D8R TRACK-TYPE TRACTOR

Caterpillar has been designing and building dozers for more than a century. The latest D8R builds on a long-standing reputation for reliable performance, and adds a new cab with features to help operators be more productive. The Cat D8R is designed to be durable, especially in challenging conditions like extreme heat and cold, sandy deserts and rocky terrain. It offers renowned versatility and productivity, along with ease of repair and service to keep the machine hard at work on your job site.

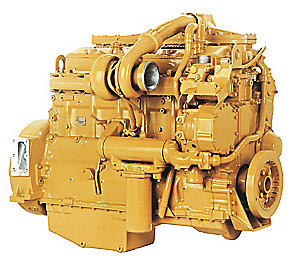

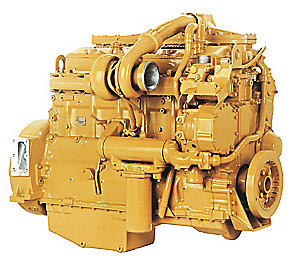

engine

Engine ModelCat® 3406C DITA

Flywheel Power226 kW

Bore137 mm

Stroke165 mm

Displacement14.6 L

Engine Power (Maximum) – ISO 14396247 kW

Engine Power (Maximum) – ISO 14396 (DIN)247 kW

Engine Power (Maximum) – SAE J1995252 kW

Net Power (Maximum) – 80/1269/EEC239 kW

Net Power (Maximum) – ISO 9249/SAE J1349239 kW

Net Power (Maximum) – ISO 9249/SAE J1349 (DIN)239 kW

Net Power (Rated at 2,100 rpm) – 80/1269/EEC226 kW

Net Power (Rated at 2,100 rpm) – ISO 9249/SAE J1349226 kW

Net Power (Rated at 2,100 rpm) – ISO 9249/SAE J1349 (DIN)226 kW

weights

Operating Weight37557 kg

Operating Weight – Standard (SU)37557 kg

Operating Weight – Standard (U)38192 kg

Operating Weight – LGP (SU)35562 kg

Operating Weight – A38374 kg

transmission

1.0 Forward3.5 km/h

1.0 Reverse4.7 km/h

2.0 Forward6.2 km/h

2.0 Reverse8.1 km/h

3.0 Forward10.8 km/h

3.0 Reverse13.9 km/h

service refill capacities

Fuel Tank625 L

Cooling System92 L

Power Train144 L

Final Drives (each)13.5 L

Engine Crankcase32.5 L

Hydraulic Tank72 L

Pivot Shaft40 L

hydraulic controls

Lift Cylinder Flow325 L/min

Tilt Cylinder Flow170 L/min

Pump Capacity at7000 kPa

Pump Output239 L/min

Pump Type – ImplementsVariable Displacement Piston

RPM at Rated Engine Speed2100 rpm

Ripper Cylinder Flow190 L/min

standards

ROPSIntegrated ROPS (Rollover Protective Structure) offered by Caterpillar for the machine meets ROPS criteria ISO 3471:2008

CabMeets the appropriate standards

BrakesBrakes meet the standard ISO 10265:2008

ripper

Type: Adjustable Parallelogram Single-Shank – Number of Pockets1

Type: Adjustable Parallelogram Single-Shank – Weight with Standard Single Shank4085 kg

Type: Adjustable Parallelogram Single-Shank – Maximum Penetration1135 mm

Type: Adjustable Parallelogram Single-Shank – Maximum Penetration Force127.4 kN

Type: Adjustable Parallelogram Single-Shank – Pryout Force222.8 kN

Type: Adjustable Parallelogram Multi-Shank – Number of Pockets3

Type: Adjustable Parallelogram Multi-Shank – Weight with Three Shanks4877 kg

Type: Adjustable Parallelogram Multi-Shank – Overall Beam Width2464 mm

Type: Adjustable Parallelogram Multi-Shank – Maximum Penetration780 mm

Type: Adjustable Parallelogram Multi-Shank – Maximum Penetration Force124.2 kN

Type: Adjustable Parallelogram Multi-Shank – Pryout Force227.9 kN

hydraulic controls – maximum operating pressure

Bulldozer, Lift24100 kPa

Bulldozer, Tilt24100 kPa

Ripper, Lift24100 kPa

Ripper, Tilt24100 kPa

Steering38000 kPa

hydraulic controls – main relief valve

Pressure Setting24100 kPa

blades

A – Blade Capacity4.70 m3

A – Blade Width4978 mm

SU LGP – Blade Capacity8.50 m3

SU LGP – Blade Width4400 mm

SU – Blade Capacity8.70 m3

SU – Blade Width3937 mm

U – Blade Capacity11.70 m3

U – Blade Width4262 mm

undercarriage – lgp

Ground Clearance613 mm

Ground Contact Area6.19 m2

Ground Pressure (ISO 16754)50.7 kPa

Grouser Height78 mm

Length of Track on Ground3206 mm

Pitch216 mm

Shoe TypeModerate Service

Shoes/Side44

Track Gauge2337 mm

Track Rollers per Side8

Width of Shoe965 mm

undercarriage – standard

Ground Clearance613 mm

Ground Contact Area3.91 m2

Ground Pressure (ISO 16754)95.1 kPa

Grouser Height78 mm

Length of Track on Ground3206 mm

Pitch216 mm

Shoe TypeModerate Service

Shoes/Side44

Track Gauge2083 mm

Track Rollers per Side8

Width of Shoe610 mm

engine

NoteCat 3406C DITA engine is capable of meeting the equivalent of non-current U.S. EPA Tier 1 or EU Stage I emission standards.

weights

Shipping Weight – Standard28213 kg

Shipping Weight – LGP29302 kg

undercarriage – standard

Ground Pressure (ISO 16754): Standard – SU84.7 kPa

Ground Pressure (ISO 16754): Standard – U86.2 kPa

Ground Pressure (ISO 16754): Standard – A86.6 kPa

standards

FOPSFOPS (Falling Object Protective Structure) meets ISO 3449:2005 Level II

BENEFITS AND FEATURES

D8R STANDARD EQUIPMENT

- electrical

75 amp alternator

Back-up alarm

Forward warning horn - operator environment

EMS (Electronic Monitoring System) with temperature gauges

Fuel level gauge

Retractable seat belt (76 mm/3 in)

Rearview mirror - power train

Decelerator

Engine doors

Fuel priming pump

Muffler

Prescreener

Torque divider

Powershift transmission (3-speed) - undercarriage

8-roller tubular track roller frame

Hydraulic track adjusters

Track guides - other standard equipment

Differential steering with dual-twist tiller control

Independent steering and implement

Hydraulic oil cooler

Hydraulic valve – for blade and ripper

Mounting, lift cylinder

Blade lift cylinder – left hand

Blade lift cylinder – right hand

D8R OPTIONS

- tractor arrangements

Standard

LGP

Desert Arrangement

Waste Handler Arrangement - technology products

Product Link – PL321

Product Link – PL522 - power train

Engine with thermal shield

High speed oil change - starting aids

Ether aid

Heater, diesel fuel

Heather, engine 240V

System, prelube - air precleaner

Precleaner: – Standard – Turbine – Turbine with screen - engine cooler

Radiator: – AMOCS – AMOCS, high ambient and abrasion resistant – AMOCS, debris resistant – Debris and abrasion resistant - fan speed ratio

Fan drive: – Standard – Speed increase (high ambient) – Speed decrease - operator station

Integrated ROPS open canopy

Integrated ROPS enclosed cab

Vinyl or cloth covered suspension seats

Rear screen guards - guards

Fuel tank

Heavy-duty radiator

Sweeps - electrical

Lighting options of 4, 6, 8 or 10 - rear attachments

Drawbar

Counterweight

Rippers: – Multi-shank – Single shank - bulldozer

Semi-Universal blade

Universal blade

Angle blade - cooling fan

Fan, blower: – Standard – Coated – Ejector – Reversible - fuel refill system

Cover, fuel tank

Adapter, fast fuel - final drive

Standard

Standard, guarded

LGP

LGP, guarded

Standard, arctic - undercarriage

Basic, suspended

Positive pin retention: – Guarded – Arctic – Non-suspended

Non-suspended, guarded - carrier roller

No carrier roller, suspended

Carrier roller, suspended

Carrier rollers: – Suspended, arctic – Non-suspended – Non-suspended, arctic - positive pin retention track

Track pairs: – Extreme service (44 sections) (560 mm/22 in; 560 mm/22 in, trapezoidal; 560 mm/22, steel mill; 610 mm/24 in; 610 mm/24 in, trapezoidal; 610 mm/24 in, chopping; 660 mm/16 in; 660 mm/26 in, trapezoidal; 710 mm/28 in; 710 mm/28 in, trapezoidal; 965 mm/38 in, trapezoidal; 965 mm/38 in) – Moderate service (44 sections) (610 mm/24 in; 660 mm/26 in; 710 mm/28 in; 710 mm/28 in; 965 mm/38 in) – Super extreme service (610 mm/24 in; 660 mm/26 in, trapezoidal) - hydraulics

Bulldozer tilt hydraulics: – Hydraulic, single tilt – Hydraulic, dual tilt

Lubricant: – Standard – High ambient – Arctic - electrical

Batteries: – Standard – Heavy duty

Lights: – Four – Six – Ten – Eight (sweeps) – Eight (sweeps and rear screen) – Ten (ROPS A/C) - operator environment

Operator station: – Canopy – Cab (Standard; Arctic)

Air conditioner: – No air conditioner – Air conditioner (Under hood; ROPS mounted)

Seat: – Vinyl – Cloth – Cloth, air suspension - guards

Guards: – Bottom, heavy duty – Bottom, heavy duty, sealed

Grid, radiator core protector

Screen group: – Rear – Rear (canopy)

Guard: – Fuel tank – Rear transmission

Striker bars: – Front (suspended) – Front (non-suspended) - rear attachments

Drawbar, rear, rigid

Ripper: – Single shank – Single shank, pin puller – Single shank, push block – Multi-shank

Counterweight, rear

Ripper single shank with striker bar

Ripper single shank pin and striker bar

Ripper multi shank with striker bars

Ripper single shank with push block and pin puller

Striker bar, rear

No rear attachment - other attachments

Counterweight: – Drawbar – Additional

Fast oil change system

Paint, black hood and cylinders - push arms

Bulldozer: – Push arm, single – Push arm, dual tilt - blades

8SU: – 8SU, with rock guard and wear plate – 8SU push plate – 8SU landfill wear plate – 8SU LGP – 8SU LGP landfill

8U: – 8U rock guard/wear plate – 8U landfill wear plate

8A - ground engaging tools

Tooth: – Multi-shank – Single shank – Single shank, deep ripping

MOTEUR

Comfort and productivity

BENEFITS AND FEATURES

An updated cab, with an Integrated Roll Over Protection Structure (ROPS), gives operators greater all around visibility to enhance safety and productivity. It offers a quieter interior, with improved pressurization to help keep dust out for a cleaner operating environment. The redesigned instrument panel is easy to read, showing fuel level and engine RPM, as well as temperature levels for power train oil, hydraulic oil and engine coolant. The Cat Electronic Monitoring System keeps the operator informed about machine operating conditions. Three-level alert indicators monitor coolant flow, coolant temperature, engine oil pressure, transmission oil temperature, alternator low voltage and transmission/hydraulic oil filter restriction.

Implement and Steering Controls All D8R controls are ergonomically designed for low-effort and ease of operation.

- The operator uses a single handle control to perform all direction and gear selection for ease of operation. The tiller bar control allows the operator to work more precisely in close areas around structures, grade stakes and other machines.

- New pilot hydraulic implement controls reduce operator effort and offer more consistent, precise and responsive operation.

Built to get the job done

BENEFITS AND FEATURES

Engine A powerful Cat 3406 diesel engine allows the D8R to doze through tough material. This field proven mechanical engine also features a modular design for ease of service.

Differential Steering Differential Steering maintains full power to both tracks for best-in-class turning, even with a full blade load. When one track speeds up, the other slows down an equal amount, so you have better maneuverability and faster cycle times. You also get better load capacity, power and speed control in soft conditions because both tracks are powered during turns.

Planetary Power Shift Transmission The proven mechanical transmission features three speeds forward and three speeds reverse. Large diameter, high capacity, oil-cooled clutches provide higher torque capacity and increase service life. Modular components offer easy service access.

Load Sensing Hydraulics Field-proven system senses the load and continuously adjusts hydraulic power to maximize your efficiency. A dedicated implement pump ensures adequate available hydraulic power.

Torque Divider A single stage torque divider sends 70 percent of engine torque through a converter and the other 30 percent through a direct drive shaft so you get more power to the ground.

Cooling System The Advanced Modular Cooling System has excellent cooling capacity with increased air flow, allowing the machine to work in the most demanding environments. Two-pass cooling increases the relevant surface area for maximum cooling capacity. Individual radiator cores can be quickly replaced for ease of service.

Tough from the inside out

BENEFITS AND FEATURES

Structures The foundation of every Cat dozer is a rugged mainframe built to absorb high impact shock loads and twisting forces. Castings add strength to the main case and equalizer bar saddle. The pivot shaft runs through the mainframe and connects the roller frame for independent oscillation. This provides strength, and allows the machine to better follow ground contours for maximum traction and operator comfort. The D8R features the tag-link design to mount the blade closer to the machine for excellent maneuverability, balance and blade penetration. The tag-link provides solid lateral stability and eliminates the need for diagonal bracing.

Bulldozers High tensile strength steel, with a strong box-section design, stands up to the most severe applications. Heavy moldboard construction and hardened bolt-on cutting edges and end bits add strength and durability. Optional rock guards and deflector shields help protect cylinders. High-Capacity Universal, Semi-Universal and Angle Blades are available, as well as special blades for landfill applications. Optional Dual Tilt improves load control and allows the operator to optimize the blade pitch angle for better balance and productivity. Tilt the blade forward for better penetration, then tilt back to increase carrying capacity.

Rear Implements Single and multi-shank adjustable parallelogram rippers are made to penetrate tough material fast and rip thoroughly for use in a variety of materials. Single-Shank ripper depth can be adjusted from the seat using an optional pin puller. An optional push block provides additional weight when needed for tougher conditions. Multi-Shank rippers tailor the tractor to the material by using one, two or three shanks. Rear counterweights optimize balance for backing up steep slopes or increasing performance in heavy dozing applications. The D8R can also be outfitted with a winch. Please see your Cat dealer for available options to suit your applications.

Undercarriage The elevated sprocket design helps protect major components from harsh impacts and provides a modular design for convenient service. A fully suspended undercarriage provides more ground contact, especially in hard, uneven terrain. Greater traction means less slippage, better balance and a smoother ride. An optional non-suspended undercarriage is available for working in low to moderate impact abrasive conditions. Sealed and Lubricated Track is standard on the D8R. The Cat Positive Pin Retention system is designed for high-impact and high load applications. The exclusive Caterpillar design locks the link to the pin to ensure internal lubrication between track pin and bushing is maintained. Lifetime lubricated idlers and track/carrier rollers provide the ability to re-use internal components and rebuild or reshell components for reduced owning and operating costs.

When uptime counts

BENEFITS AND FEATURES

Ease of Service Simple mechanical systems support easy maintenance. Engine, cooling system, power train and undercarriage components are modular, designed for easy repair or maintenance access. The D8R is designed to make daily inspections and routine maintenance more convenient. Service points are grouped and ground-level sight gauges let you inspect fluid levels at a glance. Optional fast-fill fuel and engine oil attachments help you get back to work more quickly.

Renowned Cat Dealer Support Knowledgeable Cat dealers have a global reputation for providing outstanding sales and service. When you need repairs, Cat dealers and our unmatched Caterpillar distribution network excel at getting you the right parts you need quickly. Maximize your equipment investment with a Customer Support Agreement tailored to meet your business needs. Take advantage of preventive maintenance programs like Custom Track Service, Scheduled Oil Sampling (S∙O∙SSM) analysis, and guaranteed maintenance contracts. Cat dealers can even help you with operator training to help boost your profits. Your Cat dealer can also help you maximize your equipment investment with services like Cat Reman parts and Cat Certified Rebuilds. Remanufactured parts offer you the same warranty and reliability as new parts at a fraction of the cost. A Certified Rebuild gives a “second life” for your machine, incorporating the latest engineering updates so you end up with a like-new dozer and a new machine warranty. Caterpillar strives to provide customers the lowest owning and operating costs over the life of their machine.

Product Link™*/VisionLink® Product Link is deeply integrated into your machine. Easy access to timely information like machine location, hours and event codes via the online VisionLink user interface can help you manage your fleet and reduce operating costs. *Product Link not available in all areas. Please consult your Cat dealer.

Cat EMSolutions (Equipment Management Solutions) EMSolutions lets you take control of your fleet with a solution specific to your equipment management needs. Comprehensive, technology-enabled equipment management – combined with the knowledge and expertise of your Cat dealer – can provide ways to help you achieve gains that go straight to your bottom line.

- Improve availability

- Reduce owning and operating costs

- Streamline maintenance practices

- Maximize equipment life

- Increase resale value

Purpose-built for performance

BENEFITS AND FEATURES

D8R Desert Arrangement Caterpillar offers a package of options ideally suited to enhance machine performance in extremely sandy or abrasive underfoot conditions.

- Copper nickel core radiator for added cooling performance.

- Specially coated fan and radiator help resist abrasion.

- Core protection grid.

- Sealed bottom guard and added seals to help keep fine abrasive particles out of components.

- Optional wear plates can be replaced to give you longer blade life when working in abrasive conditions.

D8R WH (Waste Handler) Whether building or closing cells, pushing trash or spreading cover, the D8R WH is designed and built from the frame up to take on the unique challenges of landfill work.

- Specialized guarding, striker bars and seals help protect the machine from impact and airborne debris.

- Bottom and Final Drive guarding help prevent debris from wrapping around or damaging vital components.

- The cooling system is designed for high debris environments, with easy access for cleanout.

- Lights are mounted up and away from main debris area for protection, while still giving you plenty of light on the work area.

- Specialized air intake precleaner helps deliver cleaner air to the machine.

- Landfill blades and trapezoidal-hole track shoes help you optimize your waste handler for the job.