PMC-D/PMC-D20 DRIVE CONTROL UNIT

The intrinsically safe Cat® PMC-D control is used on shearer or plow faces to provide high level AFC (armed face conveyor) and plow automation. Each Drive unit needs to be equipped with one PMC-D control unit and equivalent I/O to operate the CST drives or UEL gearbox functions. In such a system a Cat PMC-V provides the Human Machine Interface (HMI) to interfere with the PMC-D controls to operate manual mode, visualize and change parameters and show actual process values. Within a PMC-D system minimum one and typically up to 3 PMC-Vs are in equal operation. The PMC-D system can control extremely sensitive the speed and torque of highly powered AFC CST drive. Using Profibus network all PMC-Ds and PMC-Vs in a system could exchange process data over long distances with high frequency.

SPECIFICATIONS

Operating SystemµITRON RTOS

Processor32Bit RISC Microcontroller TX1940CYAF, 32MHz, internal RAM 10Kbytes, ROM 256Kbytes

RAM Memory4Mbytes CMOS Static RAM, 4Mbytes Flash

BENEFITS AND FEATURES

attributes of pmcdpmcd20 ...

LEARN MORE

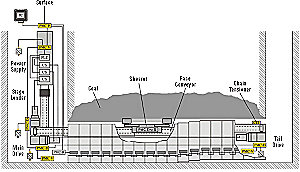

exemplarily system layout of ...

LEARN MOREcomponents

Operating SystemµITRON RTOS

Processor32Bit RISC Microcontroller TX1940CYAF, 32MHz, internal RAM 10Kbytes, ROM 256Kbytes

RAM Memory4Mbytes CMOS Static RAM, 4Mbytes Flash

electrical sockets

Socket 1 - Pin 1Optocoupler Anode

Socket 1 - Pin 2Relay Contact NO: a

Socket 1 - Pin 3Relay Contact NO: b

Socket 1 - Pin 4Optocoupler Cathode

Socket 10 - Pin 1+12 V (output)

Socket 10 - Pin 2Multi Mode Input 3

Socket 10 - Pin 3+8.2 V (output)

Socket 10 - Pin 4GND

Socket 11 - Pin 1+12 V (output)

Socket 11 - Pin 2Multi Mode Input 6

Socket 11 - Pin 3+8.2 V (output)

Socket 11 - Pin 4GND

Socket 12 - Pin 2TP a

Socket 12 - Pin 3TP b

Socket 13 - Pin 2CM-Sensor +

Socket 13 - Pin 3CM-Sensor -

Socket 13 - Pin 4CM-GND

Socket 14 - Pin 2CM-Sensor +

Socket 14 - Pin 3CM-Sensor -

Socket 14 - Pin 4CM-GND

Socket 15 - Pin 2CM-Sensor +

Socket 15 - Pin 3CM-Sensor -

Socket 15 - Pin 4CM-GND

Socket 16 - Pin 2CM-Sensor +

Socket 16 - Pin 3CM-Sensor -

Socket 16 - Pin 4CM-GND

Socket 17 - Pin 2CM-Sensor +

Socket 17 - Pin 3CM-Sensor -

Socket 17 - Pin 4CM-GND

Socket 18 - Pin 2CM-Sensor +

Socket 18 - Pin 3CM-Sensor -

Socket 18 - Pin 4CM-GND

Socket 19 - Pin 2CM-Sensor +

Socket 19 - Pin 3CM-Sensor -

Socket 19 - Pin 4CM-GND

Socket 2 - Pin 1+12 V (A) (output)

Socket 2 - Pin 2Serial Interface: RxD_0

Socket 2 - Pin 3Serial Interface: TxD_0

Socket 2 - Pin 4GND

Socket 20 - Pin 2CM-Sensor +

Socket 20 - Pin 3CM-Sensor -

Socket 20 - Pin 4CM-GND

Socket 3 - Pin 1+12 V (B) (output)

Socket 3 - Pin 2Serial Interface: RxD_B

Socket 3 - Pin 3Serial Interface: TxD_B

Socket 3 - Pin 4GND

Socket 4 - Pin 1+12 V (C) (output)

Socket 4 - Pin 2Serial Interface: RxD_C

Socket 4 - Pin 3Serial Interface: TxD_C

Socket 4 - Pin 4GND

Socket 5 - Pin 1+12 V (C) (output)

Socket 5 - Pin 2Switch 1

Socket 5 - Pin 3Switch 2

Socket 5 - Pin 4GND

Socket 6 - Pin 2Profibus: a (internal)

Socket 6 - Pin 3Profibus: b (internal)

Socket 7 - Pin 1+12 V (Power Supply)

Socket 7 - Pin 4GND (Power Supply)

Socket 8 - Pin 1Multi Mode Input 4

Socket 8 - Pin 2Multi Mode Input 1

Socket 8 - Pin 3+8.2 V (output)

Socket 8 - Pin 4GND

Socket 9 - Pin 1Multi Mode Input 5

Socket 9 - Pin 2Multi Mode Input 2

Socket 9 - Pin 3+8.2 V (output)

Socket 9 - Pin 4GND

global certifications

TypesEurope: ATEX

TypesU.S.: MSHA

TypesMore certifications on demand

TypesAustralia: IECEx, ANZEx

TypesChina: MA

TypesRussia: GOST

health for longwall vibration analysis

Provides vibration monitoring functionality for longterm health monitoring of the following longwall related equipment:• CST gearbox and relating motor • UEL gearbox and relating motor

Provides vibration monitoring functionality for longterm health monitoring of the following longwall related equipment:• Shearer haulage and ranging arm gearboxes • Water/HFA pump station

Provides vibration monitoring functionality for longterm health monitoring of the following longwall related equipment:• Stage loader gearbox and relating motor • Crusher and relating motor

pmcd dimensions and plug assignments approximate

Height148.0 mm

Length335.0 mm

Width278.0 mm

pmcd20 dimensions and plug assignments approximate

Height125.0 mm

Length335.0 mm

Width279.0 mm

electrical data

Supply Current - Maximum Ratings1.5 amps

Supply Current - Typical Value1.0 amps

Supply Voltage - Maximum Ratings9.5 V - 13.2 V

Supply Voltage - Typical Value12 V DC

environmental data

Temperature - Maximum Ratings-20° C - +40° C (-4° F - +104° F)

Temperature - SymbolTamb

Temperature - Typical Value20.0 ° C

BENEFITS AND FEATURES

ATTRIBUTES OF PMC-D/PMC-D20 ...

LEARN MORE

EXEMPLARILY SYSTEM LAYOUT OF ...

LEARN MOREMOTEUR

BENEFITS AND FEATURES

- Robust stainless steel design

- Highly reliable OS37 plug technology for complete gear box control

- SKK24 hose cables for bus system and additional I/O connection

- IP 68 rating (48 hr @ 1 m [3.28 ft] under water)

- HMI with 24 multi feedback keys (pressure point, led light)

- 63.5 mm (2.5 in) graphical monochrome display

- Multi language support

- Maintainability (brass bar mounting)

- Optional eight (8) additional ports for acceleration sensors (PMC-D20)

BENEFITS AND FEATURES

BENEFITS AND FEATURES

- “Distributed controller Intelligence per drive”

- Synchronized heavy load start up

- Soft start up

- Load sharing between conveyor drives

- Overload protection

- Motor braking feature

- Further used in plow operations:

BENEFITS AND FEATURES

- Usage of PMC-D for chain tensioning of AFC (front and rear conveyor) and Beam Stage Loader (BSL)

- In conjunction with Slacktronik direct BSL chain slack control and relating chain tensioning

- Usage of PMC-D for high accurate plow position control and monitoring

- Support VFD controlled drive applications

- Optional integration of “HEALTH for Longwall Vibration Analysis” function with PMC-D20 control unit: