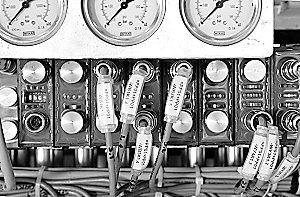

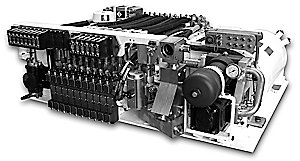

electrical control box ecb2

TypeThis flameproof module contains the majority of the shearer electrical control and power distribution components.

TypeHigh current carrying capacity of 400 amps and can accommodate trailing cables up to 185 mm2 (2.9 in2).

TypeAll internal chassis can be ‘bench built,’ tested and stored.

TypeThis unit also contains high voltage (HV) fuses, earth leakage and a visible disconnect.

TypeAn extremely powerful PMC Evo-S control system with state-of-the-art Ethernet communication and backup functionality.

TypeThis unit contains cutter motor contactors, circuit breakers, control transformer and current monitoring.

TypeBox contains various low voltage (LV) circuit breakers which can be reset through the flame proof (FLP) cover, reducing downtime

health monitoring

TypeThis system monitors oil levels and temperatures, flows, pressures and vibration.

TypeA comprehensive health monitoring system is available.

dimensions approximate midlow

AFC Pan Width - Maximum1342.0 mm

AFC Pan Width - Minimum1032.0 mm

Clearance from Drum to AFC Toeplate300.0 mm

Cutting Heights - Maximum4135.0 mm

Cutting Heights - Minimum1900.0 mm

Diameter of Shearer Cutting Drum1900.0 mm

Distance between Drums with Arms Horizontal14155.0 mm

Distance between Ranging Arm Hinge Points8525.0 mm

Distance between Trapping Shoe Centers6056.0 mm

Height to Top of Machine Main Body1495.0 mm

Machine Height over Main Body1495.0 mm

Maximum Cutting Drum Overall Width1150.0 mm

Ranging Arm Cutting Drum Diameter1900.0 mm

Ranging Arm Length (Hinge to Drum)2815.0 mm

Shearer Drum Undercut of Floor718.0 mm

Vertical Tunnel Clearance649.0 mm

machine @ 50 hz

Available Cutting Power2 x 500 kW (2 x 671 hp); 2 x 620 kW (2 x 831 hp); 2 x 750 kW (2 x 1,006 hp)

Body Height600.0 mm

Cutting Drum Diameter1600-2500 mm (63-98.5 in)

Cutting Drum Speed32.8, 37.4 and 45.2 rpm

Haulage Motor2 x 125 kW (2 x 168 hp)

Haulage PullUp to 945 kN (96 tons)

Haulage SpeedUp to 30.1 m/min (98.8 ft/min)

Haulage SystemAC inverter drive

Installed PowerUp to 1780 kW (Up to 2,387 hp)

Machine Weight (approximate)70.0 tonnes

Minimum Pan Width1032.0 mm

Operating Voltage3300.0 volts

Pump Motor30.0 kW

Seam Range1.8-4.5 m (71-177 in)

Typical Machine Length (drum centers)14155.0 mm

water material

TypeAll hose assemblies are to ISO 6805 and proof tested to EN ISO 1402.

TypeThis shearer is available with onboard filtration, dust suppression spray bars, shearer clearers and ranging arm spray rings.

TypeThe hoses are assembled to Hose Assembly Standard DIN20066:201-10.

haulage unit hu125

Maximum Machine Speed28.56 m/min

Pull at Maximum Speed472.75 kN/106,278 lbf (48.40 tonnes/53.35 tons)

Speed at Maximum Pull14.28 m/min

Total Machine Pull945.51 kN/212,559 lbf (96.80 tonnes/106.70 tons)

TypeQuillshaft transmission protection

TypeIntegral water cooling @ 9 L/min (2 gal/min)

TypeIntegral monitoring transducers

TypeMaximum oil capacity of 25 L (7 gal)

TypeTransmission reduction of 137:1

TypeMaximum power rating 125 kW (168 hp)

TypeThis unit has a haulage motor rating of 125 kW (168 hp)

ranging arm ra750

TypeTransmission rating of 750 kW @ 37.4 rpm and above

TypeMaximum drum diameter of 2500 mm (98 in)

TypeSquare drum hub (440 mm [17.3 in] across flats)

TypeA robust cowl drive mechanism is also available on this model

TypeOnline vibration monitoring with VibraGuard

TypeAvailable cutter motors - 500 kW, 620 kW and 750 kW, @ 50 Hz (800 hp, 1,000 hp and 1,200 hp, @ 60 Hz)

TypeChoice of drum speeds

TypeComplete with 32 mm (1.3 in) bore, through shaft PFF/PBF wet cutting

TypeIntegral monitoring transducers

TypeQuillshaft transmission protection

TypeMaximum oil capacity of 28 L (7 gal) in high speed compartment and 30 L (8 gal) in the epicyclic

machine automation and communication

Levels of AutomationState-based shearer automation “Navigator 2”

Levels of AutomationZone-based automation “Navigator 1”

Levels of Automation“Longwall Navigator” for improved face alignment and horizon control

Levels of AutomationIntegrated longwall automation with “Navigator 2 + 3”

TypePMC Evo-S control system allows the shearer to be operated even if the overall control system is not functioning.

TypeThe shearer is equipped with a state-of-the-art industry PC in a flame-proof housing with plenty of computing power.

TypeState-of-the-art industry PC allows flexibility to upgrade to future features such as condition monitoring.

TypeUnlike competitor systems, modularity of the longwall system

control allows the longwall to operate in “faulttolerant” mode

Machine Automation and CommunicationType

in other words integrated automation does not prevent control via individual plc’s in order to keep production up and running

Machine Automation and CommunicationType

pmc evos control system with stateoftheart ethernet communication and backup functionality

Machine Automation and CommunicationType

this shearer has a stateoftheart distributed automation system for the control monitoring and protection of the shearer

Machine Automation and CommunicationType

a programmable logic controller plc takes care of basic machine control tasks ensuring that coal is produced

Machine Automation and CommunicationType

industryleading automation from the pioneer of statebased automation

Machine Automation and CommunicationType

its modular design allows it to be configured to meet individual control needs

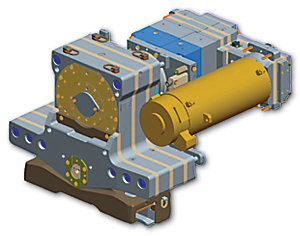

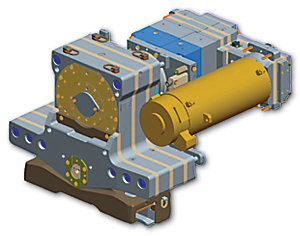

Downdrive - DD125Type

suitable for all current rack type systems

Downdrive - DD125Type

transmission rating of 125 kw 168 hp

Downdrive - DD125Type

maximum haulage pull 945 kn 107 tons

Downdrive - DD125Type

innovative and unique downdrive design

Downdrive - DD125Type

removable modular top drive wheel assembly cartridge

Downdrive - DD125Type

downdrive ratio 17t—23t—10t two wheel configuration

Downdrive - DD125Type

trapping shoe with replaceable wear inserts safe and easy to replace unique to caterpillar

Downdrive - DD125Type

fully removable rehandable modular gearbox

Haulage Transformer Box - HTB2Type

module contains drive system circuit breaker and one 250 kw 600v ac inverter drive with regenerative braking module

Haulage Transformer Box - HTB2Type

this flameproof module contains the main 253 kva haulage transformer power supplies and auxiliary transformer

Electrical MaterialType

this model of shearer is available with headlights cameras methane monitoring end displays and audible alarms

Electrical MaterialType

all electrical material is designed and certified to iec standards and also complies with other regional and national standards

Dimensions (Approximate) - LowAFC Pan Width - Maximum

13420 mm

Dimensions (Approximate) - LowAFC Pan Width - Minimum

10320 mm

Dimensions (Approximate) - LowClearance from Drum to AFC Toeplate

3000 mm

Dimensions (Approximate) - LowCutting Heights - Maximum

39300 mm

Dimensions (Approximate) - LowCutting Heights - Minimum

18000 mm

Dimensions (Approximate) - LowDiameter of Shearer Cutting Drum

16000 mm

Dimensions (Approximate) - LowDistance between Drums with Arms Horizontal

141550 mm

Dimensions (Approximate) - LowDistance between Ranging Arm Hinge Points

85250 mm

Dimensions (Approximate) - LowDistance between Trapping Shoe Centers

64530 mm

Dimensions (Approximate) - LowHeight to Top of Machine Main Body

14440 mm

Dimensions (Approximate) - LowMachine Height over Main Body

Dimensions (Approximate) - LowMaximum Cutting Drum Overall Width

11500 mm

Dimensions (Approximate) - LowRanging Arm Cutting Drum Diameter

16000 mm

Dimensions (Approximate) - LowRanging Arm Length (Hinge to Drum)

28150 mm

Dimensions (Approximate) - LowShearer Drum Undercut of Floor

6190 mm

Dimensions (Approximate) - LowVertical Tunnel Clearance

5980 mm

Dimensions (Approximate) - Mid-HighAFC Pan Width - Maximum

13420 mm

Dimensions (Approximate) - Mid-HighAFC Pan Width - Minimum

10320 mm

Dimensions (Approximate) - Mid-HighClearance from Drum to AFC Toeplate

3000 mm

Dimensions (Approximate) - Mid-HighCutting Heights - Maximum

43600 mm

Dimensions (Approximate) - Mid-HighCutting Heights - Minimum

22000 mm

Dimensions (Approximate) - Mid-HighDiameter of Shearer Cutting Drum

Dimensions (Approximate) - Mid-HighDistance between Drums with Arms Horizontal

141550 mm

Dimensions (Approximate) - Mid-HighDistance between Ranging Arm Hinge Points

85250 mm

Dimensions (Approximate) - Mid-HighDistance between Trapping Shoe Centers

66120 mm

Dimensions (Approximate) - Mid-HighHeight to Top of Machine Main Body

15710 mm

Dimensions (Approximate) - Mid-HighMachine Height over Main Body

Dimensions (Approximate) - Mid-HighMaximum Cutting Drum Overall Width

11500 mm

Dimensions (Approximate) - Mid-HighRanging Arm Cutting Drum Diameter

22000 mm

Dimensions (Approximate) - Mid-HighRanging Arm Length (Hinge to Drum)

28150 mm

Dimensions (Approximate) - Mid-HighShearer Drum Undercut of Floor

7930 mm

Dimensions (Approximate) - Mid-HighVertical Tunnel Clearance

7250 mm

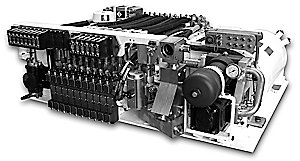

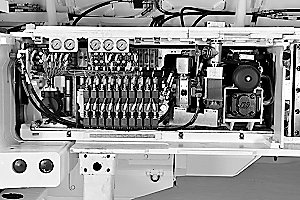

Powerpack - PP2Type

operating system pressure of 260 bar 3770 psi

Powerpack - PP2Type

integral monitoring transducers

Powerpack - PP2Type

for use with iso 68 or iso 100 hydraulic oils

Powerpack - PP2Type

robust hydraulic reservoir of 165 l 436 gal capacity

Powerpack - PP2Type

this unit has a pump motor rating of 30 kw @ 50 hz 48 hp @ 60 hz

Powerpack - PP2Type

fixed displacement pump with a capacity of 50 lmin 1321 galmin

Powerpack - PP2Type

available with 6 section valve bank

Hydraulic MaterialType

all hose and hosing is in compliance with guideline mdg 41 and msha regulations

Hydraulic MaterialType

the hoses are assembled to hose assembly standard din2006620110

Hydraulic MaterialType

all hose assemblies are to iso 6805 and proof tested to en iso 1402

OptionsType

available with machine parking brake

OptionsType

available with machine position encoder

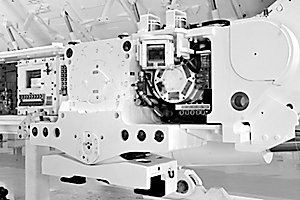

Mainframe - MF2Type

maximum protection of electrical boxes providing the highest level of flameproof integrity

Mainframe - MF2Type

improved access for maintenance and ease of overhaul and repair

Mainframe - MF2Type

versatility of application due to fully modular construction

Mainframe - MF2Type

high structural integrity and absorption of all cutting and haulage forces providing maximum protection for all major units

Mainframe - MF2Type

a split mainframe is available in case of transportation limitations

Dimensions (Approximate) - HighAFC Pan Width - Maximum

13420 mm

Dimensions (Approximate) - HighAFC Pan Width - Minimum

10320 mm

Dimensions (Approximate) - HighClearance from Drum to AFC Toeplate

3000 mm

Dimensions (Approximate) - HighCutting Heights - Maximum

45700 mm

Dimensions (Approximate) - HighCutting Heights - Minimum

25000 mm

Dimensions (Approximate) - HighDiameter of Shearer Cutting Drum

Dimensions (Approximate) - HighDistance between Drums with Arms Horizontal

141550 mm

Dimensions (Approximate) - HighDistance between Ranging Arm Hinge Points

85250 mm

Dimensions (Approximate) - HighDistance between Trapping Shoe Centers

60560 mm

Dimensions (Approximate) - HighHeight to Top of Machine Main Body

16470 mm

Dimensions (Approximate) - HighMachine Height over Main Body

Dimensions (Approximate) - HighMaximum Cutting Drum Overall Width

11500 mm

Dimensions (Approximate) - HighRanging Arm Cutting Drum Diameter

25000 mm

Dimensions (Approximate) - HighRanging Arm Length (Hinge to Drum)

28150 mm

Dimensions (Approximate) - HighShearer Drum Undercut of Floor

8660 mm

Dimensions (Approximate) - HighVertical Tunnel Clearance

8010 mm

Machine @ 60 HzAvailable Cutting Power

2 x 597 kw 2 x 800 hp 2 x 746 kw 2 x 1000 hp 2 x 895 kw 2 x 1200 hp

Machine @ 60 HzBody Height

6000 mm

Machine @ 60 HzCutting Drum Diameter

16002500 mm 63985 in

Machine @ 60 HzCutting Drum Speed

394 449 and 543 rpm

Machine @ 60 HzHaulage Motor

2 x 125 kw 2 x 168 hp

Machine @ 60 HzHaulage Pull

up to 1049 kn 107 tons

Machine @ 60 HzHaulage Speed

up to 30 mmin 985 ftmin

Machine @ 60 HzHaulage System

ac inverter drive

Machine @ 60 HzInstalled Power

up to 1780 kw up to 2387 hp

Machine @ 60 HzMachine Weight (approximate)

780 tonnes

Machine @ 60 HzMinimum Pan Width

10320 mm

Machine @ 60 HzOperating Voltage

41600 volts

Machine @ 60 HzPump Motor

300 kw

Machine @ 60 HzSeam Range

1845 m 71177 in

Machine @ 60 HzTypical Machine Length (drum centers)

140820 mm

BENEFITS AND FEATURES

SHEAR PERFORMANCE

With high-powered ranging arms and haulage units, Cat shearers cut and load up to 5000 ...

LEARN MORE

KEY IMPROVEMENTS

Cat shearers incorporate numerous new features and benefits. These are presented in the ...

LEARN MORE

MAINFRAME MADE FOR MUSCLE...

The unique mainframe of the Cat shearer is one of its key features. The fabricated ...

LEARN MORE

INNOVATIVE TRAPPING SHOE

Trapping shoes attach the shearer to the haulage rack system, part of the armored face ...

LEARN MORE

EXTENDED SERVICE LIFE

The inserts have the same wear area as conventional shoes and are articulated.

LEARN MORE

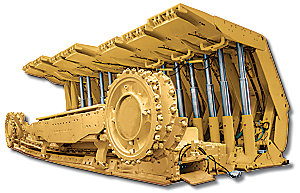

DOWNDRIVE

An innovative downdrive design results in longer bearing life, increased gear rating and ...

LEARN MORE

MODULAR HAULAGE SYSTEM

Caterpillar has further developed its modular haulage concept with increased power ...

LEARN MORE

COALSIZER

Cat shearers can be supplied with an optional rugged coalsizer, currently with up to 200 ...

LEARN MORE

PACKING MORE POWER

The power pack has been reengineered to provide increased functionality, optimized ...

LEARN MORE

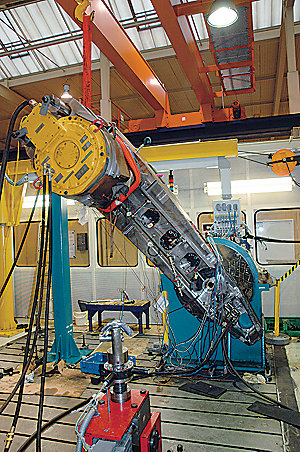

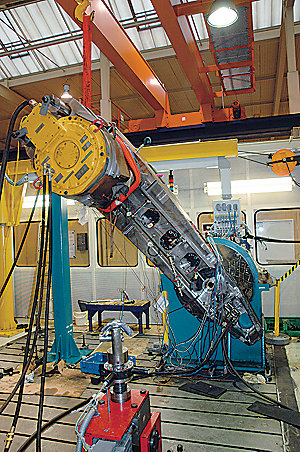

TESTED FOR RELIABILITY

Downtime is extremely expensive for operators - costs continue to add up while nothing is ...

LEARN MORE

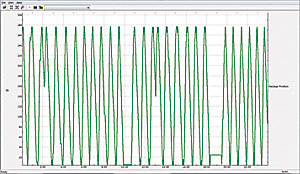

LUBRICATION VERIFICATION

Ranging arms and haulage units are subjected to an intense test regime to establish the ...

LEARN MORE

ENDURANCE BLOCK LOAD TESTING

This test applies loads far in excess of those encountered during normal mining ...

LEARN MORE

PRODUCTION LOAD TESTING

After successful endurance block load testing, the same test rigs are used to carry out ...

LEARN MORE

PROVEN PRODUCTIVITY

This extensive range of tests ensures the highest possible availability of shearers in ...

LEARN MORE

INDUSTRY-LEADING AUTOMATION ...

Caterpillar has developed a state-of-the-art distributed automation system for the ...

LEARN MORE

POWER AND FLEXIBILITY

With extensive computer power installed and simple upgrade to new features, Cat shearer ...

LEARN MORE

THE NET IS THE CONTROL

The shearer control system uses a state-of-the-art Ethernet bus, resulting in a drastic ...

LEARN MORE

INTRINSIC SAFETY

More components designed to be intrinsically safe means simpler installation and speedier ...

LEARN MORE

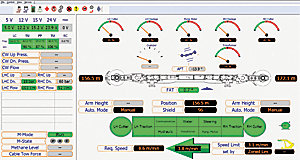

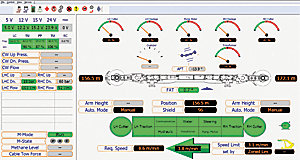

VISUALIZATION

Visualization not only provides a graphical representation of current operating ...

LEARN MORE

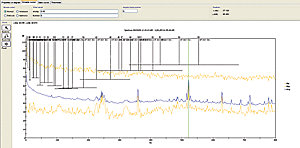

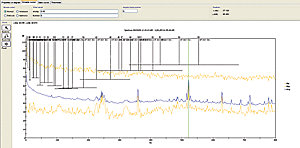

VIBRAGUARD™

VibraGuard™ allows trained personnel to predict machine component wear, avoid unplanned ...

LEARN MORE

MODULAR CONTROL OFFERS ...

PMC™ Evo-S brings state-of-the art processor performance underground. Designed by the ...

LEARN MOREEL2000 STANDARD EQUIPMENT

- trapping shoe ix

- central lubrication system

- pmc™ evos

- gate end data connection

Powerline

WLAN

EL2000 OPTIONS

- multipiece mainframe

- cowl

- spall guards

- coal sizer

100 kW - trapping shoe ix insert exchange

- shearer clearer

- spray bars

- ipc

- zonebased automation“navigator 1”

- statebased shearer automation “navigator 2”

- integrated longwall automation with “navigator 2 + 3” only with cat longwall equipment

- “longwall navigator” for improved face alignment and horizon control incorporates lasc technology only with cat longwall equipment

- vibraguard™

- cameras

- condition monitoring

MOTEUR

With high-powered ranging arms and haulage units, Cat shearers cut and load up to 5000 tonnes (5,500 tons) per hour and more, depending on mining conditions. The unique, one-piece mainframe design offers maximum structural integrity and service life.

BENEFITS AND FEATURES

The mainframe is available as a split unit in the event of transportation limitations. Featuring the superior Jumbotrack shearer haulage system, the shearer also offers advanced integrated automation and communication options.

Cat shearers incorporate numerous new features and benefits. These are presented in the following pages by category.

BENEFITS AND FEATURES

The key improvements include:

- Extremely powerful PMC™ Evo-S control system with state-of-the-art Ethernet communication

- Improved innovative downdrive design

- Ranging arm with longer service life

- Further development of the modular haulage and electrical control box

- Enhanced power pack with easy access

- Online vibration monitoring with VibraGuard™

- Clear wiring and use of plug and play for easy maintenance

- Trapping Shoe Ix (Insert Exchange) for longer service life, safe and easy to replace

- Future-proof design allowing upgrades - such as stronger ranging arms and haulage units or addition of coal sizer - during rebuild

- Mainframe designed to handle 1200 kW (1,930 hp) ranging arms and 200 kW (320 hp) haulage units - EL3000 only

The unique mainframe of the Cat shearer is one of its key features. The fabricated structure of the mainframe with cast ranging-arm hinge points results in an extremely robust design not only to meet the toughest mining conditions and ensure reliability and long service life, but also to handle even higher cutting and haulage forces in the future. The mainframe of the EL3000 is designed to allow retrofit of 1200 kW (1,930 hp) ranging arms and 200 kW (320 hp) haulage units. A split mainframe is available in case of transportation limitations.

BENEFITS AND FEATURES

Benefits

- High structural integrity and absorption of all cutting and haulage forces, providing maximum protection for all major units

- Maximum protection of electrical boxes, providing the highest level of flameproof integrity

- Improved access for maintenance and ease of overhaul and repair

- Versatility of application due to fully modular construction

- Flexible and cost-effective equipment management

- Independent unit exchange and selective overhaul

- Long service life

- Low operational costs

- High reliability

Trapping shoes attach the shearer to the haulage rack system, part of the armored face conveyor, allowing the shearer to be hauled up and down the face.

BENEFITS AND FEATURES

A new type of trapping shoe developed by Caterpillar - the Trapping Shoe Ix - offers numerous advantages over the conventional design:

- Greater safety and ease of handling during replacement

- Faster replacement

- Greater flexibility

- Longer service life

- Lower operating costs

The inserts have the same wear area as conventional shoes and are articulated.

BENEFITS AND FEATURES

This - combined with the fact that the shoe does not have to exert as much pressure, resulting in a lower point load - means less wear. Field tests of the Trapping Shoe Ix showed its service life to be 50 percent longer than conventional trapping shoes.

An innovative downdrive design results in longer bearing life, increased gear rating and greater modularity for simplified maintenance. Height adjustment of the shearer is relatively easy and is achieved with replacement of the downdrive to allow adaption to changing seam conditions.

BENEFITS AND FEATURES

Every mainframe is designed to take the full range of downdrive arrangements to fit a wide range of seam heights.

- Fully modular design

- Easy maintenance access

- Fully articulating shoe

- High pull and maximum life

Caterpillar has further developed its modular haulage concept with increased power rating, gear rating, bearing life and redundancy, leading to longer overhaul intervals based on typical usage. The haulage system is a simple design capable of achieving cutting speeds of up to 32 m/min (105 ft/min), with improved reliability and longer service life.

BENEFITS AND FEATURES

The fully modular haulage gearbox is located in the shearer mainframe and does not form part of the shearer structure. The haulage system offers:

- Simple construction, improved reliability and longer service life

- Fully proven load-sharing system

- Reduced cost

Cat shearers can be supplied with an optional rugged coalsizer, currently with up to 200 kW (320 hp) of installed power for maximum productivity in high seams or difficult mining conditions.

BENEFITS AND FEATURES

The coalsizer can be ordered separately for installation during rebuild or overhaul.

The power pack has been reengineered to provide increased functionality, optimized performance and better access to filtration units via simplified layout. Both of the following units are modular, with drawer units providing easy access and upgrade.

BENEFITS AND FEATURES

Features Transformer Box

- Features closed-loop control with measurement of speed, not power

- Transforms to 600 V for haulage units’ frequency converter motors

- Connectorized cables for reduced wiring and quick, clear installation

- Temperature monitoring and water cooling

Control Box

- Plug and play

- Easy to maintain

- Quick and easy troubleshooting

Downtime is extremely expensive for operators - costs continue to add up while nothing is produced. This is why Caterpillar ensures that our superbly engineered shearers are up to the job.

BENEFITS AND FEATURES

That’s why each shearer design - which is optimized for maximum availability - is subjected to rigorous in-house testing to ensure that there are no unpleasant surprises when units are in service. Shearer production quality assurance falls into three main categories: lubrication verification, endurance block load testing and production load testing.

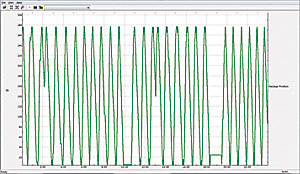

Ranging arms and haulage units are subjected to an intense test regime to establish the optimum oil-level requirements to suit all mining conditions. The units are mounted on purpose-designed test rigs that are positioned to simulate the gradient of the underground seam.

BENEFITS AND FEATURES

A suite of tests is performed with a range of different gradients and arm positions to represent even the most severe mining conditions. The units are operated until stable temperatures are achieved at all gradients. This establishes the minimum, maximum and optimum oil quantities for all conditions.

This test applies loads far in excess of those encountered during normal mining operations, ensuring that the shearer can operate reliably at the installed power ratings. Ranging arms or haulage units are mounted on purpose-designed test rigs in a back-to-back configuration driven by a suitable test motor.

BENEFITS AND FEATURES

The endurance block load test imposes loads from 100% to 175% to ensure that the ranging arm design meets the requirements of the most demanding applications. Input torque, losses and output torque are monitored during the test, as are bearing, gear and shaft temperatures. Vibration is monitored by dedicated sensors. Oil samples are collected at intervals for analysis, as the presence of metal in the oil can indicate excessive component wear. On completion of the endurance test, units are dismantled for a full internal and external inspection to verify that the design is fit for purpose.

After successful endurance block load testing, the same test rigs are used to carry out production load testing of all ranging arms and haulage units.

BENEFITS AND FEATURES

The test gradually increases the load up to full load. All temperatures and vibration points are monitored during the test, and oil samples are again collected for analysis.

This extensive range of tests ensures the highest possible availability of shearers in service and maximum return on investment for your longwall installation.

BENEFITS AND FEATURES

Nothing is left to chance in ensuring that our shearers are unsurpassed in reliability.

Caterpillar has developed a state-of-the-art distributed automation system for the control, monitoring and protection of the shearer. Its modular design allows it to be configured to meet individual control needs, from basic monitoring and protection to advanced automation and data transmission.

BENEFITS AND FEATURES

The PMC™ Evo-S control system with state-of-the-art Ethernet communication and backup functionality allows the shearer to be operated even if the overall control system is not functioning. In 2002, State-Based Automation was invented and launched. Using this technology, Caterpillar now offers a comprehensive range of automation products.

With extensive computer power installed and simple upgrade to new features, Cat shearer automation is fit for the future. Components connect into the network rather than directly to a central computer, simplifying installation, wiring, maintenance and troubleshooting.

BENEFITS AND FEATURES

The shearer is equipped with a state-of-the-art industry PC in a flame-proof housing with plenty of computing power, allowing flexibility to upgrade to future features such as condition monitoring. A Programmable Logic Controller (PLC) takes care of basic machine control tasks, ensuring that coal is mined. Unlike competitor systems, the modularity of the longwall system and control allow the longwall to operate in “fault-tolerant” mode, even when there is a problem with the overall automation system. In other words, integrated automation does not prevent control via individual PLCs in order to keep production up and running.

The shearer control system uses a state-of-the-art Ethernet bus, resulting in a drastic reduction in wiring and a huge increase in flexibility. There are no interfacing problems, as equipment connected to the network only needs to be able to communicate via Internet Protocol.

BENEFITS AND FEATURES

Commissioning, maintenance, upgrades and troubleshooting are much easier and faster, and equipment is self-configuring. The few cables that are used are standard Ethernet cables rather than application-specific cables - cutting costs and simplifying spare parts inventories. Flameproof housings are no longer required, simplifying installation and speeding up maintenance. New modules are based on standardized CIOS™ modules (configurable input output system), resulting in a plug and play approach to upgrades. No reprogramming is necessary. Remote control and diagnosis are also possible for all components. And because of the Ethernet-based approach, the failure of one component does not impact the whole system.

More components designed to be intrinsically safe means simpler installation and speedier maintenance. New modules are based on standardized CIOS™ modules, resulting in a plug and play approach to upgrades.

BENEFITS AND FEATURES

Changes to the system only require commissioning changes - such as mounting and connection of sensors. No replacement of control software is required. Remote control and diagnosis are also possible for all components. And because of the Ethernet-based approach, the failure of one component does not impact the whole system. This not only supports the unique “fault-tolerant” mode, which allows the longwall to continue to operate when there is a problem with the overall automation system, but also, through systematic isolation, allows faulty units to be identified while production continues.

Visualization not only provides a graphical representation of current operating conditions, but can also display historical conditions and a graphic display of trends. An automated longwall is a highly complex system with many interacting components generating time-variant data.

BENEFITS AND FEATURES

Visualization gives operators a better understanding of the overall system, allowing them to further optimize operations. VLongwall provides a system overview and access to the dedicated visualization modules VShield, VDrive, VPlow and VShearer. It also gives access to VTrend for trend analysis and VGraph3D for waterfall plots of the entire longwall.

VibraGuard™ allows trained personnel to predict machine component wear, avoid unplanned downtime and set alarms to warn the operator if monitored machine components run the risk of damage. This comprehensive protection backs long life and high availability of your valuable mining equipment.

BENEFITS AND FEATURES

Benefits

- Permanent online monitoring and protection of equipment instead of sporadic offline measurements

- Assists in the prediction of machine component wear

- Alarms warn the operator if monitored components are at risk of damage

- When utilized by trained personnel, VibraGuard™ makes repairs predictable and helps avoid unplanned downtime

- Repair work can be done largely without stress

- Allows timely procurement of spare parts

- Transfers data to a surface control center PC for detailed analysis and evaluation

PMC™ Evo-S brings state-of-the art processor performance underground. Designed by the market leader in shearer automation, the advanced Cat automation package allows improved utilization of manpower in a safe environment; with increased yield from any given seam section, faster haulage speeds, improved face management and increased life of all longwall equipment, including AFC and shields.

BENEFITS AND FEATURES

Automation systems match your needs - from basic to highly sophisticated - while remaining easy to install, operate and maintain. The modular control concept is:

- Easily expandable based on modular design

- Ready for integration of highly sophisticated technologies and devices

- Equipped for XML-based interfaces to third- or fourth-party systems

Making it Easy

- Cat self-configuring controls and standard interfaces such as Ethernet allow quick and easy system configuration changes with no programming effort

- Ready for future technologies such as high-quality condition monitoring, including vibration monitoring

- Easy and flexible adaptation to existing data environments

- Greater use of Ethernet, standard connectorization and PMC™ control family mean greater simplicity, reduced spares inventories and shorter downtimes

- Standardization and modularization allow quick and easy customization of components and systems

Fast Troubleshooting

- Widespread use of intrinsically safe components allows large-scale fault diagnosis under power

- Remote access to most components down to I/O level

- Diagnosis from surface or by Cat Mine Control Center

- Managed switches and field bus coupler (FBC) allows selective routing:

Less Maintenance Effort

- Widespread use of intrinsically safe components in PMC™ Evo-S reduces time-consuming opening of flame-proof housings in the event of faults.

- Quick and easy exchange of modules.

Modularity is Strength Modularity is a key feature of the Cat shearer. It results in independent major units, each driven by its own dedicated electric motor and housed within or attached to a robust mainframe unique to the Cat range. Control systems are also modular. This modular design offers maximum availability - through “fault-tolerant” mode operation - and the flexibility to meet even the most demanding customer requirements by upgrading components such as the ranging arm.