390F L HYDRAULIC EXCAVATOR

The 390F OEM is built to keep your production numbers up and your owning and operating costs down. Not only does the machine’s C15 ACERT engine meet U.S. EPA Tier 4 Final emission standards, but it does so while giving you all the power, fuel efficiency, and reliability you need to succeed. Where the real power comes in is through advanced hydraulics and the new Adaptive Control System (ACS) valve. The ACS valve and other integrated components allow you to adapt the 390F OEM to whatever need you have. In fact, the hydraulic system and engine team together to keep fuel consumption to an absolute minimum - with zero impact on your productivity. When you add in a quiet operator environment that keeps you comfortable and productive and service points that make your routine maintenance quick and easy, you simply won’t find a better machine in this size class.

SPECIFICATIONS

Engine ModelCat® C18 ACERT™

Net Flywheel Power391.0 kW

Net Power - SAE J1349391.0 kW

BENEFITS AND FEATURES

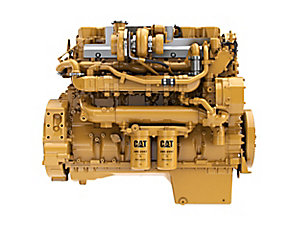

engine

Engine ModelCat® C18 ACERT™

Net Flywheel Power391.0 kW

Net Power - SAE J1349391.0 kW

Bore145.0 mm

Stroke183.0 mm

Displacement18.1 L

Engine rpm - Operation1700.0 RPM

Engine rpm - Travel1900.0 RPM

weights

Maximum Frontless Weight68660 kg

Maximum Operating Weight*86275.0 kg

*NoteDependent on application, Review

drive

Maximum Travel Speed4.5 km/h

Maximum Drawbar Pull - Long Undercarriage590.0 kN

Maximum Drawbar Pull590.0 kN

hydraulic system

Maximum Pressure - Equipment - Normal35000.0 kPa

Maximum Pressure - Travel35000.0 kPa

Maximum Pressure - Swing35000.0 kPa

Pilot System - Maximum Flow67.0 L/min

Main System - Maximum Flow (total) - Implement952.0 L/min

Main System - Maximum Flow (total) - Travel1064.0 L/min

Main System - Maximum Flow (× 2 pumps) - Implement476.0 L/min

Main System - Maximum Flow (× 2 pumps) - Travel532.0 L/min

Pilot System - Maximum Pressure4.0-4.4 MPa (580-638 psi)

Swing System - Maximum FlowNo swing pump

service refill capacities

Fuel Tank Capacity1240.0 L

Cooling System74.0 L

Engine Oil60.0 L

Swing Drive (each)19.0 L

Final Drive (each)21.0 L

Hydraulic System (including tank)997.0 L

Hydraulic Tank813.0 L

DEF Tank48.0 L

sound performance

ISO 6395 (external)109.0 dB(A)

ISO 6396 (inside cab)74.0 dB(A)

standards

BrakesSAE J1026 APR90

Cab/FOGSSAE J1356 FEB88 ISO 10262

swing mechanism

Swing Speed6.2 RPM

Swing Torque260.0 kN·m

track

Optional for Long Undercarriage650.0 mm

Number of Carrier Rollers Each Side3

Number of Shoes Each Side - Long Undercarriage51

Number of Track Rollers Each Side - Long Undercarriage9

Optional for Long Undercarriage750.0 mm

Standard with Long Undercarriage900.0 mm

BENEFITS AND FEATURES

390F L OEM STANDARD EQUIPMENT

- machine

C18 ACERT diesel engine meets U.S. EPA Tier 4 Final emission standards

2300 m (7,500 ft) altitude capability with no derate

80 amp alternator

Eco mode

Lift mode

Main control valve with ACS

Hydraulic main pump (2 pump)

Three SBS radiators for easy cleaning

Automatic engine speed control

Water separator in fuel line including water level sensor and indicator

Four micron fuel filter

Electrical priming pump with switch

Electrical connector for a beacon - requires additional hardware

Bio fuel capability

Two speed travel

Circuit breaker

Right-side light

Cab skirt light

Platform light

Door locks and cap locks

Signaling/warning horn

Mirrors, rearview (frame - right, cab - left)

Steel wall between engine and pump compartment

Cat data link with capability of using E.T.

Boom drift reducing valve*

Stick drift reducing valve*

Reverse swing damping valve*

Automatic swing parking brake

Counterweight with lifting eyes

Secondary engine shutoff switch

Product Link standard

High-performance hydraulic return filter

Provision for Cat Grade Control, depth and slope - base machine (2D)

Reversing cooling fan

Cat walk

Air cleaner

Battery - cab

Rearview camera

Bolt-on FOGS capability

Sliding upper door window

Safety hammer for breaking glass

Removable lower windshield with in-cab storage bracket

Openable skylight

Interior lighting

Coat hook

Beverage holder

Literature holder

Utility space for magazine

Radio mounting

Two stereo speakers

Storage compartment suitable for lunch box

Language display - full graphic, video ready

Warning information, filter/fluid change information, working hour information

Machine condition, error code and tool mode setting information

Start up level check for hydraulic oil, engine oil and engine coolant

Full time clock on monitor

Height-adjustable armrest

Height-adjustable consoles

Neutral lever (lock out) for all controls

Travel control pedals with removable hand levers

Power supply 12V with 2 socket, 1 × 10A converter

Pressurized operator station

Gain/response map selection (production, normal, control)

Cat one key security system - undercarriage

Track rollers, single flange type

Towing eye on base frame

Heavy-duty track roller

Track motor guards

390F L OEM OPTIONS

- track

Double grouser 650 mm (26 in)

Double grouser 750 mm (30 in)

Double grouser 900 mm (35 in) - guards

FOGS (Falling Object Guard System) including overhead and windshield guards

Track guiding guards: - Full length - Center section - Three piece

Vandal guards for windshield - auxiliary controls and lines

Basic control arrangements - miscellaneous options

Adjustable high-back heated seat with mechanical suspension

Adjustable high-back seat with air suspension and heater

Boom lowering control device

Counterweight removal system

Cold weather package with additional battery, ether aid, jump start and engine block heater

Straight travel pedal

Cab front rain protector

HID cab lights with time delay

Radio

AM/FM radio mounted in right-hand console with antenna and two speakers

Radio ready mounting at rear location including 24 volt to 12 volt converter

Fast fill fuel system

Quick fill and drains for engine oil and hydraulic oil

Cat Grade Control

MOTEUR

Power to move your material with speed and precision

BENEFITS AND FEATURES

A Powerful, Efficient Design When it comes to moving heavy material quickly and efficiently, you need hydraulic horsepower - the type of ground-breaking power the 390F can deliver. Major components like the pumps, main control valve, and oil tank are positioned to reduce the effects of heat and hydraulic sound level on operators. And they are close together so shorter tubes and lines can be used. All of this leads to less friction loss, reduced pressure drops, and more power to the ground for the tons of work you need to get done.

Control Like No Other Controllability is one of the main attributes of Cat excavators, and one of the key contributors to this is the new ACS valve. The valve is designed to intelligently manage restrictions and flows. It opens slowly when your range of joystick lever movement is small and opens rapidly when movement is high. It puts flow exactly where you need it when you need it, which means you will experience much smoother operation, greater efficiency, and lower fuel consumption. The ACS valve also has a new automatic hydraulic oil warm-up function - a definite plus in putting your machine to work more quickly in cold weather conditions.

Powerful and fuel efficient to meet your expectations

BENEFITS AND FEATURES

Proven Technology Every U.S. EPA Tier 4 Final ACERT engine is equipped with a combination of proven electronic, fuel, air, and aftertreatment components. Applying these time-tested technologies lets us meet your high expectations for productivity, fuel efficiency, reliability, and service life. Following are the results you can expect:

- High performance across a variety of applications.

- Enhanced reliability through commonality and simplicity of design.

- Maximized uptime and reduced cost with world-class Cat dealer support.

- Minimized impact of emission systems - with no operator interaction required.

- Durability with long service life.

- Improved fuel efficiency with minimized maintenance costs.

- Same great power and response.

An Emissions Solution That Works The Cat C18 ACERT engine meets today’s U.S. EPA Tier 4 Final emission standards, and it does so without interrupting your job process. Simply turn the engine on and go to work. It will look for opportunities in your work cycle to regenerate itself, and it will give you plenty of power for the task at hand - all to help keep your owning and operating costs to an absolute minimum.

Fuel Savers That Add Up The 390F consumes significantly less fuel than the previous series model, and two built-in features help contribute to that: automatic engine speed control and automatic engine idle shutdown. Automatic engine speed control lowers rpm when the machine doesn’t need it for work. Automatic engine idle shutdown turns the engine off when it’s been idling for more than a specified amount of time, which will lower fuel consumption, hour accumulation, and lead to extended service intervals and higher resale value. A choice of two power modes - high power and economy mode - lets you manage fuel consumption for the work at hand. Collectively, all of these benefits add up to reduced fuel consumption, reduced exhaust and sound emissions, reduced repair and maintenance costs, and increased engine life for you.

A Cool Design For Any Temperature The 390F features a new side-by-side cooling system that allows you to put the machine to work in extremely hot and cold conditions. The system is completely separated from the engine compartment to reduce noise and heat. Plus it features easy-to-clean cores and a new variable-speed fan that reverses to blow out unwanted debris that may accumulate during your work day.

Biodiesel Not A Problem The Cat C18 ACERT engine can run on B20 biodiesel fuel that meets ASTM 6751 standards - all to give you more potential fuel-saving flexibility.

Comfort and convenience to keep you productive all day long

BENEFITS AND FEATURES

A Safe, Quiet Cab The all-new cab provides you with a safe working environment. It also contributes to your comfort because it’s attached to a reinforced frame with special viscous mounts that limit vibration and unnecessary sound. Add in special roof lining and sealing and you have a cab that’s as quiet as any of today’s top pickup trucks.

Comfortable Seat Options Air suspension, heated, and cooled seat options are available. All seats include a reclining back, upper and lower slide adjustments, and height and tilt angle adjustments to meet your needs for maximum comfort.

A Cool Warm Environment

Controls Just For You

BENEFITS AND FEATURES

18588144 A Helpful Monitor

18588144 Ample Storage

Cat Connect makes smart use of technology and services to improve your job site efficiency. Using the data from technology-equipped machines, you’ll get more information and insight into your equipment and operations than ever before. Cat Connect technologies offer improvements in these key areas: Equipment Management - increase uptime and reduce operating costs. Productivity - monitor production and manage job site efficiency. Safety - enhance job site awareness to keep your people and equipment safe.

18588151

BENEFITS AND FEATURES

http://s7d2.scene7.com/is/image/Caterpillar/C10124230?$Type2$

BENEFITS AND FEATURES

BENEFITS AND FEATURES

BENEFITS AND FEATURES

BENEFITS AND FEATURES

http://s7d2.scene7.com/is/image/Caterpillar/C10081739?$Type2$

BENEFITS AND FEATURES

BENEFITS AND FEATURES

BENEFITS AND FEATURES

http://s7d2.scene7.com/is/image/Caterpillar/C10124177?$Type2$

BENEFITS AND FEATURES

BENEFITS AND FEATURES

BENEFITS AND FEATURES

BENEFITS AND FEATURES

On-board electric lubricator and auto lube systems are available time-saving attachments. The on-board lubricator has a grease container, greasing pump, and a hose with nozzle to help you reach all the greasing points. The auto lube system will do the work for you. An electric refueling pump attachment is also available, and it allows you to refuel from other sources like a barrel or fuel reservoir when a fuel truck or regular fuel pump isn’t on site. The pump automatically shuts off when the fuel tank is full.

BENEFITS AND FEATURES

The fuel tank’s drain cock makes it easy and simple for you to remove water and sediment during routine maintenance. Plus an integrated fuel level indicator pops up to help you reduce the possibility of fuel tank overfilling.

BENEFITS AND FEATURES

Features to help protect you day in and day out

BENEFITS AND FEATURES

A Safe, Quiet Cab The all-new cab provides you with a safe working environment. It also contributes to your comfort because it’s attached to a reinforced frame with special viscous mounts that limit vibration and unnecessary sound. Add in special roof lining and sealing and you have a cab that’s as quiet inside as any of today’s top pickup trucks.

Secure Contact Points Multiple large steps will get you into the cab as well as a leg up to the catwalks and compartments. Extended hand and guard rails allow you to safely climb to the upper deck. Anti-skid plates on the catwalks, the surface of the upper structure, and the top of the storage box area reduce your slipping hazards in all types of weather conditions. And they can be removed for cleaning.

Great Views Ample glass gives you excellent visibility out front and to the side, and the standard rearview camera gives you a clear field of view behind the machine through the cab monitor. The available split-configuration windshield features an upper window with handles that make it easy to slide and store above you and a lower window that can be removed and stored on the inside wall of the cab. An available one-piece windshield comes with a safety hammer to break it in case of an emergency. The large skylight also serves as an emergency exit and provides you with enhanced overhead visibility.

Smart Lighting Halogen lights provide plenty of illumination. Cab and boom lights can be programmed to stay on for up to 90 seconds after the engine has been turned off to help you safely exit the machine. Optional High Intensity Discharge (HID) lights are available for enhanced night-time visibility.

Support you can count on

BENEFITS AND FEATURES

Worldwide Parts Availability Cat dealers utilize a worldwide parts network to maximize your machines’ uptime. Plus they can help you save money with Cat remanufactured components.

Advice You Can Trust What are the job requirements and machine attachments? What production is needed? Your Cat dealer can provide recommendations to help you make the right machine choices.

Financial Options Just For You Consider financing options and day-to-day operating costs. Look at dealer services that can be included in the machine’s cost to yield lower owning and operating costs over time.

Support Agreements To Fit Your Needs Cat dealers offer a variety of customer support agreements and work with you to develop a plan to meet your specific needs. These plans can cover the entire machine, including attachments, to help protect your investment.

Operating Techniques To Boost Your Profits Improving operating techniques can boost your profits. Your Cat dealer has videos, literature, and other ideas to help you increase productivity. Caterpillar also offers simulators and certified operator training to help maximize the return on your investment.

What’s Best For You Today…And Tomorrow Repair, rebuild, or replace? Your Cat dealer can help you evaluate the cost involved so you can make the best choice for your business.

Generations ahead in every way

BENEFITS AND FEATURES

- The C18 ACERT engine meets U.S. EPA Tier 4 Final emission standards.

- The 390F performs the same amount of work while burning significantly less fuel than the previous D Series model, which means more efficiency, less resources, and fewer CO2 emissions.

- The 390F has the flexibility of running on either ultra-low-sulfur diesel (ULSD) fuel with 15 ppm of sulfur or less or biodiesel (B20) fuel blended with ULSD.

- An overfill indicator rises when the tank is full to help the operator avoid spilling.

- Quick fill ports with connectors ensure fast, easy, and secure changing of hydraulic oil.

- The machine is built to be rebuilt with major structures and components remanufactured to reduce waste and replacement costs.

- The 390F is an efficient, productive machine that’s designed to conserve our natural resources for generations ahead.