MT4400D AC ELECTRIC DRIVE TRUCK

The Cat MT4400D AC is designed to deliver reliability, serviceability and low owning and operating cost. It is a single sourced truck with a Cat 3516C HD engine and Cat AC Drive System.

SPECIFICATIONS

Nominal Payload Capacity221.0 tonnes

Top Speed - Loaded64.0 km/h

Steer Angle30.0 Degrees

BENEFITS AND FEATURES

power train cat ac electric ...

Gives you more power to the ground for greater productivity.

LEARN MORE

power train engine

Power, reliability and efficiency for your most demanding mining applications.

LEARN MORE

enginepower train integration

Reduced operating costs through electronically coordinated power train components.

LEARN MOREoperating specifications

Nominal Payload Capacity221.0 tonnes

Top Speed - Loaded64.0 km/h

Steer Angle30.0 Degrees

Gross Machine Operating Weight (GMW)392357.0 kg

Turning Circle Diameter30.4 m

engine

Engine ModelCat® 3516C HD

Gross Power - SAE J19951864.0 kW

Bore170.0 mm

Stroke215.0 mm

Displacement78.1 L

weights approximate

Gross Machine Operating Weight (GMW)392357.0 kg

Empty Vehicle Weight171168.0 kg

final drives

Total Reduction Ratio35:1

suspension

Effective Cylinder Stroke - Front304.0 mm

Effective Cylinder Stroke - Rear184.0 mm

Rear Axle Oscillation±5.7°

body hoists

Pump Flow - High Idle900.0 L/min

Relief Valve Setting - Raise17236.0 kPa

Body Raise Time - High Idle22.0 Seconds

Body Power Down - High Idle16.5 Seconds

service refill capacities

Fuel Tank (optional)4922.0 L

Cooling System686.0 L

Crankcase288.0 L

Final Drives, Each129.0 L

Fuel Tank3028.0 L

Hydraulic System (includes tank)1113.0 L

Hydraulic Tank670.0 L

braking system

Electric RetardingBrushless AC Motor

Electric RetardingRadial Grid Design

Electric Retarding - Dynamic Retarding Power3281.0 kW

Front Brakes - Dry Disc - 4 Calipers/Wheel: Disc Diameter1168.0 mm

Rear Oil Cooled Brakes: Brake Surface - Rear155383.0 cm2

Rear Oil Cooled Brakes: Outside Diameter940.0 mm

Rear Oil Cooled Brakes: StandardsJ-ISO 3450 JAN88, ISO 3450:2011

dimensions

Front Canopy Height7341.0 mm

Ground Clearance - Front Axle711.0 mm

Overall Width7950.0 mm

Overall Length14783.0 mm

Wheelbase6401.0 mm

Rear Axle to Tail4318.0 mm

Dump Clearance1524.0 mm

Loading Height - Empty6223.0 mm

Overall Height - Body Raised14326.0 mm

Centerline Front Tire Width6274.0 mm

Inside Body Width7163.0 mm

Rear Axle Clearance914.0 mm

Centerline Rear Dual Tire Width4963.0 mm

Overall Tire Width7605.0 mm

weight distributions approximate

Front Axle - Loaded33.0 %

Rear Axle - Loaded67.0 %

Front Axle - Empty50.0 %

Rear Axle - Empty50.0 %

sound

Sound StandardsHearing protection may be needed when operating with open operator station

cab for extended periods or in a noisy environment

SoundSound Standards

the operator sound pressure level measured according to work cycle procedures specified in iso 6394 and 6396 is 79 dba

Body Capacity - 100% Fill FactorHeaped (SAE 2:1)

125170 m3 163222 yd3

Body Capacity - 100% Fill FactorStruck (SAE)

77135 m3 101176 yd3

AC Drive SystemAlternator

brushless direct mounted dual bearing

AC Drive SystemControls

igbt inverter technology air cooled pressurized cabinet with filtration

AC Drive SystemCooling System

variable speed hydraulic cooling system

AC Drive SystemWheel Motor

rear axle mounted cat ac induction

ROPSROPS Standards

fops falling object protective structure meets iso 34491992

ROPSROPS Standards

rops rollover protective structure meets iso 34711994

BENEFITS AND FEATURES

POWER TRAIN - CAT AC ELECTRIC ...

Gives you more power to the ground for greater productivity.

LEARN MORE

POWER TRAIN - ENGINE

Power, reliability and efficiency for your most demanding mining applications.

LEARN MORE

ENGINE/POWER TRAIN INTEGRATION

Reduced operating costs through electronically coordinated power train components.

LEARN MORE

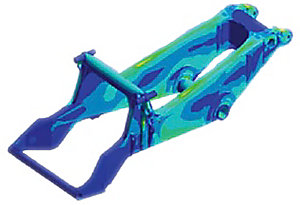

STRUCTURES

Cat structures are known for being the best in the industry for durability and long life.

LEARN MORE

TRUCK BODY SYSTEMS

Caterpillar designed and built for rugged performance and reliability.

LEARN MORE

MT4400D AC STANDARD EQUIPMENT

- electrical

Brushless Alternator, 150 ampere

Ground Level Electrical Isolator

Ground Level Engine Shutdown Switch

Batteries, Size 31 AGM, Quantity 6

Lighting, Signals/Service: - Lights 4 Halogen Headlights (high/low beam) - Lights Rear Dynamic Braking, Service Brakes, Back-up - Lights Service Group - Lights Access Steps - operator environment

Air Conditioner with Climate Control

12 volt DC Power Supply (2)

Cup Holder (2)

Document Holder Compartment

Entertainment Radio Ready: - 20 amp switched/10 amp Memory Converter, Speakers and Wiring Harness

Gauges/Indicators: - Air Cleaner Service Indicator - Brake Drag Warning - Coolant Temperature Gauge - Volt Meter - Fuel Level - Speedometer/Odometer/Hourmeter - Tachometer - Engine Oil Pressure Gauge - Check Engine Indicator - Electric System Fault Indicator - High Hydraulic Temperature - Low Brake Pressure - Low Hydraulic Oil Level - Low Steering Pressure - Stop Engine

Heater/Defroster

Electric Hoist Lever

Horn

Light Dome/Courtesy

Access Light Switch

Engine Start/Stop Switch

Headlight/Tailight Switch

High Low Beam Indicator and Switch

Load Brake Switch

Park Brake Switch

Turn Indicator Lights and Lever

Hand Brake Control

Four Post ROPS Cab, Insulated/Sound Suppressed

Seat, Operator, Air Suspension

Seatbelt, Operator, Three Points, Retractable

Steering Wheel, Tilt, Padded

Sun Visor/Tinted Glass

Windshield Wiper (intermittent) and Washer

Power Windows

Rearview Mirrors (left and right)

Stairway Light Switch - power train

Cat 3516C HD Engine: - Diesel Engine/Turbocharged/Aftercooled - Ground Level Engine Shutdown - Either Starting Aid (automatic) - Elevated Low Idle Control - Automatic Starter Protection - Multi-point Oil Pressure Sensing

Braking System: - Brake Release System for Towing - Oil-cooled, Multi-disc (rear) (service, retarding, parking, secondary) - Front Service/Secondary Caliper Brake - Rear Caliper Disc Park Brake - Automatic Retarding Control - Electric Dynamic Retarding with Blended Low Speed - Engine Overspeed Protection - Extended Life Brake Disc Material

Cat AC Drivetrain: - IGBT Controlled AC Induction Motors - Brushless Traction Generator - Radial Retard Grid with AC Blower Motor

Body-up Reverse Neutralizer

Programmable Top Speed

Rear Axle Continuous Lube/Filtration

Reverse Shift Inhibitor

Directional Shift Management

Neutral Coast Inhibitor

Body-up Shift Inhibitor

Neutral Start Inhibitor - other standard equipment

Radiator Fan Guard

Alternator (24 volt) Belt Guard

Air Conditioner Compressor Belt Guard

Pump Drive Guard

Hydraulic Lubrication Automatic: - 62 L (16.4 gal) Tank - 54.4 kg (120 lb)

Fuel Fast Fill - Quick Charge

Fuel Water Separator

Deck Hand Rails

Reverse Hoist Interlock

Dump Body Lock-up Cable

Muffler (without body heating)

Access Ladder

Automatic Auxiliary Steering (accumulators)

Auxiliary Dumping Connections

Engine Service Ladder (left and right side)

Skid Resistant Deck Top

Air Cleaner Rock Shields

Centralized Terminal Board Locations

Converter 24 volt to 12 volt, 25 amp Capacity

Dry Air Cleaners

Front Wheel Fenders and Mud Guards

Fuel Tank Sight Gauge

Hydraulic Component Box Gauges

Hydraulic Test Ports

Rock Ejectors

Super Large Bore Tire Inflation Values

Clearance Light and Turn Signals

Hinged Dash Panels

Traction Control System

MT4400D AC OPTIONS

- wheel station and rims in 32" or 29"

- body heat exhaust

- conventional body

- high efficiency body

- optima batteries 6

- high intensity discharge hid lighting

- english or metric gauges

- english or metric hub odometer

- payload digital display

- 4920 l 1300 gal fuel tank

- diagonal fixed ladder ground level access on driver’s side

- diagonal powered ladder ground level access on driver’s side

- inverter walkway

- heated mirrors lh and rh

- final drive oil cooler filtration

- standard accumulators and australia certified accumulators

- side profile lighting

- active retarding light indicator

- battery jump start connection

- battery charge receptacle

- fog lights

- camera safety system 1 camera

- camera safety system 3 camera

- hot start for cold weather

- oil pan guard

- rear light guards

- wheel chocks

- portable fire extinguisher

- power supply vacuum

- radiocd player

- murphy gauge

- body

Conventional Body, 127 m3 (166 yd3)

Conventional Body, 143 m3 (187 yd3)

Conventional Body, 119 m3 (156 yd3)

Conventional Body, 110 m3 (144 yd3)

Conventional Body, Canopy Extension to the End of Platform

HE Body with Canopy, 143 m3 (187 yd3) - halogen high mount headlights

- hid high mount headlights

- halogen lh and rh windrowwork lighting

- hid lh and rh windrowwork lighting

- language monitors english spanish italian portuguese dutch norwegian swedish estonian latin lithuanian slovakian slovenian greek roman russian polish czech hungarian icelandic finish danish thai indonesian vietnam malaysian chinese japan korean croat serbian mongolian hebrew turkish arabic

MOTEUR

Gives you more power to the ground for greater productivity.

BENEFITS AND FEATURES

100% Caterpillar Designed and manufactured by Caterpillar, the MT4400D AC is a 221 tonne (244 ton) AC electric drive truck that is single sourced from Caterpillar and supported through the Cat dealer network. The MT4400D power train works seamlessly with the 3516C HD engine to create a smooth ride and offers exceptional safety, serviceability and performance.

Modular Design for Excellent Serviceability The modular design allows for easy removal and installation of components. The engine, traction alternator/generator, motors, inverter, grid, and final drives can be removed independently. The close coupled, dual bearing, traction alternator allows for easy mounting to the 3516C HD engine.

Superior Control Yields Excellent Operator Confidence The Cat AC drive system gives you the best retarding, braking, and control in the industry. Class leading dynamic retarding coupled with blended braking, of the rear wet disc brakes and the front dry brakes, provide the operator with exceptional control and confidence.

High Voltage - Lower Heat The Cat AC drive is a high voltage system (2,600 volts) that operates at relatively low current. The result is lower heat generation, smaller/lighter components, and longer component life.

The Cat AC Electric Drive in Propel The 3516C HD diesel engine drives the close coupled traction alternator through an isolation coupler. The AC power is rectified to a nominal 2,600 volts to form the DC link. The DC link supplies power to the Inverter where IGBT’s convert the DC signal to 3-phase AC to drive the traction motors. Motor output drives the wheels through a Caterpillar double reduction ring output final drive.

Cat AC Electric Drive in Retard During retarding the wheel motors become generators. Motor power is fed back through the DC link. The power is fed to the contactor and chopper circuits and then exhausted through the radial grid. A brushless AC fan blows air across the grid to dissipate the power and control retarding speed.

Traction Alternator No shimming or radial alignment required with the close coupled, dual bearing alternator, resulting in decreased install time. The excitation system is brushless which has longer maintenance intervals than brush type systems.

Inverter The Inverter uses Mitsubishi Electric IGBT Phase Modules to control the rimpull, direction and speed of the truck. Mitsubishi Electric is the leader in IGBT technology.

Traction Motors Each traction motor is a 3-phase AC induction type. The high voltage, low current motor is mounted inside the rear axle box.

Radial Grid The radial design grid sits well back on the deck giving operators excellent visibility to the right side. The grid features the highest retarding power in the industry, better grid life, and is significantly quieter than box grids. The AC electric motor does not require any maintenance, which is a significant savings to the customer over DC motor systems.

Variable Hydraulic Blower The hydraulic drive blower motor offers exceptional cooling, even in extreme environments. The variable hydraulic blower has the ability to provide the required cooling, even while the truck is at idle, compared to direct drive motors that are dependent on engine rpm. The variable blower is better at keeping critical components cool, and thus ensures long component life.

Additional Features

- Anti roll back prevents the machine from moving in a direction opposite the operator’s intent.

- The grid dry function dries the grid quickly in inclement weather.

- Traction Control System (TCS) electronically monitors individual wheel speed and adjusts the torque of each final drive to mitigate the hazard and keep the operator in control.

- Reverse Shift Inhibit ensures reverse propulsion is not applied when the truck is moving forward.

- Cat AC drive system is trolley capable.

Power, reliability and efficiency for your most demanding mining applications.

BENEFITS AND FEATURES

Engine The Cat 3516C HD is a quad turbocharged diesel engine that provides maximum performance in the most demanding mining applications.

Design The 3516C HD is a 16 cylinder design that uses long effective power strokes for more complete fuel combustion and optimum efficiency. The large 78.1 liter displacement, low rpm, and conservative horsepower ratings mean more time on the haul roads and less time in the shop.

Electronic Control Module (ECM) The ECM utilizes advanced engine management software to monitor, control and protect the engine utilizing self-diagnosing electronic sensors. The computerized system senses operating conditions and power requirements and adjusts the engine for peak performance and the most efficient operation at all times.

Cat Data Link Cat Data Link electronically integrates the engine and machine computer system to optimize overall power train performance, increase reliability, maximize component life, and reduce operating costs.

Cat Electronic Technician Provides service technicians with a tool to access stored diagnostic data through the Cat Data Link to simplify problem diagnostics and increase machine availability.

Reduced operating costs through electronically coordinated power train components.

BENEFITS AND FEATURES

Control Software and Integration The integrated controls of the MT4400D AC make the truck simple to operate. They provide:

- Excellent slow speed control for safety within the service areas.

- Excellent throttle response on acceleration to move out of the loading or dump areas.

- Dynamic retarding with blended service brakes, at low speed.

Cat Data Link Caterpillar’s proprietary electronics and controls allow complete machine system integration. The Cat Data Link port provides one location to access all system information for programming function, instead of individual locations for drive system and engine. All computer systems are linked to:

- Optimize power train performance.

- Increase reliability and component life.

- Reduce operating costs.

- Improves fuel efficiency.

Excellent braking control gives operator’s confidence.

BENEFITS AND FEATURES

Industry Leading Dynamic Retarding The radial grid is rated at 3.281 MW (4,400 hp) - allowing you excellent control of the truck speed in long retarding applications. The radial design is light, efficient and quiet.

Brake Design Hydraulic brake actuation system features fully modulated service brakes (foot, or hand operated system), fully modulated secondary brake (foot or hand operated), loading brake for use under the shovel and a spring applied/hydraulic release park brake.

Rear Wet Disc Brakes The wet disc brakes provide the operator with excellent control and confidence in the truck. The Cat oil cooled brakes in the rear wheel assemblies are designed with large discs and plates for reliable and adjustment free operation. They are enclosed and sealed to prevent contamination and provide long life. These oil disc brakes provide exceptional braking at all speeds.

Front Brakes The four calipers/wheel dry front brakes offer excellent stopping capabilities and are very robust.

Blended Braking Full electric retarding effort will be maintained down to a truck speed of 3.2 km/h (2.0 mph). Blended braking of the service brakes (60/40 split rear and front service brakes) occurs between 3.6-4.0 km/h (2.25-2.5 mph) and will be used to completely stop the truck and hold it stationary.

Automatic Retarding Control Operator controlled - (ARC) engages automatically and maintains speed consistently. A simple toggle switch is used to adjust retarding speed.

Anti-Rollback Automatically applies service brakes to prevent the truck from rolling from a stop opposite the intended direction of travel.

Reverse Shift Inhibit Ensures reverse propulsion is not applied when the machine is moving forward.

Park Brake Alarm Park brake alarm alerts the operator if he starts to exit the cab before the park brake has been applied. This feature helps prevent accidental machine movement.

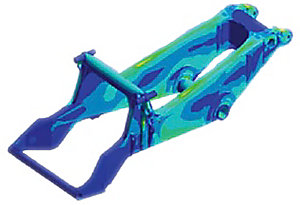

Cat structures are known for being the best in the industry for durability and long life.

BENEFITS AND FEATURES

Straight Rail Frame The MT4400D AC utilizes a straight rail design. The straight rail design eliminates bends and breaks, which are sources of stress concentrations.

- Box Section Construction - The box section construction utilizes Caterpillar proprietary steel specification, which has very low sulfur content and provides excellent welding characteristics, plus outstanding durability.

- Deep Section Main Rails - Deep section main rails, in critical areas of the frame, lower the stress levels resulting in increased frame life.

- Tubular Center Cross Beam - The tubular center cross beam with hoist cylinder and axle box attachment eliminates torsion and eccentric loads associated with conventional designs. The axle box attachment is integrated into the cross member and the bearing surface is replaceable.

Integrated Four Post ROPS Cab Designed to maximize the operator space by deforming the support structure rather than compromise the operator compartment. The transverse mounting beams absorb energy by deflecting around established pivot points, maintaining the integrity of the operator compartment.

Single Beam Front Axle The single beam front axle is designed for load sharing on the beam, resulting in flatter turns and sharing of tire loading for better tire life. This lower structure absorbs the road undulations, giving a better ride and decreasing operator fatigue levels.

Nose Cone Bearing MT4400D AC has a center cross member that incorporates a wraparound spherical axle box nose cone connection. This nose cone attachment features a patented, large two piece bearing that reduces contact pressure to less than 9653 kPa (1,400 psi) allowing for a longer bearing life. The replaceable bearing surface in the axle box attachment is lubricated, sealed, and integrated into the cross member for easy access and maintenance.

Suspension System The design of the suspension system utilizes Nitrogen/Oil suspension cylinders that feature pin to pin mounting allowing for access and change out of components without having to remove the tires.

Durable Design Double shear clevis attachment both top and bottom allows for easy removal and installation of suspension. The Nitrogen/Oil suspension cylinders reduce input loads into the structure for improved fatigue life and better ride.

Caterpillar designed and built for rugged performance and reliability.

BENEFITS AND FEATURES

Cat Bodies Integral to the truck, the body is designed to fit with the chassis and work as part of the truck system. Each body is sized to meet the payload requirements without compromise to vehicle balance, braking or control.

Cat Body Choices Body options include the popular Conventional Body, lightweight High Efficiency Body, and Gateless Coal Body. Liner options fit the body to the application.

- Conventional Body - Based on the mine site evaluation of your mine, the body is sized and configured to meet the specific needs dictated by fragmentation, abrasion, cohesion, and the loading tool. This body achieves an excellent balance of payload and durability (shown in picture).

- High Efficiency (HE) Body - The body is sized and configured to meet the specific needs dictated by fragmentation, abrasion, cohesion, and the loading tool to maximize the payload capability of the truck.

- Gateless Coal Body - Eliminating problematic tail gates - the Gateless Coal Body is intended for dedicated coal haulage.

Keeping your production at peak levels.

BENEFITS AND FEATURES

VIMS™ 3G Monitoring System Provides operator critical health and payload information in real-time to keep the MT4400D AC performing at optimum levels. VIMS is able to monitor information from all vehicle systems. Ten (10) different machine parameters can be viewed at once. Data can be downloaded easily by Service Technicians for troubleshooting, planning and lowering costs.

Advisor Display The Advisor display provides real-time performance, maintenance and diagnostic data to the operator or service technician. A large number of machine parameters can be viewed including temperature, pressure, speed, and payload.

Payload Management Information is available to manage payloads to improve fleet effectiveness and loading tool match. It can help prevent overloading to extend component life and lower operating and maintenance costs.

External Payload Indicators Standard external lights or optional digital display to help loading tool operator reach payload target and minimize overloading.

VIMSpc An Off-board software reporting program that allows your service personnel to download a complete record of machine health and productivity data. Health and payload reports can be generated for more effective machine management, which reduces downtime and lowers operating costs.

VIMS Supervisor Optional software allows your mine personnel to easily manage and interpret VIMS data for optimum fleet management and productivity.

Ergonomically designed for all-day comfort, control and productivity.

BENEFITS AND FEATURES

Operator Environment The Cat MT family cab can accommodate two full size reclining seats, while providing ample storage space behind the seats.

Ergonomic Layout To minimize operator fatigue and maximize productivity, the Cat MT family operator station is ergonomically designed for total machine control in a comfortable, productive and safe environment. Controls, levers, switches and gauges are positioned for ease of use.

Viewing Area Designed for excellent all-around visibility and clear sight lines to the haul road, the large viewing area offers exceptional visibility, allowing the operator to maneuver with confidence for high productivity. The operator environment was designed with curved front glass to provide a 191-degree view. Support pillars have been moved further back to provide a more unobstructed front view. Deck compartments have been positioned to minimize impact on the side field of view.

The most experienced dealer network in the world.

BENEFITS AND FEATURES

Commitment to Meet Your Needs Cat dealer 24/7 support offers solutions, services and products to help you lower costs, enhance productivity, and manage your fleet anywhere in the world. Expert technicians have the knowledge, experience, training, parts and tooling to keep your MT4400D AC running at high availability.

Product Support Caterpillar supports the MT4400D AC with a worldwide network of parts distribution, dealer service centers and technical training facilities. Our global dealer network is ready to meet your support needs around the clock and around the world.

Service Support Cat dealers offer a wide range of service plans to help maximize your uptime and return on your investment, including:

- Preventive Maintenance Programs

- Diagnostic Services such as Scheduled Oil Sampling and Technical Analysis

- Rebuild and Remanufactured Product Options

- Customer Support Agreements

Application Awareness Application and site-specific factors such as material density, loading practices, payload, speed, grade and haul road design and maintenance influence the cost to operate and maintain your haulage fleet. Your Cat dealer can provide help in understanding the effects application factors and operating practices have on maintenance and operating costs. They also offer training to help operators improve productivity, decrease downtime, reduce operating costs and enhance safety.

Reduced maintenance time results in more productivity.

BENEFITS AND FEATURES

Modular Design Major components can be serviced individually with minimal removal and installation time. Work platforms and step/stairs are located in key service areas. The close coupled, dual bearing, generator/alternator is separate from the engine and can be removed without removing the body - wheel motors are separate from final drives.

Ground Level Access Grouped service points (4 filter service groups) allow convenient access to tank levels, filters, drains and S·O·SSM oil sampling ports.

Servicing Ease

- Open engine access with service platforms makes maintenance easy. Traction alternator and inverter platforms allow for easier inspections, troubleshooting, and component change outs.

- Hydraulic cabinet shows critical pressures for all key system in one centralized location.

Separate Hydraulic and Electric Lines Hydraulic lines run inside the left side of the frame, while the electric lines run inside the right side of the frame. This makes servicing and replacement quick and easy.

Designed with safety as the first priority.

BENEFITS AND FEATURES

Product Safety is a Commitment Caterpillar is concerned about your safety. We continue to be the industry leader in proactive development of machines and features that exceed safety standards.

Controls The Cat drive control features anti roll back, traction controls, a park brake warning when exiting the cab, and an automatic retarder that inspires operator confidence.

Isolation The MT4400D AC features a ground level system lockout, VIMS monitoring, and stored energy dissipation at shutdown. These features, and the excellent serviceability of the MT4400D AC, allow your technicians to perform repairs safely and quickly.

Access/Egress Standard 600 mm (24") wide ladders, flat deck, toe kicks, and optional power access stair attachment allows for easy and safe access and egress.

Reduced maintenance time results in more productivity.

BENEFITS AND FEATURES

Sustainability Features The MT4400D AC Mining Truck offers continuous rear axle filtration and extended maintenance intervals which aid in decreasing the amount of waste contributed to our environment.

Remanufacturing Options Cat MT trucks are designed to be rebuilt and deliver a long life. Many MT4400’s have logged over 100,000 hours of frame life. Components are designed to be remanufactured for multiple service lives.

Engines with Advanced Technology Cat engines feature advanced technology components that contribute to better fuel economy and decreased emissions.

12,000 Hour Coolant and Low Oil/Lube Consumption MT4400D AC has exceptionally low oil and lube consumption when compared to the competition. This provides a reduced impact on the environment, lower cost of ownership, and less maintenance time.