797F MINING TRUCK

Whether you’re hauling copper, coal, gold, iron ore or overburden the 797F provides you with the best in class cost per unit of production. Including the improvements in safety, productivity, serviceability and comfort you will see why the 797F is the industry leader of its class. Combine these features with unmatched dealer support and you will see why more mine sites choose Cat Mining Trucks for their production needs.

SPECIFICATIONS

Nominal Payload Capacity363.0 tonnes

Top Speed - Loaded67.6 km/h

Steer Angle40.0 Degrees

BENEFITS AND FEATURES

power train engine

The Cat C175-20 engine provides power, reliability and efficiency for your most demanding ...

LEARN MORE

enginepower train integration

Electronically combined power train components optimize performance.

LEARN MOREoperating specifications

Nominal Payload Capacity363.0 tonnes

Top Speed - Loaded67.6 km/h

Steer Angle40.0 Degrees

Heaped SAE (2:1) Capacity240-267 m3 (314-350 yd3)

Machine Clearance Turning Diameter42.0 m

Turning Circle Clearance Diameter42.0 m

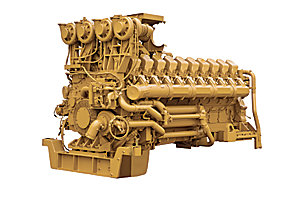

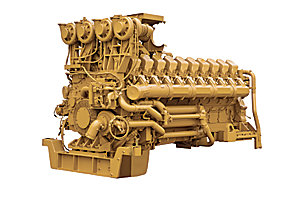

engine

Engine ModelCat C175-20

Gross Power - SAE J19952983.0 kW

Bore175.0 mm

Stroke220.0 mm

Displacement106.0 L

Net Power2828.0 kW

Net Power - SAE J13492828.0 kW

weights approximate

Gross Machine Operating Weight (GMW)623690.0 kg

Body Weight Range41 368-61 235 kg (91,200-135,000 lb)

Chassis Weight Range210 630-219 146 kg (464,359-483,134 lb)

transmission

Forward 111.3 km/h

Forward 215.2 km/h

Forward 320.5 km/h

Forward 427.7 km/h

Forward 537.2 km/h

Forward 650.2 km/h

Forward 767.6 km/h

Reverse11.9 km/h

final drives

Differential Ratio1.276:1

Planetary Ratio16.67:1

Total Reduction Ratio21.26:1

suspension

Effective Cylinder Stroke - Front313.6 mm

Effective Cylinder Stroke - Rear165.1 mm

Rear Axle Oscillation±4.0 degrees

brakes

Number of Discs Per Side - Front10.0

Number of Discs Per Side - Rear15.0

Outside Diameter1067.0 mm

StandardsJ-ISO 3450 JAN88, ISO 3450-1996

Brake Surface330517.0 cm2

body hoists

Pump Flow - High Idle1200.0 L/min

Relief Valve Setting - Raise24200.0 kPa

Body Raise Time - High Idle25.0 Seconds

High Idle Body Lower Time - Float19.0 Seconds

service refill capacities

Fuel Tank (standard)3785.0 L

Cooling System1160.0 L

Crankcase319.0 L

Steering Tank254.0 L

Steering System (Includes Tank)355.0 L

Brake/Hoist Hydraulic Lines830.0 L

Brake/Hoist System (Includes Tank)1600.0 L

Brake/Hoist Tank770.0 L

Differentials1176.0 L

Final Drives, Each185.0 L

Front Wheels, Each61.0 L

Torque Converter Sump303.0 L

Torque Converter/Transmission System (Includes Sump)629.0 L

dimensions

Front Canopy Height - Empty7709.0 mm

Loaded Ground Clearance786.0 mm

Height to Top of ROPS - Empty6526.0 mm

Overall Body Length14802.0 mm

Inside Body Length9976.0 mm

Overall Length15080.0 mm

Wheelbase7195.0 mm

Rear Axle to Tail3944.0 mm

Dump Clearance2017.0 mm

Loading Height - Empty6998.0 mm

Inside Body Depth - Max3363.0 mm

Overall Height - Body Raised15701.0 mm

Centerline Front Tire Width6534.0 mm

Engine Guard Clearance - Full1025.0 mm

Overall Canopy Width9116.0 mm

Outside Body Width9755.0 mm

Inside Body Width8513.0 mm

Rear Axle Clearance - Full947.0 mm

Centerline Rear Dual Tire Width6233.0 mm

Overall Tire Width9529.0 mm

weight distributions approximate

Front Axle - Loaded33.3 %

Rear Axle - Loaded66.7 %

Front Axle - Empty47.2 %

Rear Axle - Empty52.8 %

approximate weights msd ii

Front Axle - Empty47.2 %

Front Axle - Loaded33.3 %

Rear Axle - Empty52.8 %

Rear Axle - Loaded66.7 %

capacity msd ii 100% fill factor

Heaped (SAE 2:1)240-267 m3 (314-350 yd3)

Struck188-213 m3 (246-290 yd3)

tires

Tire59/80R63 - Michelin or Bridgestone

sound

Sound StandardsSAE J919:1995, ANSI/SAE J166:2008, ISO 6394:2008, ISO 6396:2008, ISO 6393:2008, ISO 6395:2008, SAW J88:2006

steering

Steering StandardsSAE J1511 OCT90, ISO 5010:1992

rops

ROPS StandardsISO 3471-1994

BENEFITS AND FEATURES

POWER TRAIN - ENGINE

The Cat C175-20 engine provides power, reliability and efficiency for your most demanding ...

LEARN MORE

ENGINE/POWER TRAIN INTEGRATION

Electronically combined power train components optimize performance.

LEARN MORE

SUSTAINABILITY

A variety of features improve sustainability in areas of decreasing waste, extending ...

LEARN MORE

CUSTOMER SUPPORT

The most experienced dealer network in the world helps keep you up and running.

LEARN MORE

797F STANDARD EQUIPMENT

- electrical

Alarm, back-up

Brushless, alternator, 150 ampere

Batteries, 12V (2) 93 amp-hour

Converter, 12V electrical

Electrical system, 24V, 10, 20 and 25 amp

Battery charge receptacle

Lighting system: - Back-up and hazard lights - Directional signals (front, rear LED) - Front stair access/Service deck - Stop/tail lights (LED) - Engine compartment - VIMS, blue light (LED) - Headlights with lo-hi beam selector - operator environment

Standard cab: - Standard optimized operator seats - Suspension trainer seat - Flip down front visor - Standard side of cab access

Deluxe cab: - Heated and ventilated seats - Suspension trainer seat - Retractable front visor - Rear of cab access and standard side of cab access - Power windows

Deluxe cold weather cab: - Heated and ventilated seats - Suspension trainer seat - Retractable front visor - Rear of cab access and standard side of cab access - Power windows - Heated mirrors

All cab options include the following features: • Air conditioner with automatic climate control • 12V DC power supply (3) • Coat hook • Diagnostic connection port • Dome courtesy light • Entertainment radio ready 5 amp converter, speakers and wiring harness • Gauges/Indicators: - Gauge panel: • Transmission fluid temperature • Brake oil temperature • Engine coolant temperature • Fuel level • Torque converter oil temperature - Electric engine control fault indicator - Electric hour meter - Speedometer - Tachometer - Transmission gear indicator - VIMS message center with advisor • Heater/defroster (11 070 kCal/43,930 Btu) • Horn • Cat Detect System • Storage compartments • Hoist, body control (electric) • ROPS cab, insulated/sound suppressed • Seat, operator, air suspension • Seatbelt, operator, three-points, retractable • Seat, trainer, air suspension • Seatbelt, trainer, two-points, retractable • Stairway and walkway access, 600 mm (23.6 in) • Steering wheel, multi tilt, padded, telescopic • Tinted glass • Window, operator, electric powered • Windshield wiper, intermittent control and washer • Cup holder • Mirrors, right and left - power train

C175-20 Tier 2 emissions compliant engine: - Turbocharging (4)/Air-to-Air Aftercooler (ATAAC) - Air cleaner with precleaner (4) - Ground level engine shutdown - Ether starting aid (automatic) - Elevated low idle control - Crankcase protection - Multi-point oil pressure sensing - Automatic starter protection

Braking system: - Park brake integrated with gear selector - Brake release motor (towing) - Oil-cooled, multi-disc (front and rear) - service, retarding, parking, secondary - Automatic Retarder Control, adjustable - Engine overspeed protection - Extended life brake disc material

Transmission: - 7-speed, automatic powershift with electronic controls (ECPC) - Body-up shift inhibitor - Controlled throttle shifting - Directional shift management - Neutral coast inhibitor - Neutral start switch - Downshift/Reverse shift inhibitor - Individual clutch modulation - Body-up reverse neutralizer - Programmable top speed - Lock-up torque converter

Pre-lubrication/engine

Rear axle continuous lubrication/filtration - other standard equipment

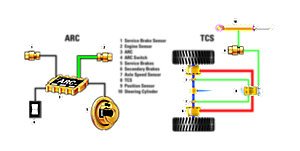

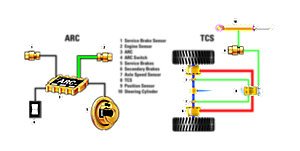

Traction Control System

Auto lubrication system

Aux “buddy” dumping quick connect

Aux steering quick connect (towing)

Driveline guard

Fast fill fuel system

Fuel filter with water separator

Ground level VIMS data port

Ground level battery lockout

Ground level transmission lockout

Ground level engine start lockout

Ground level engine shut-down

High-speed crankcase oil change

Reservoirs (3 separate): - Brake/Hoist, Steering/Fan, Transmission/Converter

Rock ejectors

Supplemental steering (automatic)

Tie-down eyes

Center hitch and tow points (front), tow pin (rear)

Vandalism protection locks

Vital Information Management System (VIMS): - Includes VIMS Payload Monitor with max payload and speed manager

Hydraulic filters, 1,000 hour

S·O·S sample ports

Service points, ground level

Sight level gauges for hydraulic/engine oil - antifreeze

Extended Life Coolant to -35° C (-30° F)

797F OPTIONS

- cat detect system

- cabin air precleaner

- throttle lock

- engine delay shutdown timer

- antifreezecoolant protects to 50° c 58° f

- fuel tank 7570 l2000 gal

- slv grease injectors

- body heat

- rear axle lubrication cooler

- external digital payload display

- oil renewal system

- oil renewal system with 3 day tank

- engine coolant and oil heater for cold weather starts

- road analysis control rac

- portable fire extinguisher

- torque converter guard

- brake wear indicator gauge

- rims wedge

- rim guard

MOTEUR

The Cat C175-20 engine provides power, reliability and efficiency for your most demanding mining applications.

BENEFITS AND FEATURES

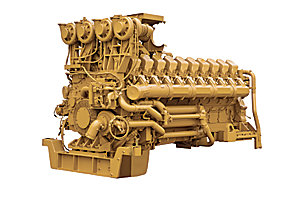

Engine The Cat® C175-20 quad turbocharged and air-to-air aftercooled diesel engine has enhanced power management capability for maximum hauling performance in your most demanding mining applications.

Design The C175-20 is a 20 cylinder, single block, four stroke design that uses long, effective power strokes for optimum efficiency.

EPA Compliant Where applicable, the Cat C175-20 engine is compliant with U.S. Environmental Protection Agency emission requirements.

Long Life High displacement, low rpm rating and conservative power ratings mean more time on the haul roads and less time in the shop.

Cat Common Rail Fuel System The electronically-controlled system senses operating conditions and regulates fuel delivery for optimum fuel efficiency. This precise and flexible fuel system gives the engine the ability to meet emission regulations without sacrificing performance, reliability or durability.

Cooling System The flexible core design of the MESABI radiator means easier serviceability along with long life and high durability. The MESABI radiator comes standard on the 797F.

Starter The tank on the air start system is ground level for easy serviceability.

More power to the ground means greater productivity for you.

BENEFITS AND FEATURES

Mechanical Power Train The Cat mechanical drive power train and powershift transmission provides you unmatched operating efficiency and control on steep grades, in poor underfoot conditions and on haul roads with high rolling resistance.

1 - Transmission The Cat seven speed, planetary power shift transmission is matched with the C175-20 engine to deliver you constant power over a wide range of operating speeds.

- Robust Design - Designed for the higher power of the C175-20 engine, the proven planetary power shift transmission is built tough.

- Long Life - A dedicated oil tank and circuit provides cooler, cleaner oil for maximum performance and longer component life.

Electronic Clutch Pressure Control ECPC provides maximum performance, smooth shifting, long clutch life and a more comfortable ride.

2 - Lock-Up Torque Converter Combines maximum rimpull and cushioned shifting of torque converter drive with the efficiency and performance of direct drive. The lock-up torque converter engages at approximately 8 km/h (5 mph), delivering more power to the wheels.

3 - Final Drives Cat final drives work as a system with the planetary power shift transmission to deliver maximum power to the ground. Built to withstand the forces of high torque and impact loads, double reduction final drives provide high torque multiplication to further reduce drive train stress.

Electronically combined power train components optimize performance.

BENEFITS AND FEATURES

Cat Data Link Reduces your operating costs by electronically integrating the 797’s machine computer systems. This optimizes overall power train performance while increasing reliability and component life.

Body-Up Shift Inhibitor Prevents the transmission from shifting above the pre-programmed gear without the body fully lowered. The machine can move forward but the speed is limited to avoid excessive racking when pulling away from a dump site.

Overspeed Protection The transmission control electronically senses engine conditions and automatically up-shifts one gear to prevent overspeeding.

Programmable Top Gear Transmission top gear maximum can be set using the Cat Electronic Technician service tool to help the operator maintain speed limits.

Downshift Inhibitor Prevents engine overspeeding by keeping the transmission from downshifting until engine speed reaches the downshift point.

Controlled Throttle Shifting Regulates engine rpm during shifting to reduce power train stress and clutch wear by controlling engine speed, torque converter lock-up and transmission clutch engagement for smoother shifts and longer component life.

Reverse Speed Inhibitor Prevents shifts into reverse when forward ground speeds are in excess of 4.8 km/h (3 mph).

Superior braking control lets your operators focus on productivity.

BENEFITS AND FEATURES

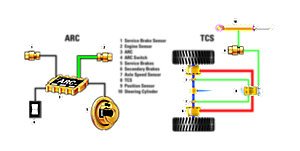

Integrated Braking System The Cat, oil-cooled braking system delivers you reliable performance and control in extreme haul road conditions. The integrated system combines the service, secondary, parking brakes and retarding functions in the same system for optimum braking efficiency that does not burn fuel while retarding.

Oil-Cooled Multiple Disc Brakes Cat four wheel, forced oil-cooled, multiple disc brakes are continuously cooled by water-to-oil heat exchanger for exceptional, non-fading braking and retarding performance.

Brake Design Cat, oil-cooled disc brakes are designed with large discs and plates for reliable, adjustment-free operation and performance. Brakes are completely enclosed and sealed to prevent contamination and reduce maintenance.

Long Life An oil film prevents direct contact between the discs. This design absorbs the braking forces by shearing the oil molecules and carrying heat away to extend brake life.

Parking Brake Oil-cooled, spring-applied, hydraulically released parking brake is applied to all four wheels for superior parking capability on all grades up to 15 percent.

Hydraulic Automatic Retarder Control (ARC) Hydraulically activated, automatic retarder control system electronically controls retarding on grade to maintain optimum engine rpm and brake system performance. ARC is now adjustable in each gear.

Designed and built for rugged performance and reliability.

BENEFITS AND FEATURES

Cat Truck Bodies You have a choice of four MSD II (Mine Specific Design) bodies in conjunction with a configurable liner system to achieve the most efficient hauling solutions at the lowest-cost-per-unit-of-production.

Body Selection The Cat truck body program is committed to providing you the most efficient and highest value body solution for your operation. By studying your mine site and understanding the overall operational requirements and constraints, the body can be configured to meet the unique needs of your application.

MSD II Body The MSD II bodies are the number one choice in the mining industry. The internal body shells are designed and manufactured for superior impact and wear protection. Coupled with the Caterpillar mine specific design process the MSD II bodies optimize the balance of payload and durability.

Truck Body Liners A variety of liner options are available to save weight and extend body life through impact and wear management. The mine specific design system is utilized to provide you with the optimum liner for long life at your mine site.

Superior Cat structures in the 797F give you durability and long life.

BENEFITS AND FEATURES

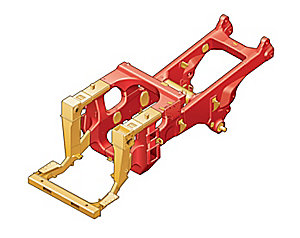

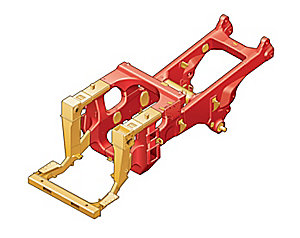

Box Section Design The 797F frame uses a box-section design, incorporating two forgings and 14 castings in high stress areas with deep penetrating and continuous wrap-around welds to resist damage from twisting loads without adding extra weight.

- Steel Structures - Mild steel used throughout frame provides flexibility, durability and resistance to impact loads, even in cold climates and allows for easy field repairs.

- Castings - Castings account for 80 percent of the frame’s weight and are key to providing durability in some of the world’s toughest conditions. The large radii castings are resilient to frame flexing and ensure long life.

Integral Four-Post Cab Resiliently mounted to the frame to reduce vibration and sound, the integral ROPS is designed as an extension of the truck frame.

Suspension System Designed to dissipate haul road and loading impacts for longer frame life and a more comfortable ride.

- Durable Design - Rugged cylinders utilize large diameter bore and low pressure nitrogen/oil design for long life with minimal maintenance.

- Front - Front cylinders with preset caster and camber are mounted on the frame and serve as steering kingpins for a tight turning radius with excellent maneuverability and low maintenance.

- Rear - Rear cylinders allow oscillation and absorb bending and twisting stresses caused by uneven and rough haul roads rather than transmitting them to the main frame.

Four-Bar Link Rear Suspension The four-bar link suspension transfers and supports loads to the frame more efficiently than an A-frame design and allows more service area around the transmission.

Steering System Hydraulic steering control system is designed for exceptional smoothness and precise control. A separate circuit prevents cross contamination for long life.

Ergonomically designed for all-day comfort, control and productivity.

BENEFITS AND FEATURES

Operator Environment You now have the choice to select a cab with the features you desire. There are three choices based on popular arrangements. Available offerings include a Standard Cab, Deluxe Cab or Deluxe Cold Weather Cab.

Ergonomic Layout To minimize operator fatigue and maximize productivity the all new F Series operator station is ergonomically designed for total machine control in a comfortable, productive and safe environment. Controls, levers, switches and gauges are positioned for ease of use.

Viewing Area Designed for excellent all-around visibility and clear sight lines to the haul road, the large viewing area offers exceptional visibility, allowing the operator to maneuver with confidence for high productivity. The air cleaners have been relocated to the front of the truck, allowing the operator increased visibility.

Keeping your production at peak levels.

BENEFITS AND FEATURES

VIMS™ 3G Monitoring System Provides operator critical health and payload information in real-time to keep the 797F performing at optimum levels. VIMS is able to monitor information from all vehicle systems. Ten different machine parameters can be viewed at once. Data can be downloaded easily by service technicians for troubleshooting, planning and lowering costs.

Production and Payload Management Information is available to manage payloads to improve fleet effectiveness and loading tool match and to prevent overloading to help extend component life and lower operating and maintenance costs.

External Payload Indicators Standard external lights or optional digital display to help loading tool operator reach payload target and minimize overloading.

Road Analysis Control Optional system measures frame rack, bias and pitch to help identify haul road problems so they can be repaired. This leads to improved cycle time, component lives and fuel efficiency.

VIMSpc An Off-board software reporting program that allows your service personnel to download a complete record of machine health and productivity data. Health and payload reports can be generated for more effective machine management, which reduces downtime and lowers operating costs.

Advisor Display The Advisor display provides real-time performance, maintenance and diagnostic data to the operator or service technician. A large number of machine parameters can be viewed including temperature, pressure, speed, and payload.

Designed with safety as the first priority.

BENEFITS AND FEATURES

Product Safety Caterpillar is concerned about your safety and has been and continues to be proactive in developing mining machines that meet or exceed safety standards. Safety is an integral part of all machine and system designs.

Access and Egress Improvements for machine level access and egress include a standard 600 mm (24 in) diagonal stairway across the front of the machine. Improvements for ground level access include an optional powered access stairway.

Cat Detect System Knowing what’s around your 797F at all times is important. The Cat Detect system is factory installed as standard equipment on 797F Mining Trucks. The full Cat Detect system, RADAR AND CAMERA, provides both audible and visual indications of detected objects. This system uses a combination of short and medium range radars which surround the machine, along with cameras on each side to allow the operator to confirm the detected object. The cameras supplement the radar alerts and are selectable by touch screen menus through an intuitive interface.

Overload Policy Safety is integral to maintaining the highest productivity in your mining operations. The Caterpillar 10/10/20 Overload Policy assures that steering and braking systems have sufficient capacity to perform, even at 20 percent overload.

Other Safety Features

- Slip resistant surfaces

- 76 mm (3 in) wide orange, three-point operator restraint

- Wide angle mirrors

- Body raised indicator

- Body retaining cables

- Guard rails

- Reverse neutralizer when dumping

- Low interior sound level

Isolation Box Lockout, tagout box mounted on front bumper includes engine shutdown switch, battery lockout, starter lockout and transmission lockout.

SAFETY.CAT.COM™

A variety of features improve sustainability in areas of decreasing waste, extending component life and lowering emissions levels.

BENEFITS AND FEATURES

Sustainability Features The 797F Mining Truck offers continuous rear axle filtration, extended life filters and extended maintenance intervals, which aid in decreasing the amount of waste contributed to our environment.

Engines with Advanced Technology Engines with advanced technology contribute fewer emissions to the environment while maintaining fuel efficiency.

Advanced Surface Technology (AST) Advanced Surface Technology (AST) is a replacement for hard chrome coatings on some steel parts, including suspension and hoist cylinder rods. This technology improves wear resistance and reduces repair time. Chrome has been eliminated to reduce environmental impact.

Fuel Efficiency The engine provides additional retarding by running against compression on downhill hauls. During retarding applications the engine ECM does not inject fuel into the cylinders for exceptional fuel economy.

The most experienced dealer network in the world helps keep you up and running.

BENEFITS AND FEATURES

Commitment Makes the Difference Cat dealers offer a wide range of solutions, services and products that help you lower costs, enhance productivity and manage your operation more efficiently. From the time you select a piece of Cat equipment until the day you trade or sell it, the support you get from your Cat dealer makes the difference.

Dealer Capability Cat dealers provide the level of support you need, on a global scale. Dealer expert technicians have the knowledge, experience, training and tooling necessary to handle your repair and maintenance needs, when and where you need them.

Product Support When Cat products reach the field, they are supported by a worldwide network of parts distribution facilities, dealer service centers and technical training facilities to keep your equipment up and running. Cat customers rely on prompt, dependable parts availability through our global dealer network, ready to meet your needs 24/7.

Service Support Every piece of Cat equipment is designed and built to provide maximum productivity and operating economy throughout its working life. Cat dealers offer a wide range of service plans that will maximize uptime and return on your investment, including:

- Preventive Maintenance Programs

- Diagnostic Programs, such as Scheduled Oil Sampling and Technical Analysis

- Rebuild and Reman Option

- Customer Support Agreements

Application Awareness Operating and maintenance costs are influenced by many application and site-specific factors, such as: material density, loading position, payload, grades, speeds, haul road design and maintenance. Your Cat dealer can provide you with an understanding of the effects application characteristics and operating techniques have on maintenance and operating costs.

Operation Your Cat dealer can arrange training programs to help operator’s improve productivity, decrease downtime, reduce operating costs and enhance safety.

Reduced maintenance time results in more productivity.

BENEFITS AND FEATURES

Servicing Ease Easy access to daily service points simplifies servicing and reduces your time spent on regular maintenance procedures. Enhanced serviceability and long service intervals are designed to increase machine availability and productivity.

In-Frame Access Gives you easy access to major components for easy servicing and removal.

Ground Level Access Grouped ground level points allow you convenient servicing of tanks, filters, drains, batteries, AutoLube system, pressure taps, screens, fluid sight gauges and engine shutdown. Ground level VIMS data port permits easier downloading of information.

AutoLube Automatic lubrication system reduces your maintenance time by automatically lubricating necessary components on a regular basis.

Scheduled Oil Sampling S·O·SSM sampling valves speed sampling and analysis reliability.

Sealed Electrical Connectors Electrical connectors are sealed to lock out dust and moisture. Harnesses are braided for protection. Wires are color-coded for easy diagnosis and repair.