M324D2 MH WHEEL MATERIAL HANDLER

We know that when it comes to material handling equipment, your success depends on high productivity and dependable performance. The M324D2 MH offers a great compromise between the agility, versatility and performance of a wheeled excavator and the stability, efficiency and power needed to cope with harsh environments and applications of industrial, scrap, waste recycling and bulk handling operations, which call for safe, quality and reliable products, while generating a low operating cost to the owner. The new M324D2 MH is here to help you take on the wide variety of challenges you face every day, more easily and with more pleasure. Commitment from the Ground Up.

SPECIFICATIONS

Engine ModelCat® C7.1 ACERT™

EmissionsMeets China Nonroad III, UN/ECE R96 Stage IIIA emission standards

EngineRatings

BENEFITS AND FEATURES

engine

Engine ModelCat® C7.1 ACERT™

EmissionsMeets China Nonroad III, UN/ECE R96 Stage IIIA emission standards

us epa tier 3eu stage iiia equivalent emission standards

EngineRatings

2000 rpm

WeightsOperating Weight

23 57024 890 kg 5196354873 lb

WeightsOperating Weight with Work Tool

23 570 kg to 26 660 kg 51963 lb to 58775 lb

WeightsMH Boom – MH Undercarriage, Straight Stick

25600 kg

WeightsMH Boom – MH Undercarriage, Drop Nose Stick

25300 kg

Hydraulic SystemTank Capacity

225 l

Hydraulic SystemSystem

405 l

Swing MechanismSwing Torque

53 kn·m

Swing MechanismSwing Speed

9 rpm

Service Refill CapacitiesFuel Tank Capacity

385 l

Service Refill CapacitiesCooling

37 l

Service Refill CapacitiesEngine Crankcase

15 l

Service Refill CapacitiesRear Axle Housing (Differential)

14 l

UndercarriageMaximum Steering Angle

35°

UndercarriageOscillation Axle Angle

±5°

EnginePower – ISO 14396

1288 kw

EnginePower – ISO 9249 @ 2,000 rpm

122 kw

EnginePower – 80/1269/EEC

EngineBore

105 mm

EngineStroke

135 mm

EngineDisplacement

701 l

EngineMaximum Torque at 1,400 rpm

868 n·m

EngineCylinders

6

Working RangesMaximum Reach (stick pin)

12480 mm

Working RangesMaximum Height (stick pin)

13300 mm

DriveMaximum Travel Speed

25 kmh

TransmissionForward/Reverse – 1st Gear

7 kmh

TransmissionForward/Reverse – 2nd Gear

25 kmh

TransmissionCreeper Speed – 1st Gear

3 kmh

TransmissionCreeper Speed – 2nd Gear

9 kmh

TransmissionDrawbar Pull

124 kn

TransmissionMaximum Gradeability

56%

UndercarriageGround Clearance

360 mm

UndercarriageMinimum Turning Radius: SA Undercarriage with Dual Pneumatic Tires – Outside of Tire

6800 mm

UndercarriageMinimum Turning Radius: SA Undercarriage with Dual Pneumatic Tires – End of One-Piece Boom

9300 mm

Service Refill CapacitiesFront Steering Axle (Differential)

11 l

Service Refill CapacitiesFinal Drive

25 l

Service Refill CapacitiesPowershift Transmission

WeightsMH Boom – Standard Undercarriage, Straight Stick

25250 kg

WeightsOne-Piece Boom – Front Dozer, Rear Outriggers, 2.5 m Stick

24520 kg

WeightsSticks – Digging Medium (2500 mm)

950 kg

WeightsSticks – Digging Long (2900 mm)

1025 kg

WeightsSticks – Straight (4800 mm)

1380 kg

WeightsSticks – Drop Nose (4900 mm)

940 kg

WeightsSticks – Drop Nose (5900 mm)

1100 kg

WeightsMH Push Blade

675 kg

WeightsDozer Blade

850 kg

WeightsSolid Tires (delta vs. standard tires)

950 kg

WeightsCounterweight

5400 kg

Hydraulic SystemMaximum Pressure: Implement Circuit – Normal

35000 kpa

Hydraulic SystemMaximum Pressure: Implement Circuit – Heavy Lift

37500 kpa

Hydraulic SystemMaximum Pressure: Implement Circuit – Travel Circuit

35000 kpa

Hydraulic SystemMaximum Pressure: Auxiliary Circuit – High Pressure

Hydraulic SystemMaximum Pressure: Auxiliary Circuit – Medium Pressure

20500 kpa

Hydraulic SystemMaximum Pressure: Auxiliary Circuit – Swing Mechanism

34000 kpa

Hydraulic SystemMaximum Flow: Implement/Travel Circuit

350 lmin

Hydraulic SystemMaximum Flow: Auxiliary Circuit – High Pressure

250 lmin

Hydraulic SystemMaximum Flow: Auxiliary Circuit – Medium Pressure

40 lmin

Hydraulic SystemMaximum Flow: Swing Mechanism

112 lmin

Tire OptionsOption

100020 dual solid rubber

Tire OptionsOption

110020 dual pneumatic

Push BladeBlade Type

radial

Push BladeBlade Height

920 mm

Push BladeBlade Width

2990 mm

SustainabilityEngine Emission Standards

meets china nonroad iii unece r96 stage iiia emission standards

U.S. EPA Tier 3/EU Stage IIIA equivalent emission standardsSustainability

fluids optional – cat bio hydo™ advanced

Readily biodegradable, EU Flower eco-label certifiedSustainability

fluids optional – biodiesel up to b20

Meets EN 14214 or ASTM D6751 with EN590 or ASTM D975 standard mineral diesel fuelsSustainability

vibration levels maximum handarm – iso 53492001

Sustainability

vibration levels maximum whole body – isotr 253982006

Sustainability

seat transmissibility factor – iso 7096 2000spectral class em5

Standards

ops

Meets OPS criteria 2006/42/ECStandards

fops

FOPS (Falling Object Protective Structure) meets FOPS criteria ISO 10262:1998 and SAE J1356:2008Standards

cabsound levels

Meets appropriate standards as listed in "Sound Levels"Sound Levels

operator sound – 200014ec gb 167102010

71 dB(A)Sound Levels

exterior sound – 200014ec gb 167102010

103 dB(A)

BENEFITS AND FEATURES

M324D2 MH STANDARD EQUIPMENT

- electrical

Alternator, 85A

Heavy-duty maintenance free batteries

Lights: – Boom working light – Roading lights two front – Roading lights two rear, LED – Working lights, cab mounted (front and rear) – Cab interior light

Main shut-off switch

Signal/warning horn - engine

Automatic engine speed control

Automatic starting aid

Cat C7.1 with ACERT Technology

Meets China Nonroad III, UN/ECE R96 Stage IIIA emission standards, and U.S. EPA Tier 3/EU Stage IIIA equivalent emission standards

Fuel/water separator with level indicator

High ambient cooling 52° C - hydraulics

Control circuits (standard and optional, depending on boom/stick/linkage choice): – Two-way, medium pressure circuit, for rotating or tilting of work tools

Heavy lift mode

Load-sensing plus hydraulic system

Manual work modes (economy, power)

Separate swing pump

Auxiliary controls and lines

Boom and stick lowering control devices - operator station

Adjustable armrests

Adjustable hydraulic sensitivity

Air conditioner, heater and defroster with automatic climate control

Beverage cup/can holder

Bolt-on top/front guards capability

Bottle holder

Bottom mounted parallel wiping system, covering upper and lower windshield glass

Camera mounted on counterweight displays through cab monitor

Coat hook

Floor mat, washable, with storage compartment

Fully adjustable suspension seat, including headrest

Hydraulic cab riser, 2400 mm rising

Instrument panel and gauges, full graphic and color display: – Information and warning messages in local language – Gauges for fuel level, engine coolant and hydraulic oil temperature – Filters/fluids change interval – Indicators for headlights, turning signal, low fuel, engine dial setting – Clock with 10-day backup battery

Laminated front windshield

Left side console, tiltable, with lock out for all controls

Literature compartment behind seat

Literature holder in right console

Mobile phone holder

Parking brake

Positive filtered ventilation

Power supply, 12V-7A

Rear window, emergency exit

Retractable seat belt

Skylight

Sliding door windows

Steering column, adjustable angle

Storage area suitable for a lunch box

Sunshade for windshield and skylight - undercarriage

Heavy-duty axles, advanced travel motor, adjustable braking force

Oscillating front axle, with remote greasing

Tool boxes, left and right, in undercarriage

Two-speed hydrostatic transmission

Tires, 11.00-20 16 PR, dual pneumatic, with spacer rings - other equipment

Automatic swing brake

Counterweight, 5400 kg

Mirrors, frame and cab

Product Link

S·O·S Quick Sampling valves for engine oil, hydraulic oil and coolant

M324D2 MH OPTIONS

- auxiliary controls and lines

Auxiliary boom and stick lines

Control circuits (standard and optional, depending on boom/stick/linkage choice): – Tool control/multi function:- One/two-way high pressure for hammer application or opening and closing of a work tool

- Programmable flow and pressure for up to 10 work tools – selection via monitor

Cat BIO HYDO Advanced HEES biodegradable hydraulic oil

SmartBoom

Generator with valve and priority function - front linkage

One-piece boom (5650 mm): – Straight stick (2500, 2900 mm)

Material Handling boom (6800 mm): – Drop Nose MH stick (4900, 5900 mm) – Straight MH stick (4800 mm)

Hydraulic quick coupler

Bucket linkages - electrical

Back-up alarm with three selectable modes

Rotating beacon on cab

Refueling pump - operator station

Falling objects guards

Joystick steering

Seat, adjustable high-back: – Mechanical suspension – Vertical air suspension

CD/MP3 radio (12V) at rear location including speakers and 12V converter

Visor for rain protection

Windshield: – One-piece fixed, high impact resistant – 70/30 split, openable

Travel speed lock - undercarriage

MH undercarriage with four welded outriggers

MH undercarriage with four welded outriggers and front mounted blade

Standard undercarriage with dozer blade (front) and outriggers (rear)

Tires, 10.00-20, solid rubber, with spacer rings - other equipment

Cat Machine Security System

Waste Handling Package (ambient capability 43° C)

MOTEUR

Power, Reliability and Fuel Economy

BENEFITS AND FEATURES

The Power and Performance You Need The Cat engine meets China Nonroad III, UN/ECE R96 Stage IIIA emission standards, and U.S. EPA Tier 3/EU Stage IIIA equivalent emission standards, delivers a maximum net power (Acc. ISO 14396) of 128.8 kW at a rated speed of 2,000 rpm.

Fuel Efficiency – Common Rail Fuel System and Fuel Pump This combination provides outstandingly low fuel consumption during both working and traveling applications.

Fuel Efficiency – Demand Fan Cooling System The electronically controlled hydraulic motor drives a variable speed on-demand fan, resulting in optimized fuel consumption.

Fuel Efficiency – One-Touch Low Idle Control The Automatic Engine Speed Control reduces engine speed if no operation is performed, reducing fuel consumption and sound levels.

Fuel Efficiency – Eco and Work Modes

- The Eco Mode can significantly reduce your fuel consumption

- The Travel Mode optimizes driveline performance while preserving fuel

- The Power Mode is the best compromise between productivity and fuel efficiency

Fast, Precise, Flexible

BENEFITS AND FEATURES

Efficient Design, Smart and Fast

- Dedicated Swing Pump – A closed hydraulic circuit is dedicated to the swing only. Having two separate pumps, one for the swing and the other for the other functions allows faster and smoother combined movements.

- Stick Circuit – Increases efficiency and helps enhance controllability for higher productivity.

- Boom, Stick and Cab Riser Hydraulic Snubbers – help cushion shocks, reduce sound and increase cylinders life.

Control Like No Other

- Heavy Lift Mode – maximizes lifting performance by boosting the lifting capability by 7%.

- Adjustable Hydraulic Sensitivity – Allows you to adjust the aggressiveness of the machine according to the application.

- Tool Control System – enables you to select up to 10 preprogrammed hydraulic work tools from the monitor. Proportional two-way flow is ideal for rotating tools with joystick sliding switches for modulated tool control.

Strength, Flexibility, Mobility

BENEFITS AND FEATURES

High Visibility – 2400 mm Elevated Cab The hydraulic cab riser is designed to be:

- Stable – Wide lift arms, deep box-sectioned design, strong top and bottom links and retractable hydraulic cylinders used to raise the cab for greater stability.

- Fast – Two heavy-duty hydraulic cylinders provide quick and controlled up and down travel.

- Comfortable – The parallelogram design of the linkage allows the cab to remain level at all ranges of motion.

- Cab movement is also slowed as it reaches the end of the riser stroke, with no sudden start/stop effect.

- Safe – The cab can be lowered using either a lever inside the cab or one on the frame at ground level in the event of a hydraulic malfunction.

Undercarriage Options Effective hydraulic line routing, transmission protection and heavy-duty axles make the Cat undercarriages perfect for material handler applications.

Three different undercarriages are available to provide the stability you need for your applications:

- Material Handling – The Material Handling undercarriage with four welded outriggers is ideal when extra stability is needed.

- Material Handling with Dozer Blade – An optional expansion to the Material Handling Undercarriage includes an additional dozer blade mounted ahead of the front stabilizers to be used to push material commonly encountered in waste and millyard applications.

- Standard – The Standard undercarriage is equipped with dozer blade at front and stabilizers at rear.

Heavy-Duty Axles The front axle offers wide oscillating and steering angles. The transmission is mounted directly on the rear axle for protection and optimum ground clearance.

Advanced Disc Brake System The disc brake system acts directly on the hub instead of the drive shaft to avoid planetary gear backlash. This minimizes the rocking effect associated with working free on wheels.

Keeps Operators Productive All Shift Long

BENEFITS AND FEATURES

Legacy from the Renowned Cat Wheel Material Handlers Designed for the operator, our cabs are unique.

Ergonomic Layout

- Frequently used switches are centralized, kept to the minimum and ideally located close to the joysticks.

- Storage compartments are useful … when well designed. The lunch box provides sufficient room to store a hard hat. Several other areas include drink, phone, or key holders.

Comfortable Seat Options Our seats provide all the comfort needed for a long day of work. The comfort seat is equipped with a passive seat climate control and air suspension which can be adjusted to the operator’s weight.

Automatic Climate Control Easy adjustment of the cab temperature with filtered ventilation.

Details That Make the Difference Have a look at the cab; you will see it is through details that we improve pleasure of operating.

Smart Controls to Reduce Fatigue

- Features like SmartBoom or joystick steering will be precious to increase your productivity.

- Two-way pedals for travel and auxiliary circuits provide increased floor space, reducing the need to change positions.

Plug, Charge and Play Your Devices

- The 12V 7A power supply socket is conveniently located for charging your laptop, or a tablet.

- A CD/MP3 radio with speakers and USB port is available.

For Ease of Operation

BENEFITS AND FEATURES

A Cab Just for You – Fully Adjustable

- Seat armrests, in height and angle

- Steering column adjustment, fore/aft tiltable

- Hydraulic sensitivity of the machine to make it more or less aggressive

- Automatic air conditioning

Low Sound Levels, Less Fatigue The rubber-mounted cab includes thick steel tubing. Associated with the comfortable air-suspended seat helps reduce vibrations and sound levels.

Visibility: See the difference!

- Halogen front roading lights and working lights

- LED rear roading lights

- All glass is affixed directly to the cab, eliminating the use of window frames.

- The 70/30 split front windshield stores the upper portion above the operator and is easy to release.

- A large skylight provides upward visibility and includes a retractable sunscreen. The parallel wiper system covers the entire front windshield.

Standard Rearview Camera Together with the best in class visibility to all sides, the rear view displayed on the monitor helps ensure a safe operation.

Large Color Monitor Easy to read and in local language, you can rely on the high resolution LCD monitor, which will keep you aware of any important information. “Quick Access” buttons allow a quick selection of favorite functions. The tool select function lets you preset up to ten different hydraulic attachments for quick tool changes.

Durability – Designed with No Compromises

BENEFITS AND FEATURES

You know that a material handler works only as good as its front linkage is able to handle the job. The M324D2 MH’s booms and sticks are purpose built for the loads encountered in material handling applications. Sticks are purposely designed with leading side plates to maximize the protection of hydraulic lines.

MH Boom MH booms include high pressure hydraulic lines for opening and closing functionality and medium pressure lines for implement rotation.

MH Sticks MH sticks are equipped with high and medium pressure auxiliary lines. The 4900 mm and 5900 mm Drop Nose Sticks offer the reaching and lifting capabilities required for typical MH applications, while the 4800 mm Straight Stick is the best solution when additional work tool functionality is needed.

Special Applications The M324D2 MH offers the ability to combine the hydraulic cab riser with a traditional excavator front linkage. This combination has been proven in transfer station, mining, and millyard applications.

When Operation Becomes as Easy as Pleasant

BENEFITS AND FEATURES

Joystick Steering Keep both hands on your joysticks even when you need to reposition the machine while simultaneously moving the implements. You can do more precise work faster.

Working Modes Get the best power output from the engine and hydraulics and maintain optimum fuel efficiency:

- Economy Mode – for precise material handling and loading with the added benefit of reduced fuel consumption.

- Power Mode – for applications requiring fast volume loading and material casting.

Automatic Travel Mode Automatically engaged when the travel pedal is depressed, this mode provides maximum speed, drawbar pull and best in class fuel efficiency.

SmartBoom™ Allow your operator to fully concentrate on production.

The unique Cat SmartBoom significantly enhances operator comfort and job efficiency by reducing stress and vibrations transmitted to the machine. Loading is more productive and more fuel efficient as the return cycle is reduced while the boom down function does not require pump flow.

Your Safety is NOT Optional

BENEFITS AND FEATURES

Smart devices are embedded to offer as much safety as possible for your operators, and help enforce safe behavior:

- Large handrails and steps assist you during cab ingress and egress.

- Anti-skid plates on all walkways and steps reduce slipping hazards, by decreasing the accumulation of mud, improving machine cleanliness and operator and technician safety.

- LED rear lights enhance visibility.

- Seat belt

- Emergency shut off switch and battery disconnect switch.

- Lowering check valves

- Standard rearview camera gives you a clear field of view behind the machine through the monitor.

- MSS Machine Security System prevents unauthorized machine use.

Move More, Make More

BENEFITS AND FEATURES

Attachment Solutions for Scrap Recycling, Bulk Handling When productivity, reliability and stability are important, Cat attachments are the perfect solution for the M324D2 MH. Choose one for your Cat machine for maximum performance.

Productive and Perfectly Matched Loading and unloading is foundational to your productivity. Grapples are sized right for the M324D2 MH. They are designed for maximum penetration into the pile. The full power of your machine is utilized to provide fast open/close times and powerful closing force. Full, 360° rotation systems allow precise placement. Together, an M324D2 MH and Cat grapple allow you to move volumes with minimal time and effort.

Built for Severe Material Cat grapples are built to take on the material you move. Hydraulic components are protected from damage, yet easily accessed for routine maintenance. Areas that dig and penetrate are made of high quality, wear resistant material to keep them in working condition. Components that pivot and move are engineered to the latest standards for a long life. Cat grapples last for a positive impact to your bottom line.

Orange Peel Grapples The perfect solution for scrap yards, recycling plants and transfer stations. These grapples are available with 4 or 5 tines, in capacities from 750 to 1000 liter. Several shell choices allow further customization of your grapple to the specific material you work with.

Clamshell Grapples The perfect solution for loading and transferring large volumes of loose material like grain, coal, sand and gravel. These grapples are configured with several shells for different capacity options to meet your specific requirements.

Power Match Match your Cat hydraulic work tools to your Cat machine, and get the most out of the standard, built-in software. Ten hydraulic pump flow and pressure settings can be preset within the monitor, eliminating the need to adjust the hydraulics each time a tool is changed. Work tool changes have never been easier!

Contact your local Cat dealer to learn more about the specific grapple choices available in your region.

It Pays to Know

BENEFITS AND FEATURES

Cat® Connect Cat Connect makes smart use of technology and services to improve your job site efficiency. Using the data from technology-equipped machines, you’ll get more information and insight into your equipment and operations than ever before.

Cat Connect technologies offer improvements in these key areas: Equipment Management – increase uptime and reduce operating costs. Productivity – monitor production and manage job site efficiency. Safety – enhance job site awareness to keep your people and equipment safe.

Featured Cat Connect technologies include the following:

Link Link technologies provide wireless capability to machines to enable two-way transfer of information collected by on-board sensors, control modules, and other Cat Connect technologies.

Manage Your Machine Remotely Cat Product Link™ is a system that is deeply integrated into the machine monitoring system to take the guesswork out of managing your equipment. The system tracks location, hours, fuel usage, productivity, idle time, and diagnostic codes and shares it with you through VisionLink® to help you maximize efficiency, improve productivity, and lower operating costs.

Generations Ahead in Every Way

BENEFITS AND FEATURES

Fuel Efficiency and Reduced Exhaust Emissions The Cat C7.1 engine meets China Nonroad III, UN/ECE R96 Stage IIIA emission standards, and U.S. EPA Tier 3/EU Stage IIIA equivalent emission standards, and performs the same amount of work as the previous model.

Fewer Leaks and Spills Lubricant fillers and drains, Cat O-ring face seals, Cat XT™ hose and hydraulic cylinders are all designed to prevent fluid leaks that can reduce the machine performance.

Biodegradable Hydraulic Oil The optional Cat Bio HYDO Advanced HEES™ is fully decomposed by soil or water microorganisms, as opposed to mineral-based oils.

Your Cat Dealer Will Support You Like No Other

BENEFITS AND FEATURES

Support You Can Count On From helping you to choose the right machine to knowledgeable on-going support, Cat dealers provide the best-in-sales and services.

- Best long-term investment with financing options and services

- Productive operation with training programs

- Preventive maintenance and guaranteed maintenance contracts

- Uptime, with best-in-class parts availability

- Repair, rebuild, or replace? Your dealer can help evaluate the best option.

Uptime Counts

BENEFITS AND FEATURES

Easy Ground Level Maintenance Our excavators are designed with the operator and technician in mind. Door opening is assisted with gas springs.

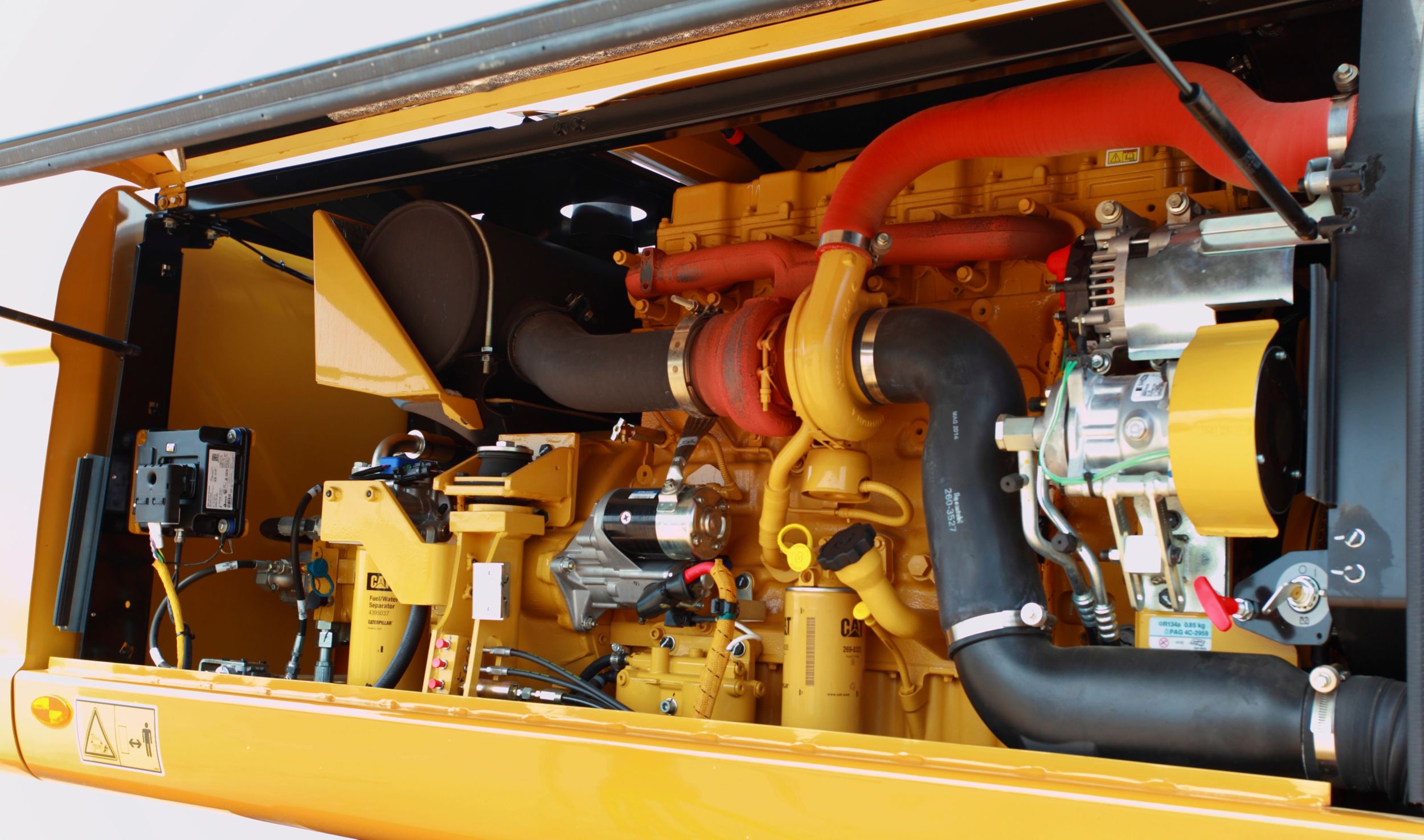

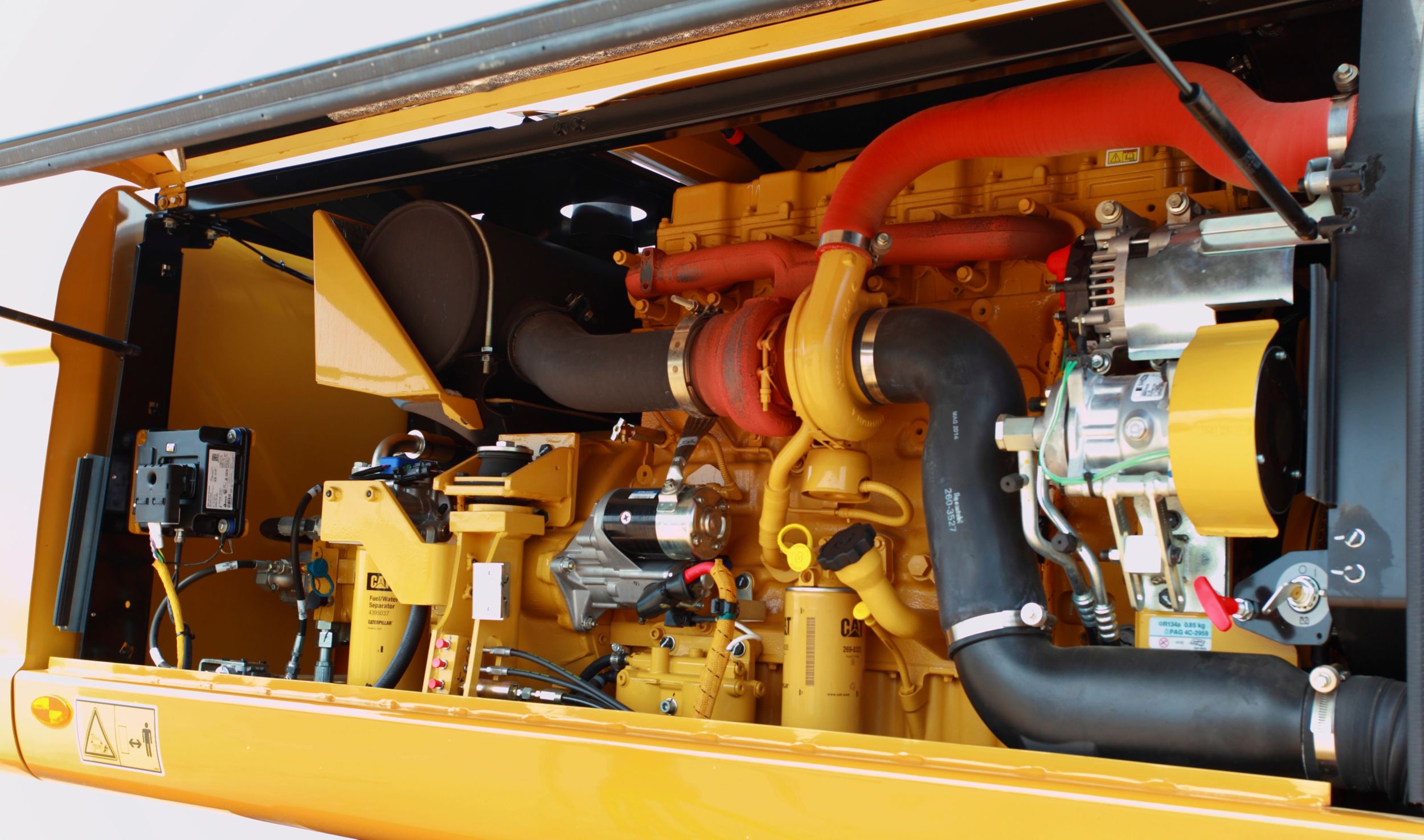

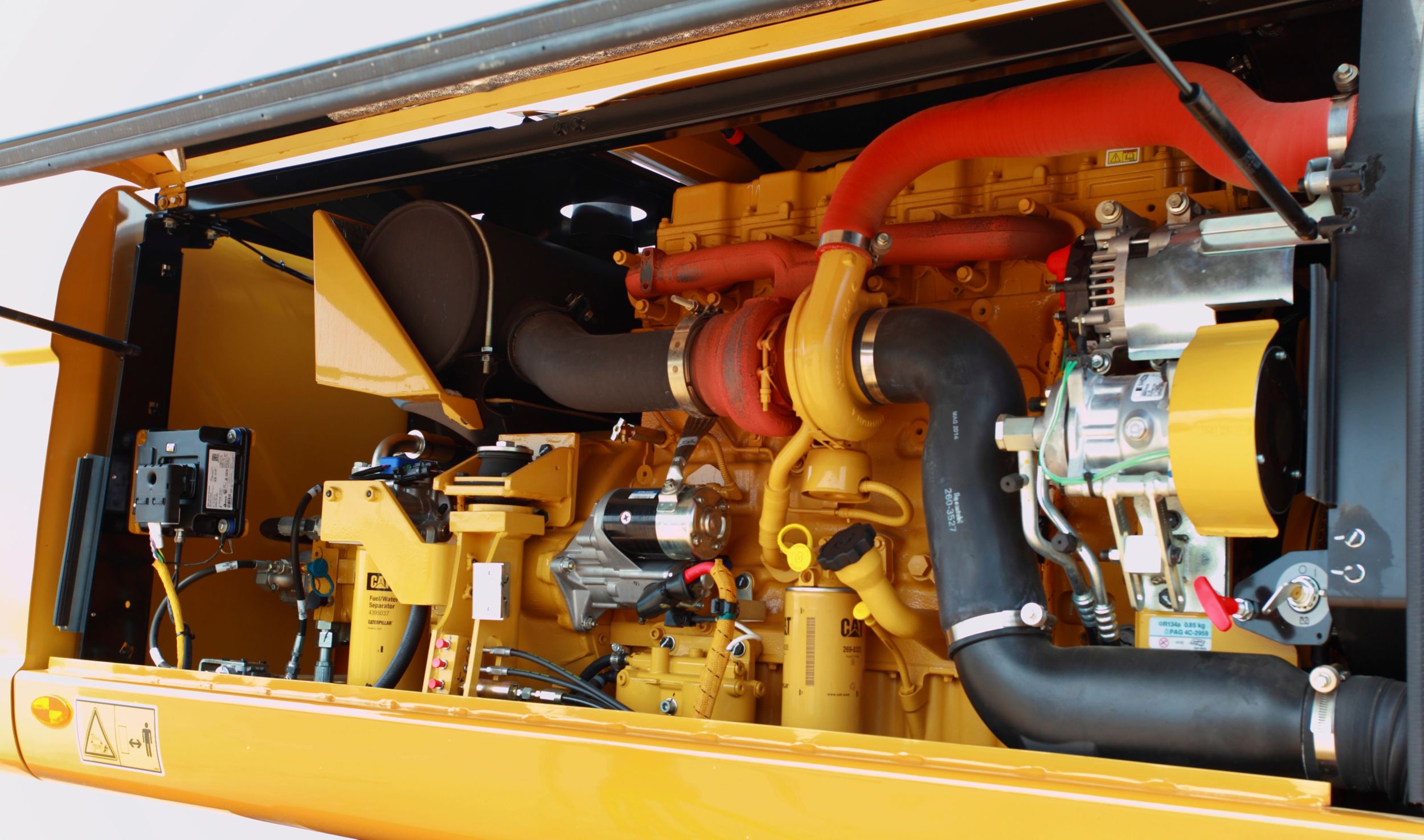

Front Compartment – Ground level access to the batteries, air-to-air aftercooler, air conditioner condenser and the air cleaner filter.

Swing-out Air Conditioner Condenser allows cleaning on both sides and access to the air-to-air aftercooler.

Engine Compartment – The longitudinal layout ensures accessibility from ground level.

Extended Service Intervals to Reduce Costs

- S·O·SSM Oil Sampling Analysis – Enhances performance and durability. This system can predict potential failures and can extend hydraulic oil change intervals up to 6,000 hours.

- Engine Oil (low ash oil) – Cat engine oil is more cost effective and provides industry-leading performance. Engine oil change interval can be extended up to 500 hours.

- Capsule Filter – The hydraulic return filter prevents contamination when the hydraulic oil is changed.

- Fuel Filters and Water Separator – The new filtration system is suited for challenging work conditions, even when using poor fuel quality. The new primary filter offers increased filtration capabilities and works in conjunction with a water separator. Fuel filters are designed to last up to 500 hours (250 hours with very poor fuel quality). The primary fuel filter includes a fuel priming pump, a water level switch and a visual restriction indicator.

- Remote Greasing – Centralized or grouped points for hard to reach and critical locations.

Waste Handling Package Specifically developed for machines working in dusty environments, this package has been tested to make sure customers can rely on it. This package includes:

- An automatic, hydraulic reversible fan that reverses airflow after a set interval, manually adjustable between 2 and 60 minutes directly from the monitor.

- A special dense wire mesh cooling system hood that further helps to reduce radiator clogging.

- A maintenance-free turbine precleaner with side dust ejection provides precleaned air to the engine air filter.

- A new air filter.

- A special dense wire mesh covering air inlets.

- A new sealing all around the front hood.