785D MINING TRUCK

The 785D Mining Truck is engineered for performance, designed for comfort, and built to last. Developed specifically for high production mining and construction applications, the 785D Mining Truck keeps material moving at high volume to lower your cost-per-ton. Rugged construction creates a durable machine. Easy maintenance procedures ensure high reliability and long life with low operating costs.

SPECIFICATIONS

Top Speed - Loaded54.8 km/h

Steer Angle36.0 Degrees

Machine Clearance Turning Diameter33.2 m

BENEFITS AND FEATURES

operating specifications

Top Speed - Loaded54.8 km/h

Steer Angle36.0 Degrees

Machine Clearance Turning Diameter33.2 m

Maximum Target Payload143.0 tonnes

Minimum Target Payload131.0 tonnes

Target Payload (Dual Slope)*133.0 tonnes

Turning Diameter - Front29.8 m

engine

Engine ModelCat® 3512C HD

Gross Power - SAE J19951082.0 kW

Rated Power1082.0 kW

Net Power - Cat1005.0 kW

Net Power - ISO 92491005.0 kW

Net Power - 80/1269/EEC1005.0 kW

Torque Rise23.0 %

Bore170.0 mm

Stroke215.0 mm

Displacement58.56 L

Net Power1005.0 kW

Net Power - SAE J13491005.0 kW

weights approximate

Gross Machine Operating Weight (GMW)249476.0 kg

Body Weight Range20 831 - 30 623 kg 45,924 - 67,512 lb

Minimum/Maximum Operating Chassis Weight Range (OCW)83 304 - 84 668 kg 183,654 - 186,661 lb

Minimum/Maximum Operating Chassis Weight Range Empty (EOMW)106 218 - 117 597 kg 234,170 - 259,257 lb

transmission

Forward 112.1 km/h

Forward 216.3 km/h

Forward 322.2 km/h

Forward 429.9 km/h

Forward 540.6 km/h

Forward 654.8 km/h

Reverse11.0 km/h

final drives

Differential Ratio2.10:1

Planetary Ratio10.83:1

Total Reduction Ratio22.75:1

suspension

Effective Cylinder Stroke - Front306.5 mm

Effective Cylinder Stroke - Rear165.0 mm

brakes

Brake Surface - Rear89729.0 cm2

StandardsSAE J1473 OCT90 ISO 3450-1985

Brake Surface - Front61270.0 cm2

body hoists

Pump Flow - High Idle750.0 L/min

Relief Valve Setting - Raise17238.0 kPa

Body Raise Time - High Idle15.2 Seconds

Body Lower Time - Float16.2 Seconds

Body Power Down - High Idle15.9 Seconds

Body Lower Time - High Idle15.9 Seconds

service refill capacities

Fuel Tank (standard)1893.0 L

Cooling System379.0 L

Crankcase204.0 L

Steering Tank90.0 L

Steering System (Includes Tank)117.0 L

Brake/Hoist Hydraulic Tank337.0 L

Brake/Hoist System (Includes Tank)641.0 L

Differential and Final Drives436.0 L

Torque Converter/Transmission System (Includes Sump)248.0 L

body x

Body Weight25160.0 kg

Heaped SAE (2:1)85.0 m3

weight distributions approximate

Front Axle - Empty*45-46%

Front Axle - Loaded (Target)33.0 %

Rear Axle - Empty*54-55%

Rear Axle - Loaded (Target)67.0 %

tires

Standard Tires33.00-R51 (E3

e4

SoundSound Standards

ansisae j1166 may90 sae j88 apr95

SteeringSteering Standards

sae j1511 oct90 iso 50101992

Body - Dual SlopeBody Weight

222950 kg

Body - Dual SlopeHeaped SAE (2:1)

780 m3

ROPSROPS Standards

sae j1040 apr88 iso 34711994

BENEFITS AND FEATURES

STRUCTURES/SUSPENSION/STEERING

Rugged Cat designs are the backbone of the 785D mining truck’s durability.

LEARN MORE

OPERATOR’S STATION

Designed for operator safety and comfort, superior control and high productivity.

LEARN MORE

CAT BRAKE SYSTEM

Superior control gives the operator confidence to focus on productivity.

LEARN MORE

SUSTAINABILITY

A variety of features improve sustainability in areas of decreasing waste, extending ...

LEARN MORE

785D STANDARD EQUIPMENT

- electrical

Alarm, Back-up

Alternator (105 A)

Batteries, 93Ah, Low-maintenance, 12V (2)

Converter, 12V electrical

Electrical System, 24V, 15A

Lighting System - operator environment

Air Conditioner

Ashtray/cigarette lighter

Coat hook

Diagnostic connection port

Dome courtesy light

Entertainment radio ready

Gauges/Indicators

Heater/defroster

Horn

Hoist body control, electric

Integrated Object Detection System

ROPS cab insulated/sound suppressed

Storage compartment

Seatbelt, 75 mm (3 in), retractable

Steering wheel, tilt, padded, telescopic

Sun visor

Tinted glass

Window, electric powered, operator

Windshield wiper, intermittent control and washer - power train

Cat 3512C HD-EUI diesel engine

Braking System

Transmission - other standard equipment

Air Line Dryer (2)

Body Mounting Group

Auto lubrication system (Lincoln)

Dumping, Auxiliary Quick Connect for “Buddy Dumping”

Steering, Auxiliary Quick Connect for Towing

Continuous rear axle filtration

Diagonal stairway, 600 mm (24 in)

Driveline Operator Safety Guard

Fast-fill Fuel System

VIMS Dataport

Battery Disconnect

High speed crankcase oil change

Reservoirs (Separate)

S·O·SSM sample ports

Supplemental steering (automatic)

Tie Down Eyes

Tow Hooks, Front

Traction Control System

Vandalism Protection Locks

Vital Information Management System (VIMS) includes:

785D OPTIONS

- bodies

Body, X

MSD II (Mine Specific Design)

Dual Slope

Custom Body Options - body extensions

Tail

Wrap around - liners

Full-length liner

Tail extension wrap-around - operator environment

Footrest, operator

Hose, cab clean-out

Vacuum, cab clean-out - power train

Pre-lube, engine

Oil renewal system

Oil cooler, rear axle - cold weather

Starting, Cold Weather - tires and rims

Spare rims - information management

Control, Road Analysis (RAC) - service center

Service Center, Wiggins - miscellaneous

Fire extinguisher, portable

Hub Odometer, Kilometers

Hub Odometer, Miles

Wheel Chocks

Heater, Diesel fuel

MOTEUR

The Cat® 3512C HD engine delivers high power and reliability.

BENEFITS AND FEATURES

Design The 3512C HD is a 12-cylinder, four-stroke design that uses long, effective power strokes for more complete fuel combustion and optimum fuel efficiency.

EPA Compliant Where applicable, the 3512C engine is compliant with U.S. Environmental Protection Agency emission requirements.

Altitude Compensation Designed for maximum operating efficiencies at altitudes under 4267 m (14,000 ft).

High Torque Rise The 23 percent net torque rise provides unequalled lugging force during acceleration, on steep grades and in rough underfoot conditions. Torque rise effectively matches transmission shift points for maximum efficiency and fast cycle times.

Enhanced Life High displacement, low rpm rating and conservative horsepower ratings mean more time on the haul roads and less time in the shop.

Oil Renewal System Optional oil renewal system extends engine oil change intervals from 500 hours to 4,000 hours or more to increase machine availability and reduce costs.

Vibratory Plate Compactors Computerized system electronically protects the engine during cold starts, high altitude operation, air filter plugging, high exhaust temperature and engine overspeed (ARC). Optional Engine Pre-Lubrication builds up oil pressure before cranking providing additional wear protection.

Fuel Efficiency The engine provides additional retarding by running against compression on downhill hauls. During retarding applications the engine ECM does not inject fuel into the cylinders for exceptional fuel economy.

Unmatched operating efficiency in all mining conditions.

BENEFITS AND FEATURES

Mechanical Power Train The Cat mechanical drive power train and power shift transmission provides unmatched operating efficiency and control on steep grades, in poor underfoot conditions, and on haul roads with high rolling resistance.

1) Transmission The Cat six-speed planetary power shift transmission is matched with the direct-injection 3512C engine to deliver constant power over a wide range of operating speeds.

Robust Design Designed to efficiently apply the higher horsepower of the 3512C engine, the proven planetary power shift transmission is built tough for long life between overhauls.

Transmission Chassis Control (TCC) TCC uses electronically transferred engine rpm data to execute shifts at preset points for optimum performance, efficiency and clutch life.

2) Lock-Up Torque Converter Combines maximum rimpull and cushioned shifting of torque converter drive with the efficiency and performance of direct drive. Engages at approximately 8 km/h (5 mph), delivering more power to the wheels.

3) Final Drives Cat final drives work as a system with the planetary power shift transmission to deliver maximum power to the ground. Built to withstand the forces of high torque and impact loads, double reduction final drives provide high torque multiplication to further reduce drive train stress.

Wheels and Rims Cast rear wheels and Cat center-mount rims are mounted using studs to minimize installation, maintenance and maximize durability.

Rear Axle Filtration A new pump drive system provides continuous rear axle filtration. Benefits include cleaner oil, less downtime and improved component life.

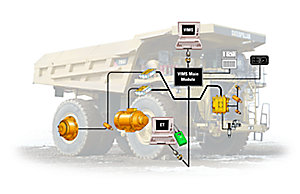

Electronically optimizes overall truck performance.

BENEFITS AND FEATURES

Cat Data Link Electronically integrates machine computer systems to optimize overall power train performance, increase reliability and component life, and reduce operating costs.

Electronic Technician (Cat ET) Cat ET service tool provides service technicians with easy access to stored diagnostic data through the Cat Data Link to simplify problem diagnosis and increase machine availability.

Integrated Braking Control (IBC) IBC integrates Automatic Retarder Control and Traction Control into one system for optimum performance and efficiency.

Body-up Reverse Neutralizer Automatically shifts the transmission to neutral if the hoist lever is activated while transmission is shifted in reverse.

Supplemental Steering Supplemental Steering system uses pressure accumulators and allows up to three 90-degree turns in case of engine failure.

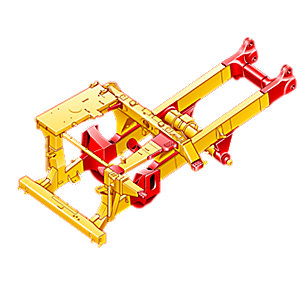

Rugged Cat designs are the backbone of the 785D mining truck’s durability.

BENEFITS AND FEATURES

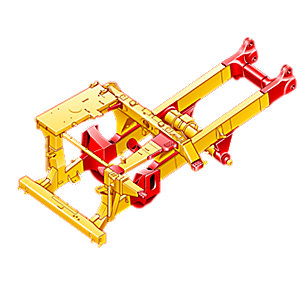

Box-Section Design The 785D frame uses a box-section design, incorporating two forgings and 24 castings in high stress areas with deep penetrating and continuous wrap-around welds to resist damage from twisting loads without adding extra weight.

Serviceability The open box-section frame design allows easy access to power train components, reducing overall removal and installation time, and lowering overall repair costs. The raised and pinned body allows excellent access to the transmission.

Steel Structures Mild steel used throughout frame provides flexibility, durability and resistance to impact loads, even in cold climates, and allows for easy field repairs.

Integral Four-Post ROPS Cab Resiliently mounted to the main frame to reduce vibration and sound, the integral ROPS is designed as an extension of the truck frame. The ROPS/FOPS structure provides “five-sided protection” for the operator and instructor.

Suspension System Designed to dissipate haul road and loading impacts for longer frame life and a more comfortable ride.

Steering System Hydraulic steering control system is designed for exceptional smoothness and precise control. A separate circuit prevents cross contamination for long life.

Supplemental Steering Supplemental steering system uses pressure accumulators and allows up to three 90-degree turns in case of engine failure.

Cylinders Four independent self-contained, oil pneumatic, variable rebound suspension cylinders are designed to absorb shocks in the most severe applications.

Durable Design Rugged cylinders utilize large diameter bore and low pressure nitrogen/oil design for long life with minimal maintenance.

Designed for operator safety and comfort, superior control and high productivity.

BENEFITS AND FEATURES

Enhanced Operator Visibility Through the use of the fully Integrated Object Detection System, RADAR AND CAMERA, the operator can receive both audible and visual indications of detected objects.

Ergonomic Layout The 785D operator station is ergonomically designed for total machine control in a comfortable, productive and safe environment. All controls, levers, switches and gauges are positioned to maximize productivity and minimize operator fatigue.

Quiet Cab Integral, sound-suppressed ROPS/FOPS cab is resiliently mounted to the mainframe to isolate the operator from sound and vibration for a quiet, secure and comfortable ride.

Viewing Area Designed for excellent all-around visibility and clear sight lines to the haul road, the large viewing area enables the operator to maneuver with confidence for high productivity. 1) Air Suspension Seat with Three-Point Operator Restraint 2) Hoist Lever 3) Secondary Brake Pedal 4) Monitoring System 5) Steering Column 6) Transmission Console 7) Parking Brake Reset Valve 8) Storage Compartment 9) Trainer Seat 10) Operator Window 11) Operator Controls 12) Heating/Air Conditioning

Radio Ready The operator’s station comes ready with power ports, speakers, antenna, and electrical connections to facilitate trouble-free radio installation. Consult your dealer for the complete line of available Cat radio options including satellite radio.

Superior control gives the operator confidence to focus on productivity.

BENEFITS AND FEATURES

Integrated Braking System The Cat oil-cooled braking system delivers reliable performance and superior control in the most extreme haul road conditions. Automatic brake modulation offers a smoother ride and better control in slippery conditions, allowing the operator to concentrate on driving. The two piston design system combines the service, secondary, parking brake and retarding functions in the same robust system for optimum braking efficiency.

Four Corner Retarding Four corner retarding with 60/40 percent split (rear/front) in braking effort provides superior control in slippery conditions. Balanced front to rear brake torque provides exceptional braking performance and minimizes wheel lock-up, especially during retarding.

Oil-Cooled Multiple Disc Brakes Cat four-wheel, forced oil-cooled, multiple disc service brakes are continuously cooled by water-to-oil heat exchangers for exceptional, non-fade braking and retarding performance.

Extended Life Disc Brakes Cat oil-cooled disc brakes are designed with large discs and plates for reliable, adjustment-free operation and performance. Brakes are completely enclosed and sealed to prevent contamination and reduce maintenance. Additionally, this machine features new extended life friction material that is now standard on this model. The friction material has double the wear life of standard brakes and is twice as resistant to glazing resulting in more consistent braking power with less noise.

Pistons The primary piston hydraulically actuates both service and retarding functions. The secondary piston is spring-applied and held in the disengaged position by hydraulic pressure. If hydraulic system pressure drops below a specified level, the spring-applied secondary piston automatically applies the brakes.

Parking Brake The superior parking brake function on this truck is provided by the oil-cooled, spring-applied, hydraulically-released service brakes at all four wheels. This reliable and durable parking brake will hold a truck carrying a rated load on any grade up to 15 percent.

Caterpillar designed and built for the toughest mining applications.

BENEFITS AND FEATURES

Cat Truck Bodies Matching the truck body to the application is a critical part of achieving the best value from your 785D. Caterpillar offers a variety of application specific body options that yield a payload ranging from 131 to 143 metric tons (144 to 157 tons). The Caterpillar exclusive 10/10/20 payload guidelines help achieve a balance of excellent payload with safe operation.

Body Options 1) Cat “X” Body - The X body is a heavy duty body configured with a variety of liner options to meet site specific requirements of a mine. Like the Dual Slope - the X body is designed for durability across a range of harsh applications. 2) Mine Specific Body (MSD II) - For mature mines with good operational and maintenance practices, the lighter weight MSD II (Mine Specific Design) body is available in several sizes. It is a customer/site specific body that is designed to maximize performance. The MSD II is designed to maximize payload, provide good durability and can be configured with a variety of liner options to meet the specific requirements of the mine. 3) Gateless Coal Body - This specialized high volume body, available in several sizes, is targeted at dedicated coal haulage applications with minimal impact. The kicked up floor design eliminates the tailgate and gives the volume required to meet target payload. 4) Dual Slope Body - The original standard body, the Dual Slope body, provides excellent load retention, maintains a low center of gravity with optimum load distribution, reduces shock loading and is available in lined and unlined configurations. The Dual Slope body is intended for tough applications including greenfield sites and contracting mines.

Custom Body Options A variety of options including tail extensions, sideboards, tumble bars, rock boxes and rock shedders are available to maintain rated payload, reduce spillage and improve hauling efficiencies.

Vital machine health and payload data keeps the 785D performing.

BENEFITS AND FEATURES

VIMS® Monitoring System The Caterpillar designed machine monitoring system provides critical machine health and payload information to the operator and service personnel. With the system monitoring and the advanced diagnostic ability, VIMS simplifies troubleshooting and reduces downtime by identifying abnormal conditions before they cause damage. VIMS also stores machine data to help manage production and utilize the efficiency Preventative Maintenance.

Production Management Production Management enhances truck/loading tool effectiveness, improves fleet productivity and helps extend the life of truck frames, tires, rims and power train components, while lowering operating and maintenance cost.

Payload Management Max Payload Speed Manager is a feature that aids in managing the Caterpillar 10/10/20 Overload Policy. Based on target payload weight and overload settings, the VIMS system logs and warns the operator when the truck reaches overload after second gear reweigh. The truck will be limited to second gear at 1,750 rpm, and the automatic retarder speed setting is reduced to 1,750 rpm until the load is dumped.

Road Analysis Control (RAC) Optional system monitors haul road conditions by measuring frame rack and pitch to improve haul road maintenance, cycle times, tire life and fuel efficiency.

VIMS-PC VIMS-PC, the off-board reporting software program, allows service personnel to download a complete record of machine health and productivity data to a laptop computer for diagnosis and analysis. Easy-to-use software enables service technicians and mine management to generate health and payload reports for more effective machine management.

VIMS Supervisor Optional software allows mine management to easily manage and interpret VIMS data for optimum fleet management and productivity.

Machine Management Service technicians or mine personnel can download data and generate reports. Data can be used to improve effectiveness of scheduled maintenance programs, maximize component life, improve machine availability, and lower operating costs.

Gauge Cluster Conveniently located gauge cluster maintains a constant display of vital machine functions.

Cat mining machines and systems: Safety is priority one.

BENEFITS AND FEATURES

Product Safety Caterpillar has been and continues to be proactive in developing mining machines that meet or exceed safety standards. Safety is an integral part of all machine and system designs.

Access and Egress Improvements for machine level access and egress include a standard 600 mm (24 in) diagonal stairway across the front of the machine. Improvements for ground level access include an optional powered access stairway.

Integrated Object Detection Systems Object Detection Systems are factory installed as standard equipment on 785D mining trucks. The fully Integrated Object Detection System, RADAR AND CAMERA, provides both audible and visual indications of detected objects. This system uses a combination of short and medium range radars which surround the machine, along with cameras on each side to allow the operator to confirm the detected object. The cameras supplement the radar alerts and are selectable by touch screen menus through an intuitive interface.

Overload Policy Adherence to the Caterpillar 10/10/20 Overload Policy assures that steering and braking systems have sufficient capacity to perform.

Standard Safety Features Slip resistant surfaces, retractable, seat/shoulder belts with three-point operator restraint, wide-angle mirrors, body raised indicator, body retaining cable, guard rails, reverse neutralizer when dumping, low interior sound level, secondary steering system, ground level access shutoff switches.

SAFETY.CAT.COM™

A variety of features improve sustainability in areas of decreasing waste, extending component life and lowering emissions levels.

BENEFITS AND FEATURES

Sustainabilty Features The 785D Mining Truck offers oil renewal systems, continuous rear axle filtration, extended life filters and extended maintenance intervals which aid in decreasing the amount of waste contributed to our environment.

Engines with Advanced Technology Engines with advanced technology contribute less emissions to the environment while maintaining fuel efficiency.

Advanced Surface Technology (AST) Advanced Surface Technology (AST) is a replacement for hard chrome coatings on some steel parts, including suspension and hoist cylinder rods. This technology improves wear resistance and reduces repair time. Chrome has been eliminated to reduce environmental impact.

Fuel Efficiency The engine provides additional retarding by running against compression on downhill hauls. During retarding applications the engine ECM does not inject fuel into the cylinders for exceptional fuel economy.

Less time spent on maintenance means more time on the haul roads.

BENEFITS AND FEATURES

Servicing Ease Easy access to daily service points simplifies servicing and reduces time spent on regular maintenance procedures. Enhanced serviceability and 500-hour service intervals are designed to increase machine availability and productivity.

Maintenance Platform Provides access to engine, air filters, steering hydraulic tank and battery compartment.

In-Frame Access Permits easy access to major components for easy servicing and removal.

Ground-Level Access Allows convenient servicing to tanks, filters, drains, and engine shutdown. Ground-level VIMS data port permits easier downloading of information.

Autolube Automatic lubrication system reduces maintenance time by automatically lubricating necessary components on a regular basis.

Fast Fill Service Center Optional service center reduces daily maintenance times with clustered fast fill connections for steering oil, transmission oil, engine oil and coolant.

Pressure Test Points and S•O•SSM Ports Sample points and ports yield representative samples to monitor critical machine systems.

Sealed Electrical Connectors Electrical connectors are sealed to lock out dust and moisture. Harnesses are braided for protection. Wires are color coded for easy diagnosis and repair.

Fast Fill Fuel Provides a receiver at the fuel tank to accept most 567 liters per minute/150 gallons per minute fueling systems.

Air Filters Radial seal air filters are easy to change, reducing time required for air filter maintenance.

Cat dealers have what it takes to keep mining haul trucks productive.

BENEFITS AND FEATURES

Commitment Makes the Difference Support goes far beyond parts and service. From the time you select a piece of Cat equipment until the day you rebuild, trade or sell it, the support you get from your Cat dealer makes the difference that counts.

Dealer Capability Dealer expert technicians have the knowledge, experience, training and tooling necessary to handle your repair and maintenance needs, when and where you need them.

Product Support and Service Support Supported by a worldwide network of parts distribution facilities, dealer service centers and technical training facilities, Cat dealers can maximize your uptime. With a tailored service plan, your dealer can help you get the most return on your investment.

Training Your Cat dealer can arrange training programs to help operators improve productivity, decrease downtime, reduce operating costs, enhance safety, and improve return on the investment you make in Cat products.

Technology Products Cat dealers offer a range of advanced technology products such as VIMS monitoring system and MineStar™ information management system. These products include radio data communications, machine monitoring and diagnostics, fleet management, and haul road maintenance software - all designed to improve fleet efficiency, increase productivity, and lower costs.

www.cat.com For more complete information on Cat products, dealer services, and industry solutions, visit us on the web at www.cat.com.