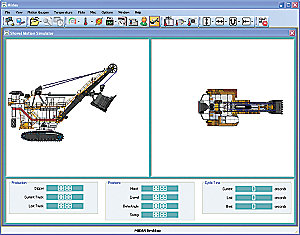

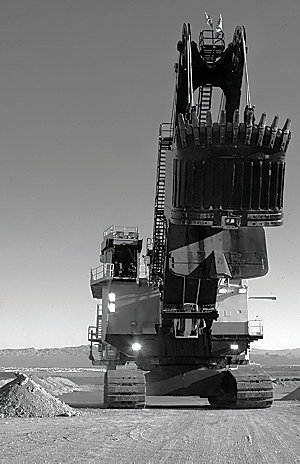

7295 ELECTRIC ROPE SHOVEL

Cat® Electric Rope Shovels are built specifically for removing large amounts of overburden and ore, at a fraction of the cost per ton.

SPECIFICATIONS

Dipper payload45.4 tonnes

Dipper capacity18.4-39.0 m3 (24-51 yd3)

Effective length of dipper handle9.45 m

BENEFITS AND FEATURES

support

Caterpillar factory-trained service engineers are available throughout the world to ...

LEARN MORE

ac igbt electrics

With over 30 years of AC experience and over 200 operating AC machines, Bucyrus led the ...

LEARN MORE

accessdirect™

AccessDirect is an electrical interface system that facilitates remote access to a ...

LEARN MOREdimensions

Dipper payload45.4 tonnes

Dipper capacity18.4-39.0 m3 (24-51 yd3)

Effective length of dipper handle9.45 m

Length of boom18.0 m

Overall length of dipper handle12.65 m

weights

Working weight, with dipper and standard links789251.0 kg

Ballast (furnished by customer)159665.0 kg

General purpose dipper - 25.2 m3 (33 yd3)49895.0 kg

Net weight, domestic, without ballast or dipper579691.0 kg

NoteThese weights will vary slightly depending upon dipper and optional equipment selection.

front end

Boom - Boomwelded, impact-resistant steel

Boom - Boom point sheave diameters2.08 m

Boom - Boom point sheavestwin-grooved, flame-hardened

Boom - Handle diameter86.36 cm

Boom - Wall thickness (nominal)4.45 cm

Rope Data - Boom susp. - Constructionstruct. strand

Rope Data - Boom susp. - Diameter69.9 mm

Rope Data - Boom susp. - No.4

Rope Data - Boom susp. - Typeequalized

Rope Data - Crowd - Construction8 x 37

Rope Data - Crowd - Diameter60.3 mm

Rope Data - Crowd - No.1

Rope Data - Crowd - Typesingle dual

Rope Data - Dipper trip - Construction7 x 25

Rope Data - Dipper trip - Diameter16.0 mm

Rope Data - Dipper trip - No.1

Rope Data - Dipper trip - Typesingle

Rope Data - Hoist - Construction6 x 41

Rope Data - Hoist - Diameter57.2 mm

Rope Data - Hoist - No.2

Rope Data - Hoist - Typetwin dual

Rope Data - Retract - Construction8 x 37

Rope Data - Retract - Diameter60.3 mm

Rope Data - Retract - No.1

Rope Data - Retract - Typesingle dual

electrical

Distribution System Requirements - Machine on large system1320 kVA

Distribution System Requirements - Machine on separate system2000 kVA

DriveIGBT Acutrol drive system.

Main Electrical Systems - Lighting transformer1 x 25 kVA, 120/240V secondary

Main Electrical Systems - System voltage (nominal)50/60 Hz, 7,200V

Main Electrical Systems - Trail cable (furnished by customer)SHD-3-#4 at 8,000V

Main Electrical Systems - Transformer, auxiliary250 kVA, 7,200V primary; 480V secondary

Power Requirements - Average 15-minute demand538-753 kW

Power Requirements - Peak power2152 kW

Power Requirements - Voltage3 phase, 50/60 Hz, 7,200V (Other voltages available to suit customer requirements.)

main structures

Crawler Mounting - Number and diameter of rollers: Lower (16)71.0 cm

Crawler Mounting - Number and diameter of rollers: Lower rear (2)89.0 cm

Crawler Mounting - Number and diameter of rollers: UpperSlides

Crawler Mounting - Number and pitch of treads (96)45.0 cm

Crawler Mounting - Overall length of mounting10.26 m

Crawler Mounting - Overall width 139.7 cm (55 in) treads, standard8.2 m

Crawler Mounting - Overall width 182.88 cm (72 in) treads8.63 m

Crawler Mounting - Take-up tumblers diameter120.7 cm

Crawler Mounting - Total effective bearing area (139.7 cm/55 in treads)20.81 m2 (224 ft2); 371.6 kPa (53.9 psi)

Crawler Mounting - Total effective bearing area (182.88 cm/72 in treads)27.2 m2 (293 ft2); 284.1 kPa (41.2 psi)

HoistHoist machinery consists of a motor coupled to two gear reductions, which drive the 137 cm (54 in) hoist drum.

Planetary PropelDual-motor independent drive.

Revolving Frame - Welded, impact-resistant steel: Length6.92 m

Revolving Frame - Welded, impact-resistant steel: Width3.2 m

SwingTwo parallel shaft units mounted to either side of the revolving frame. Each unit is driven by a vertically mounted motor.

Turntable - Cast alloy steel swing rack pitch diameter4.37 m

Turntable - Number of tapered rollers54

Turntable - Tapered rollers diameter18.73 cm

Turntable - Tapered, forged alloy steel roller rails diameter3.92 m

Turntable - Teeth external cut (face)20.32 cm

optimal working ranges

Clearance height (boom point sheaves)18.15 m

Clearance radius (boom point sheaves)17.48 m

Clearance radius (revolving frame)7.98 m

Clearance under frame (to ground)3.07 m

Clearance under lowest point in truck frame/propel gearcase0.78 m

Cutting height (maximum)15.56 m

Cutting radius (maximum)21.78 m

Dumping height9.22 m

Dumping height at maximum electric crowd limit7.0 m

Dumping radius (maximum)18.69 m

Height of A-frame11.94 m

Operator’s eye level8.2 m

Overall width12.39 m

Radius of level floor15.58 m

lights

TypesIncandescent lights on ground lights, walkways and operator’s cab.

TypesHPS lights on boom feet, top of A-frame, machinery house, lube room, control room, utility room and flood lights.

crowd

ComponentsRope Crowd with crowd machinery located at front center of the revolving frame; consisting of a motor, brake, drum and gearing.

ComponentsPlastic-coated crowd and retract ropes are used to move the dipper handle fore and aft.

lube system

Components4 pumps (2 for lubricant and 2 for grease) located in an insulated, double-walled lube room.

TypeSingle-line system applies lubricant and grease via the PLC.

BENEFITS AND FEATURES

SUPPORT

Caterpillar factory-trained service engineers are available throughout the world to ...

LEARN MORE

AC IGBT ELECTRICS

With over 30 years of AC experience and over 200 operating AC machines, Bucyrus led the ...

LEARN MORE

ACCESSDIRECT™

AccessDirect is an electrical interface system that facilitates remote access to a ...

LEARN MORE

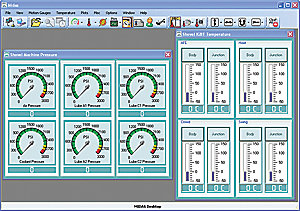

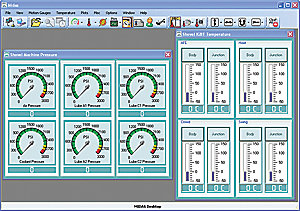

MIDAS™

Celebrating its tenth anniversary on the market, the MIDAS health monitoring system ...

LEARN MORE

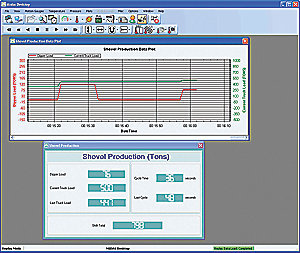

ACCULOAD™

AccuLoad is a data analysis system that provides real-time feedback on dipper loads with ...

LEARN MORE

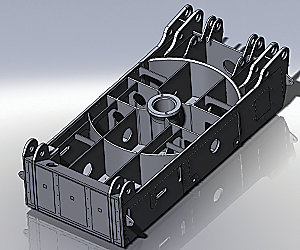

MAJOR STRUCTURES

Cat major structures are designed for extended performance in harsh mining conditions. ...

LEARN MORE

ROBUST FRONT END DESIGN

The Cat free-floating tubular handle design presents many benefits over traditional ...

LEARN MORE

CAT® CAB

Caterpillar’s new state-of-the-art operator’s cab is the product of a multi-year ...

LEARN MORE

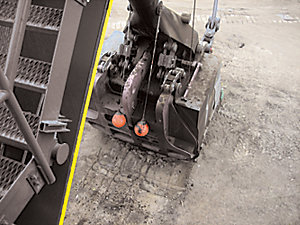

LATCHFREE™ DIPPER SYSTEM

The LatchFree Dipper System is Caterpillar’s solution to customers’ number-one cause ...

LEARN MORE

FASTFIL™ DIPPER DESIGN

The unique FastFil dipper provides customers with faster and fuller dipper loads. Its ...

LEARN MORE

SAFETY

Safety plays an integral role in everything we do at Caterpillar, from our factory floors ...

LEARN MOREMOTEUR

Support

BENEFITS AND FEATURES

BENEFITS AND FEATURES

AC IGBT Electrics

BENEFITS AND FEATURES

18295673 AccessDirect™

18295674 MIDAS™

18295675 AccuLoad™

18295676 Major Structures

18295656 Robust Front End Design

18295657 Cat® Cab

18295658 HydraCrowd™

18295658

18295659 LatchFree™ Dipper System

18295660 FastFil™ Dipper Design

18295661 Safety

18295662 Training

18295662

18295677 Computer Based Training (CBT) Modules

18295677