773G OFF-HIGHWAY TRUCK

G Series represents a new era for the 773, and with your long-term success as our goal, we’ve developed this truck to be more productive and economical. It offers your operators the confidence, comfort and control to run at peak efficiency, and it can feed your crushers and haul material at a lower cost per ton. When you also consider its performance and fuel efficiency, the 773G is the right truck for our generation.

SPECIFICATIONS

Nominal Payload Class (100%)56.0 tonnes

Top Speed - Loaded67.6 km/h

Body Capacity - SAE 2:135.75 m3

BENEFITS AND FEATURES

operating specifications

Nominal Payload Class (100%)56.0 tonnes

Top Speed - Loaded67.6 km/h

Body Capacity - SAE 2:135.75 m3

Maximum Working Payload (110%)61.5 tonnes

Not to Exceed Payload (120%)*67.1 tonnes

engine

Engine ModelCat® C27 ACERT™

Rated Engine Speed2000.0 RPM

Gross Power - SAE J1995578.0 kW

Net Power - SAE J1349546.0 kW

Net Power - 80/1269/EEC552.0 kW

Net Power - ISO 9249552.0 kW

Bore137.0 mm

Stroke152.0 mm

Displacement27.0 L

Engine Power - ISO 14396569.0 kW

Net Torque3646.0 N·m

Peak Torque Speed1300.0 RPM

weights approximate

Maximum Gross Vehicle Weight102740.0 kg

capacity dual slope 100% fill factor

Struck26.86 m3

Heaped 2:1 (SAE)35.75 m3

capacity flat floor 100% fill factor

Struck26.25 m3

Heaped 2:1 (SAE)35.49 m3

weight distributions approximate

Front Axle - Empty53.0 %

Front Axle - Loaded35.0 %

Rear Axle - Empty47.0 %

Rear Axle - Loaded65.0 %

transmission

Forward 110.8 km/h

Forward 215.1 km/h

Forward 320.4 km/h

Forward 427.4 km/h

Forward 537.0 km/h

Forward 650.1 km/h

Forward 767.6 km/h

Reverse14.1 km/h

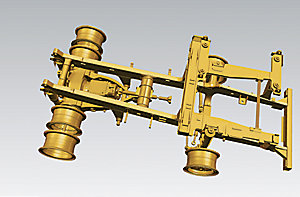

final drives

Differential Ratio3.64:1

Planetary Ratio4.80:1

Total Reduction Ratio17.49:1

brakes

Brake Surface - Front655.0 cm2

Brake Surface - Rear61269.0 cm2

Brake StandardsISO 3450:1996

service refill capacities

Fuel Tank795.0 L

Cooling System171.0 L

Differentials and Final Drives145.0 L

Steering Tank36.0 L

Steering System (Includes Tank)54.0 L

Brake Hoist System322.0 L

Brake/Hoist Hydraulic Tank176.0 L

Crankcase90.0 L

Torque Converter/Transmission System HRC70.0 L

Torque Converter/Transmission System LRC61.0 L

body hoists

Pump Flow - High Idle448.0 L/min

Relief Valve Setting - Raise17250.0 kPa

Relief Valve Setting - Lower3450.0 kPa

Body Raise Time - High Idle9.5 Seconds

Body Lower Time - Float13.0 Seconds

Body Power Down - High Idle13.0 Seconds

suspension

Rear Axle Oscillation8.1 Degrees

Empty Loaded Cylinder Stroke Front234.0 mm

Empty Loaded Cylinder Stroke Rear149.0 mm

sound

Sound StandardsStandards

rops

ROPS/FOPS StandardsStandards

steering

Turning Diameter - Front23.5 m

Steering StandardsSAE J1511 FEB94 ISO 5010:1992

Steer Angle31.0 Degrees

Turning Circle Clearance Diameter26.1 m

tires

Standard Tire24.00R35 (E4)

BENEFITS AND FEATURES

773G (Tier 2) STANDARD EQUIPMENT

- power train

For non-regulated regions only: - Direct drive fan - MEUI-A fuel system

Braking system: - Automatic Retarder Control (ARC) - Manual retarder (utilizes rear oil cooled, multiple disc brakes) - Brake release motor (towing) - Dry disc brakes (front) - Front brake disconnect switch (front) - Oil-cooled multiple disc brakes (rear) - Brake wear indicator (rear) - Parking brake - Secondary brake - Service brake

Transmission: - 7 speed automatic powershift with: • Electronic Clutch Pressure Control (ECPC) • Advanced Productivity Electronic Control Strategy (APECS) - Automatic neutral idle - Autostall - Second gear start - suspension systems

Suspension, front and rear (EU compliant) - electrical

Alarm backup

Alternator, 120 Amp

Autolube power supply ready

Batteries, maintenance-free, 12V (2), 1,400 CCA combined

Electrical system, 25 Amp, 24V to 12V converter

Lighting system: - Backup light (halogen) - Directional signals/hazard warning (front and rear LED) - Engine compartment light - Headlights, (halogen) with dimmer - Operator access courtesy lights - Side profile lights - Stop/tail lights (LED)

Service center containing: - Battery jump start - Breakers with spare fuses - Lock out switch - Ports, ET and VIMS - Service lockout switch (power without engine start) - technology products

Economy Modes, standard and adaptive

Product Link, cellular or satellite

Traction Control System (TCS)

Truck Production Management System (TPMS)

Vital Information Management System (VIMS) - operator environment

Advisor display: - Fluid level monitoring - Fuel level monitoring - Display languages (market based)

Air conditioning/heat

Automatic temperature control

Ashtray and cigarette lighter

Coat hook

Cup holders (4)

Diagnostic connection port, 24V

Entertainment radio ready: - 5 amp converter - Speakers - Antenna - Wiring harness

Foot rest

Gauges/indicators: - Brake oil temperature gauge - Coolant temperature gauge - Engine overspeed indicator - Fuel level - Hour meter - Speedometer with odometer - Tachometer - Transmission gear indicator

Hoist lever

Horn

Light - courtesy

Light - dome

Mirrors, non-heated

Power port, 24V and 12V (2)

Rollover Protection (ROPS)/Falling Object Protection (FOPS)

Seat, Cat Comfort Series III: - Full air suspension - Retractable 3-point seat belt with shoulder harness

Seat, training with lap belt

Steering wheel, padded, tilt and telescopic

Storage compartment

Sun visor

Throttle lock

Window, hinged, right side (emergency exit)

Window, powered, left side

Windshield wiper intermittent and washer - guards

Driveline

Engine crankcase

Fan - fluids

Antifreeze

Extended life coolant to -34° C (-30° F)

Grouped ground-level filters - other standard equipment

Body down indicator

Body safety pin (secures body in up position)

Center mounted rims

Fuel tank, 795 L (210 gal)

Ground level battery disconnect

Ground level engine shutdown

Ground level grease fittings

Operator Maintenance Manual (OMM)

Rims 17 × 35

Rock ejectors

Secondary steering (electric)

Tie down eyes

Tow hooks (front)/tow pin (rear)

Vandalism protection locks

773G (Tier 2) OPTIONS

- body heat

- body liner

- body side boards

- cab precleaner

- cat engine brake

- clustered grease fittings

- cold weather packages

- extended life brakes

- fluid fill service center

- hid lights

- mirrors convex

- mirrors heated

- rockford fan attachment for lrc machines

- spare rim

- visibility package meets iso 5006 requirements

- wheel chocks

- work area vision system wavs

MOTEUR

Connecting people and equipment safely

BENEFITS AND FEATURES

Key Features The 773G is solidly constructed for safety.

- Rollover and Falling Object protection is part of the cab structure

- Emergency egress is available through the right-side hinged window

- Laminated glass is used in the front and left side windows

- Ground level engine shutdown for convenience and safety

- A back up alarm gives advance warning of truck movement

Operator Safety The 773G provides operators with full shift comfort and safety features.

- Fully adjustable and suspended seat

- Integrated three point safety belt

- A trainer’s seat with lap belt facilitates on-the-job task training

- Audible warnings signal events, and fluid level monitoring is available from inside the cab

- In some instances, the truck will automatically derate engine power for safety

Job Site Safety

- Speed limiting on the haul is new and more efficient than gear limiting

- Secondary steering in the event of power loss

- Speed limiting during body up operations

A Focus on Personnel The 773G is designed to minimize hazards associated with working on and around this truck.

- Ground level daily check points

- Low effort, integrated access system with hand rails for three points of contact

- Aggressive tread plate on all step areas, and lighting for after dark

- Folding windshield washing platform offers solid footing for cleaning the windshield

Confidence and Control Confident operators will move material quickly, efficiently and profitably.

- Brake design updates increase slope holding capability and include a brake wear indicator

- Wet disc braking for rear wheels; dry disc braking on the front

- Automatic Retarding Control for downhill grades

- New traction control system

Visibility The 773G supports your site safety plan with excellent visibility to the job site.

- Work Area Vision System (WAVS) is a camera system that enhances visibility behind the truck

- Lighting and mirror packages are available to suit your site conditions

Productivity from comfort, confidence, control

BENEFITS AND FEATURES

Comfort The comfort of your crew will contribute to their productivity and awareness on the job.

- Easy, low effort access to the cab

- Ergonomic, intuitive controls

- Left side power window

- Automatic temperature control inside the cab

- Throttle lock convenience for long uphill climbs

- The cab is spacious with window area that supports visibility

- An integrated footrest provides comfort and support

- Sound suppression provides a quieter work environment

- The cab is isolation mounted reducing noise and vibration

- Lighting package options to meet operation needs

- Automotive quality shifting from new APECS transmission controls

Confidence and Control Strong, predictable performance will help your operators achieve the lowest cost per ton.

- Automatic Retarding Control reduces operator effort and controls braking on downhill grades

- Performance and health information at a glance using well lit gauges and the Advisor Message Display

- Steering performance from a design that maintains tire alignment

- Stopping power from fade-resistant brakes - purpose built for off road applications and the loads carried by the 773G

- Traction control is now steering sensitive and uses the service brakes to control wheel slip. The result: faster activation and improved response to wheel slip

- Visibility is excellent with extensive mirror options, large window areas.

Information The Advisor display and VIMS™ software are important reporting tools that help you analyze:

- Productivity, haul road efficiency, operator skill

- Fuel use, cycle times, idle time

- Machine health and events

The benefits are far reaching and economical

BENEFITS AND FEATURES

As you work for a more sustainable business model, the Cat® 773G can contribute in more ways than one.

Fuel and Emissions • There are multiple fuel saving strategies on the 773G, two are economy modes that are adjustable to meet your unique production needs

Sound

- Operator noise is reduced by 50% using sound suppression technology in the cab

- A rubber liner option for truck bodies reduces noise levels for both the operator and spectators

Component Life

- Cat Reman parts are an economical alternative to new

- You can extend tire life using TKPH/TMPH, a feature that calculates tire loading

- Castings and box section frame construction absorb shocks and distribute loads

- A new rear axle housing holds new, robust differential gears that compliment the power and torque increases of the truck

- Hydraulic oil filter life is extended to 1,000 hours under normal conditions

- Autostall enables quick operating temperatures for best performance and life

- Delayed engine shutdown prevents hot shutdowns that can reduce component life

A strategy for lowering your cost per ton

BENEFITS AND FEATURES

The 773G introduces several key fuel conservation features:

- Auto Neutral Idle - as the 773G idles in a forward gear, the transmission will automatically slip in and out of a neutral state to avoid stalling the torque converter and increasing fuel consumption.

- Engine Idle Shutdown - when your G Series truck is in park and idles for more than a preset time, the truck will initiate engine shutdown to conserve fuel. This feature can be time adjusted or turned on or off according to your specific needs.

- Speed Limiting - while you can continue to gear limit your G Series trucks, Caterpillar offers speed limiting that allows the truck to travel at a more fuel efficient engine speed and gear selection.

- Transmission Controls - New APECS transmission controls increase fuel efficiency by maintaining momentum and speed on grade.

Economy Modes

- Standard Economy Mode - G Series has the ability to adjust engine power based on your site, fleet and economic conditions. You can manually control fuel burn by adjusting the power down between 0.5 and 15 percent.

- Adaptive Economy Mode - New for G Series - this economy mode requires a baseline for production from you using the Advisor display. As the truck transits the haul cycle, it is constantly evaluating its ability to meet your baseline in a reduced power setting. Where full power is needed, full power is applied, where reduced power works, reduced power is applied. It’s fully automatic with no special operation required.

Efficient application of power and technology

BENEFITS AND FEATURES

The 773G will haul your material faster and more efficiently with increases in power and new APECS transmission controls.

- A 5% increase in power improves cycle times and grade climbing performance

- New APECS transmission controls carry more torque through the shifts, producing faster cycle times and the possibility of climbing grades in a higher gear

Traction Control G Series introduces benefits to your fleet when running in wet conditions by introducing a more responsive traction controls system.

- The system is steering sensitive to determine slip from high speed turns

- The system engages at slower speeds returning traction sooner

- The system engages sooner in the slip, potentially reducing tire wear

- The system modulates instantly between the two wheel groups for control

- Using the hydraulic service brakes facilitates the instant modulation and responsiveness

Proven components for reliable performance

BENEFITS AND FEATURES

At Caterpillar, we know that our truck is critical to your business, that’s why we use industry leading technology to ensure maximum machine availability and reliability.

Structural Strength The backbone of the 773G is its frame. Our frames are designed for off-road integrity and more than one life cycle. The 773G, with its new power and performance increases, has updated final drive gears and a new rear axle housing to support this new level of work.

- Caterpillar strategically applies castings with box section construction to manage off-road stresses

- A new front frame design increases the approach angle on ramps and grades

- New heavy duty gears compliment the updates in power and torque

- A new robust rear axle housing also supports the truck’s performance

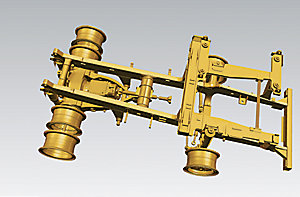

Suspension

- Front struts use our proven king pin design for effective absorption of haul road shocks

- Rear suspension cylinders have been inverted to minimize contamination

Planetary Powershift Transmission with APECS Controls New APECS controls improve performance with the following:

- Torque shift management - allows the truck to power through shift points

- Part throttle shifting - provides an exceptionally smooth ride

- ECPC - electronically controls clutch pressures for long life

Cat C27 ACERT

- 5% more power gives the truck new performance levels and quick haul cycles

- Cat MEUI™ injectors provide high pressure, fine atomization under all load conditions for fuel efficiency and responsiveness

- Low pressure fuel lines from the tank to the engine simplify service

- The C27 is carefully balanced with vibration controls that reduce noise and protect against unnecessary harmonics

- Cooling is provided by either a demand fan or a conventional cooling fan

- Ground level engine shutdown switch for safety

- Excellent high-altitude capability (see specifications for details)

Steering

- The steering linkage is designed to provide feedback to the operator

- The Cat king pin front suspension system maintains steering tolerances and tire alignment

Brake Performance Cat trucks provide powerful, fade-resistant braking for off road applications, and G Series introduces new ways to extend your brake life.

- Rear brakes are wet disc while the front are dry, caliper type

- Slope holding capability benefits from all wheel parking brake actuation

- Brake life can be extended by choosing the optional Cat Engine Brake

- Additional springs in the design reduce wear and increase service life

- A brake wear indicator keeps you informed of maintenance timing

- Extended life brake material is available for extreme applications

For your applications and material types

BENEFITS AND FEATURES

Our truck bodies are engineered to compliment the chassis and built to haul your material for years of trouble-free performance. In fact, Cat truck bodies are designed to let the truck perform at peak efficiency by correctly centering and distributing the load. Outfitting your truck body with a steel or rubber liner may be advisable based on material type and application. If you have questions about body selection or applying liners, your Cat dealer has the tools and knowledge to help you with this decision process.

The Rubber Liner This important factory-installed option will prolong body life in hard rock applications.

- Available for the dual slope and flat floor bodies

- It will reduce shock loading for both the operator and truck

- It absorbs noise, reducing both spectator and operator sound levels

- The rubber liner is not a good option for wet, sticky material

- The rubber liner should not be used with our body heat option

Side Boards In the event that your material is light weight, we offer factory-installed 150 mm (6 in) sideboards to help you achieve rated capacities. You can use our “Body Selection Guide” as a reference for selecting the correct body type and liner package. Cat dealers can order this document using reference number AEXQ0673.

Dual Slope Body If your haul profile includes steep slopes, the dual slope body offers excellent material retention.

- The dual slope has a SAE 2:1 heaped capacity of 35.20 m3 (46 yd3) with a steel liner configuration

- 400 BNH steel on interior surfaces offers excellent wear characteristics

- Material is carried low and centered for stability

- A single 16 mm (0.62 in) steel liner option is available for this body

- A single rubber liner is available for this body

Flat Floor Body If you’re feeding a crusher, the flat floor body is an excellent choice for metering material.

- The flat floor body also offers excellent material retention and stability

- 400 BNH steel is used on internal surfaces for wear protection

- A single steel liner option is available

- A rubber liner is also available for this body

Simple, more cost-effective solutions

BENEFITS AND FEATURES

Service Centers - Electrical Connections This bumper-mounted electrical service center provides the convenience and safety of ground level access to important service tasks.

- Ground level access to VIMS data

- Ground level access to an ET port

- Includes a master disconnect switch

- Engine lockout switch

- Hydraulics lockout switch

- Breaker access

Brake Monitoring G Series introduces updates that will increase the life of your brakes.

- A brake wear indicator is new and standard

- Design improvements are increasing separation forces to lessen wear and increase brake life

Filter Life

- With all new hydraulic system efficiency, your filter life is extended to 1,000 hours

- Cab air filter life can also be extended with the optional cab precleaner.

- Our engine oil filters are improved, and in some cases extending life beyond 500 hours

Service Centers - Fluid Fill You will save both time and money using the optional fluid fill service center.

- Fill and extraction for all fluids in one location

- Key pad indicates existing fluid levels

- Includes all oils, coolant and fuel

- Conveniently located at ground level

- Lighted for night time use

Product Link™ For comprehensive fleet management, Caterpillar offers Product Link solutions. This solution is a combination of machine-mounted hardware and software called Vision Link. You can access fleet information either through cellular or satellite channels. These channels may be restricted and unavailable in some countries. Customers who use Product Link are remotely monitoring machine health and organizing service requirements.