552 SERIES 2 TRACK FELLER BUNCHER

The Series 2 track feller bunchers feature smoother hydraulic performance, better fuel economy, a more comfortable operator station and better visibility. The Cat® 552 Series 2 is a full tail swing machine designed for high production clear cut and for clear or select cut in rough terrain. It is also a leveling machine for more comfort on steep terrain.

SPECIFICATIONS

Gross Power226.0 kW

Engine ModelCat® C9 ACERT™ Tier 3

Gross Power @ 1,800 rpm226.0 kW

BENEFITS AND FEATURES

hydraulic packages

Powerful hydraulic system combined with a powerful boom and stick maximize productivity

LEARN MORE

engine

Gross Power226.0 kW

Engine ModelCat® C9 ACERT™ Tier 3

Gross Power @ 1,800 rpm226.0 kW

operating specifications

Max Reach w/ Attachment8.6 m

weights

Operating Weight w/o Attachment35816.0 kg

Operating Weights (without heads)*35816.0 kg

Operating Weights (without heads)***36124.0 kg

hydraulic system

PumpsPumps

service refill capacities

Cooling System61.0 L

Engine Oil39.0 L

Hydraulic Tank323.0 L

Hydraulic System370.0 L

Swing Drive10.0 L

Fuel Capacity1181.0 L

boom system

Bare Pin Lift @ Max. Reach (without head)*9400 kg @ 6.6 m (21,800 lb @ 21.5 ft)

Bare Pin Lift @ Max. Reach (without head)***7700 kg @ 8.2 m (16,900 lb @ 27 ft)

Max. Reach (with head)*8.6 m

power train

Displacement8.8 L

Engine ModelCat® C9 ACERT™

Gross Power @ 1,800 rpm226.0 kW

Rated Power @ 2,100 rpm210.3 kW

standards

CabStandards

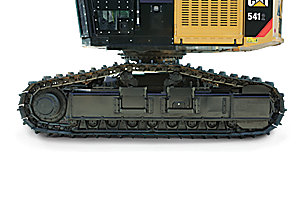

undercarriage

Ground Clearance889.0 mm

Size/Pitch345 HD/215.9 mm (345 HD/8.5 in)

Track Gauge2591 mm-2870 mm (102 in-113 in)

Track Length4903.0 mm

Tractive Effort47174.0 kg

operating weights without head

Track Feller Bunchers (long felling linkage)36124.0 kg

Track Feller Bunchers (standard linkage)35816.0 kg

BENEFITS AND FEATURES

HYDRAULIC PACKAGES

Powerful hydraulic system combined with a powerful boom and stick maximize productivity

LEARN MORE

552 Series 2 STANDARD EQUIPMENT

- electrical

24-volt electrical system

2-12 volt maintenance free batteries

95 amp alternator

IQAN programmable controls

MD3 monitor screen display

10 - standard working lights

1 - standard service light - guards

Twin hydraulically actuated hinged engine enclosure with warning alarm

Engine fan guard

Bottom guards

Isolation mounted cab and engine

Heavy duty radiator guard door - operator environment

OPS/FOPS/ROPS/WCB/OR-OSHA certified cab

Dual joystick control

Reverse slope windshield

Air ride seat

Skylight - alternate escape hatch

Top rear alternate escape hatch

3 inch retractable seat belt

Heater/air conditioner with climate control

DIN mount radio ready with speakers

Operator sound suppression to standards

Travel alarm

Cup holders (2)

2-12 volt and 1-24 volt power outlets

Front window, 31.75 mm (1.25 in) thick margard

Positive filtered ventilation, pressurized cab with bi-level air conditioner, heater and defroster with manual control

Left side fresh air window

Forced air fan

Washable floor mat

Neutral lever (lockout) for all controls - power train

C9 ACERT engine meets US EPA emission standards

Variable travel speed

Under hood centrifugal precleaner and primary air filter

Heavy-duty cooling package

Electric fuel priming pump - undercarriage

Heavy duty track motor guard

Heavy duty recoil mechanism

Track roller guards with side access holes

Hydraulic track adjusters

Double flange bottom rollers

345 HD bolted, variable gauge leveling carbody, with GFT 110 final drives - other standard equipment

Heavy duty hood enclosure

Vandalism protection

Spare hose storage area

Flexxaire™ fan

Fuel water separator

1,181 L (312 gal) fuel tank - hydraulics

Dedicated fixed displacement pilot pump

Dedicated variable displacement pumps for track and implement functions

Variable displacement saw pump for feller buncher hydraulics only

325 swing drive and swing motor

Electric hydraulic oil fill pump

High flow hydraulic arrangement for felling heads with two cylinder arm design 180 L/min (48 gpm)

Low flow hydraulic arrangement for felling heads with single cylinder and link design 120 L/min (32 gpm)

318 L (84 gal) hydraulic tank - antifreeze

50% concentration extended life coolant

552 Series 2 OPTIONS

- track systems

610 mm (24 in) SG pads, clipped corners, with mud/snow reliefs

711 mm (28 in) SG pads, clipped corners, with mud/snow reliefs

Star carrier rollers

Standard single flange carrier rollers - other equipment

Starting aid, cold weather

Starting aid, arctic - includes engine and hydraulic heaters

HID Light Group - replaces 6 standard lights - field installed attachments

CD player with AM/FM stereo - remote capable

Skylight, peaked, removable

Loose linkage arrangements

MOTEUR

Built for power, reliability, and fuel efficiency

BENEFITS AND FEATURES

Powerful Performance The Cat® C9 electronically controlled ACERT™ engine delivers power while meeting all current U.S. EPA emission standards. All models contain a fuel/water separator, engine air intake heater and a dual-stage combination air cleaner with precleaner.

High Capacity Cooling System The side-by-side radiator/oil cooler gives excellent cooling capacity for high production bunching and harvesting. On-demand Flexxaire fan activates only when required and allows the cooling fan to purge debris from the radiator area, keeping a cleaner cooling system. The IQAN control system automatically adjusts the Flexxaire fan blade angle, reducing horsepower demand and lowering fuel consumption. The purge cycle frequency and duration can be set by operator in the cab to suit varying application conditions.

Engine Oil Cat engine oil is formulated to optimize engine life and performance and is recommended for use in Cat diesel engines. Extended oil change intervals reduce maintenance and machine downtime.

Service The clamshell engine compartment provides easy access to all filters, oil dipstick, coolant reservoir, hydraulic fill pump, valves and hoses reducing maintenance time.

Low Exhaust Emissions The Cat C9 ACERT engine is a low emission engine designed to meet U.S. EPA emission regulations.

Powerful hydraulic system combined with a powerful boom and stick maximize productivity

BENEFITS AND FEATURES

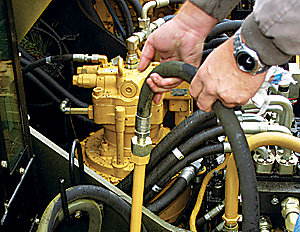

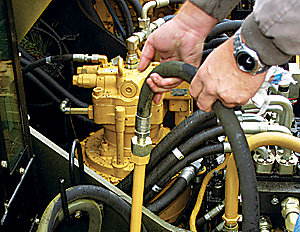

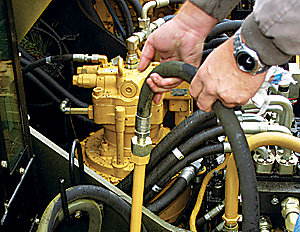

Electric Hydraulic Oil fill Pump An easy accessible service wand allows hydraulic oil to be pumped through the hydraulic filtering system and into the tank. This reduces maintenance downtime and helps to maintain oil cleanliness requirements.

Variable Displacement Pump All Cat FTS Series 2 track feller bunchers are equipped with variable displacement pumps for travel and implement functions and a dedicated variable displacement pump for felling attachments. Optional hydraulics for dangle harvesting or processor heads and intermittent saw heads are available for all models.

Valve Design Flexibility Two hydraulic implement valves are available to allow configuration of machine to operate various felling heads. Valve designs allow maximizing of machine multi-functioning performance. Valve 1) Felling heads requiring high flow 170-190 L/min (45-50 gpm) to the grab and accumulator arms. Typically have one cylinder operating each arm, two cylinders per arm set. Valve 2) Felling heads requiring low flow 110-120 L/min (29-32 gpm) to operate grab and accumulator arms. Typically one hydraulic cylinder and a link arm activate the arm set. Note: Consult the work tool manufacturer for flow requirements before selecting one of the above Hydraulic Arrangements.

Cat Hydraulic Oil Provides maximum protection against mechanical and corrosive wear in all hydraulic systems. It’s high zinc content reduces wear, and extends pump life. Biodegradable hydraulic oil (HEES) is also available from your Cat dealer and provides an environmentally-sound alternative to mineral based oils.

ToughGuard™ Hoses Abrasion resistant hoses along the boom and stick provide strength and flexibility. The ToughGuard cover consists of a thin layer of UHMW polyethylene bonded to the rubber cover, providing exceptional abrasion resistance.

Superior comfort and visibility

BENEFITS AND FEATURES

Operator Comfort The operator station is designed with conveniently placed joysticks and an ergonomically designed air ride seat, reducing operator fatigue and providing easy operation. An HVAC system with updated air ducts provides better cooling and heating. A large side window with side screen allows fresh air into the cab, and an isolated mounted cab and engine reduces sound levels and vibration for a quiet and comfortable operator environment. Ergonomically located pedals with side-by-side foot rests provide operator comfort while operating machine travel.

Visibility The cab design optimizes post structures and window placement to provide excellent operator visibility to front, sides and rear. A large polycarbonate skylight provides excellent upward visibility.

Safety The standard 32 mm (1.25 in) thick “margard” front window maximizes operator protection. All purpose built forestry cabs are designed with heavy-duty guarding, meeting FOPS/ROPS/OPS/WCB, OR-OSHA requirements. The skylight provides an alternate escape hatch.

Monitor The IQAN MD3 display allows the operator to continuously monitor the operating system of the machine. The monitor has been downsized slightly to improve the operator’s line of sight out the right front corner of the cab. The IQAN control system allows the operator to adjust control parameters, maximizing performance and productivity.

Electrical System Series 2 track feller bunchers feature a 24-volt electrical system with an in-cab 24-12 volt converter, dual in-cab 12 volt power points and one 24 volt power point. Power is provided by two 12 volt maintenance free batteries and 95 amp alternator. An optional cold weather starting attachment may be selected to provide two additional batteries, an HD starter and HD cables.

Other Features: • Large storage compartment area behind the seat provides sufficient room for a lunch box, hard hat and work tools

Stability and comfort in steep slope conditions

BENEFITS AND FEATURES

Tilt Mechanism With the most robust tilt mechanism in the industry, the 552 Series 2 tilter has a patented 3-cylinder tilt mechanism with simultaneous forward and side-by-side tilting. Trunnion cylinders are mounted on 51 mm (2 in) steel plates and transfer vertical loads down to the interface of the track frames and carbody, putting the load into the track and ground.

Cylinders A three-cylinder tilt mechanism features simultaneously 21 degree forward tilt and 11 degree side-to-side tilt.

Ground Clearance FTS machines have excellent ground clearance and open carbody design. This provides increased mobility by eliminating interference with large stumps, rocks or other obstacles encountered in rugged working conditions.

Heavy duty forestry undercarriage

BENEFITS AND FEATURES

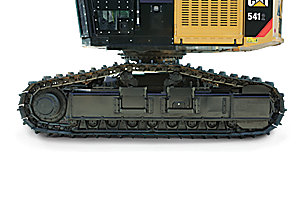

Travel Motor The proven final drives and travel motors provide up to 47 174 kg (104,000 lb) of tractive effort on the 552 Series 2, giving excellent traction and power to the ground.

Track Guards All models feature full length bolt-on track guards to maximize shoe support in all types of terrain.

Carbody The 552 Series 2 model features a bolted track frame to carbody design. This provides a standard gauge width, or allows adjustment to a wide gauge width to improve machine stability, and increase productivity on steep slope applications. The carbody design provides maximum ground clearance and a smooth under-surface to resist snagging on debris or large obstacles. The precision welded, high-wide carbody has strong frames that reduce flexing and increase the durability of rollers and track links throughout the life of the machine.

Carrier Rollers This FTS Series 2 model offers a choice of either standard single flange carrier rollers for moderate terrain and warm climates or star carrier rollers for severe terrain and cold climate applications. Nine bottom rollers per side.

Maximum reach and lift capability

BENEFITS AND FEATURES

The 552 Series 2 track feller buncher dominates in lift capacity over competitors in its size class. With market leading lift capacity, reach and tight stick tuck-in capabilities, this machine delivers high performance. Optional long and short feller buncher configurations are available and offer the same high performance.

Work tool attachments to meet your needs

BENEFITS AND FEATURES

Attachments From plantation thinning to select cut of large diameter wood, Cat felling attachments provide reliable productive felling solutions. These range in cut capacity from 572 mm (22.5 in) to 620 mm (24.4 in). Designed to allow maximum visibility of the cutting area, all saws utilize high pressure hydraulics for fast saw recovery and quick arm speed. This provides a positive impact on production and better tree control.

Tilt All models are available with a Cat 40 degree partial lateral tilt, or new 330 degree full lateral tilt.

Maximum efficiency and productivity while conserving natural resources

BENEFITS AND FEATURES

The FTS Series 2 track feller bunchers are designed to maximize efficiency and productivity while conserving natural resources.

- The C9 ACERT engine meets all current U.S. EPA emission standards

- The IQAN control system automatically adjusts the Flexxaire fan blade angle, reducing horsepower demand and lowering fuel consumption.

- Major structures and components are built to be rebuilt, reducing waste and replacement costs.

Easy servicing and extended service intervals

BENEFITS AND FEATURES

Extended Service Intervals Caterpillar service and maintenance intervals have been extended to reduce machine service time, increase machine availability and reduce operating costs. Hydraulic oil change intervals can be extended from 2,000 hours to 4,000 hours. Engine coolant change intervals are 12,000 hour with Cat Extended Life Coolant/Anti-freeze. Regularly scheduled maintenance extends machine service life and lowers overall operating costs. 500-hour oil change interval reduces overall maintenance costs.

Flexxaire Fan Standard Flexxaire fan operates only when required and allows the cooling fan to purge debris from the radiator area, reducing cleaning maintenance time. The purge cycle frequency and duration can be set by operator in the cab to suit varying application conditions.

Clam-Shell Service Doors The hydraulically actuated clam-shell service doors on both sides of machine provide easy and quick access, reducing maintenance downtime.

Count on your Cat dealer

BENEFITS AND FEATURES

Caterpillar is known the world over for the quality of customer support from its dealer network - the industry’s best. No matter where you are, the expertise of a Cat dealer is always nearby. Your local Cat dealer is your forestry consultant who can recommend the machines, work tools and services to maximize your operation and provide the support to keep you at top productivity.

- 24-hour parts availability, where and when you need them, to minimize expensive downtime

- Remanufactured parts that carry the same warranty as new parts at a reduced cost

- Operator training to get the most out of your Cat equipment

- Field services to provide on-site help when needed

- Timely repair and replacement services

- Customer Support Agreements to lower your operating costs

- State-of-the-art diagnostic programs, such as S·O·SSM oil analysis, inspection services and trend reporting to help avoid unscheduled repairs

- Financing programs for buying, renting or leasing Cat equipment

- Cat® Access Account, a fast and convenient way to pay for or rent anything offered at any Cat dealer or The Cat Rental Store

- Cat Insurance to cover equipment losses from theft, collision, flood, upset or overturn, fire, vandalism and more

- Product Link to manage your equipment fleet through remote monitoring

- Cat Certified Rebuild to get a second life from your equipment